Intelligent solid control system

A solid component and control signal technology, applied in solid separation, mining fluid, centrifuge, etc., can solve problems such as inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

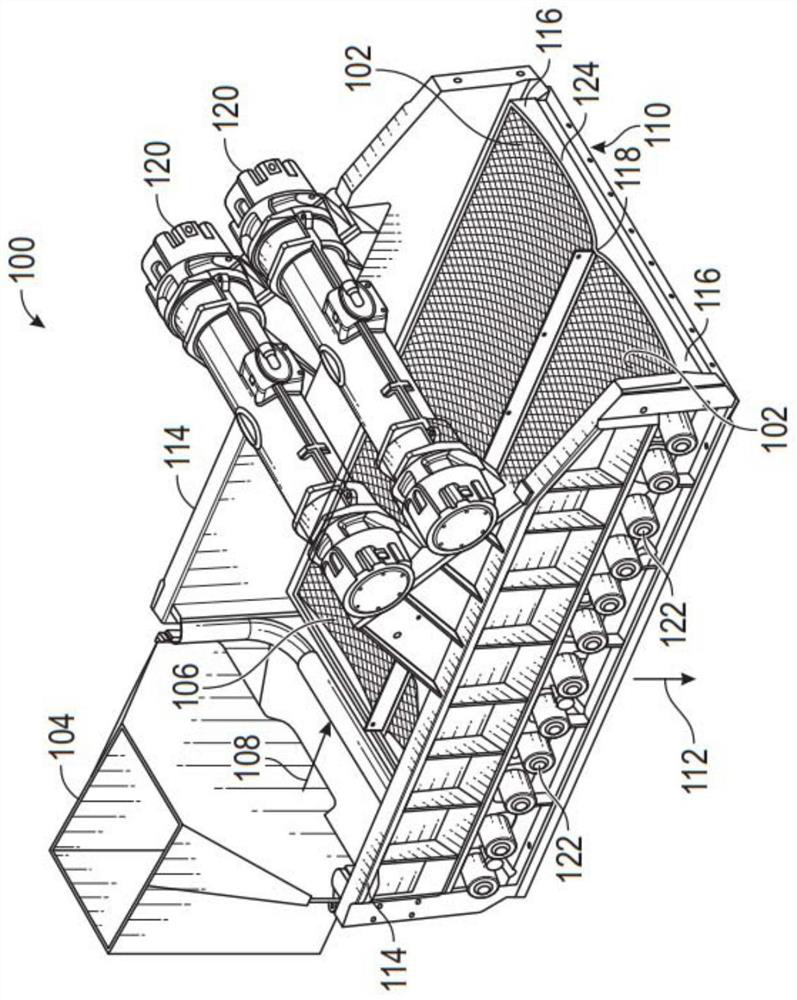

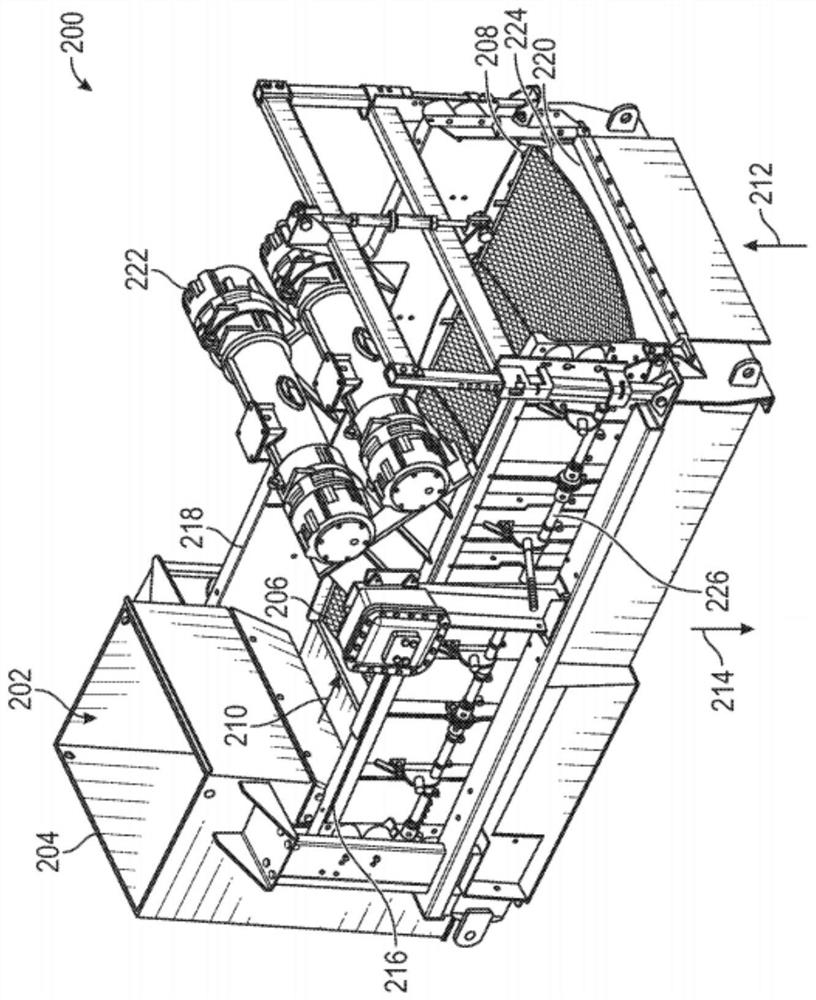

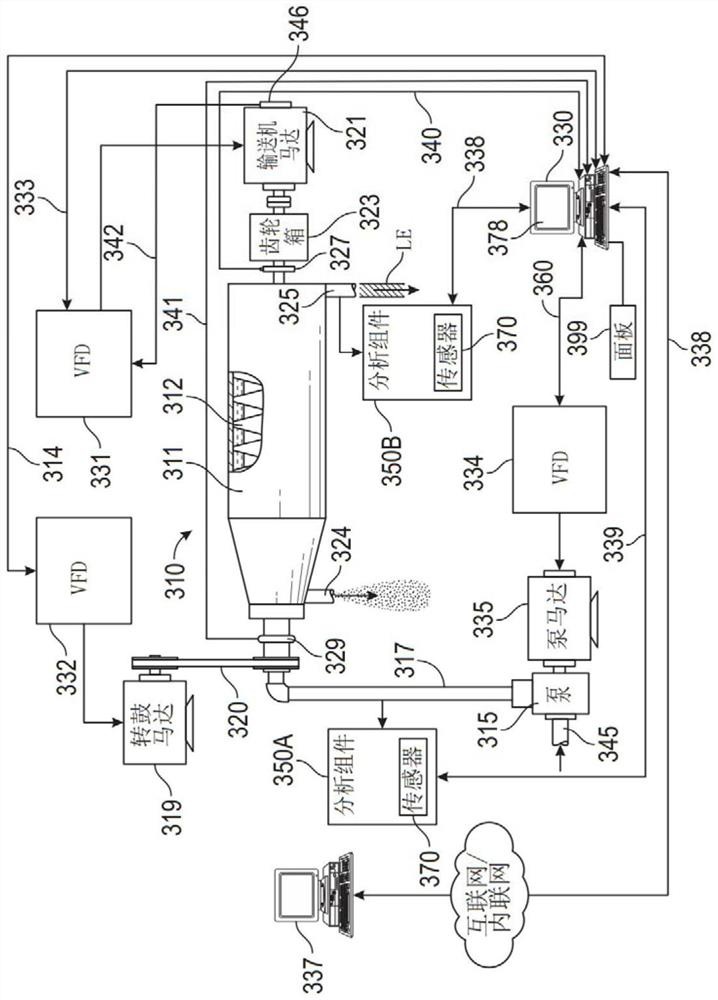

[0062] The present invention generally relates to methods and systems for controlling material separation systems. The materials to be separated may include solid-liquid mixtures, including liquid materials having various particles distributed therein. For example, the mining, oil and gas industries use vibratory screens and centrifuges to separate such materials. For example, when drilling a well, a slurry material (also known as "drilling slurry") may be used to lubricate the drill bit and remove cuttings. One or more shaker machines can be used to remove cuttings and sediment that may accumulate in the slurry. When the material flows through the screen of the vibrating screen, the particles smaller than the opening of the screen pass through the screen together with the liquid in the slurry. Therefore, the first vibratory screen can be used to remove particles with a size larger than the screen opening. Therefore, vibrating screens can be used to change the particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com