Universal needle dial for screen printing machine

A technology of screen printing machine and dial, which is applied in the field of universal dial, which can solve the problems of affecting production efficiency, occupying a large space, wasting time, etc., and achieve the effects of saving time, avoiding contact and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

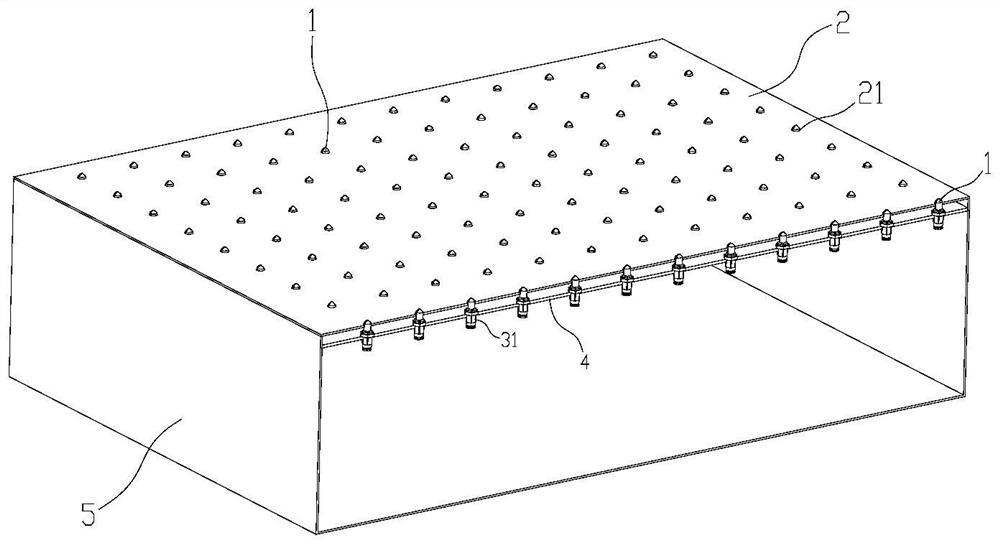

[0036] Figure 1 to Figure 4 The structure of a universal dial for a screen printing machine according to an embodiment of the present invention is schematically shown.

[0037] refer to Figure 1 to Figure 4 , a universal dial for screen printing machine, including thimble 1, pallet 2, lifting device and control device. In addition, the universal dial used for the screen printing machine may also include a base plate 4 and a chassis 5 .

[0038] refer to figure 1 and figure 2 , the number of thimbles 1 is multiple, and the multiple thimbles 1 are distributed in an array.

[0039] refer to figure 1 and figure 2 , a plurality of through holes 21 are formed on the support plate 2, the through holes 21 can be passed through by the thimble 1, the top of the thimble 1 can be tapered, and the thimble 1 with a tapered top can not only make the thimble 1 pass through the through holes smoothly 21, and can effectively reduce the false loss of the thimble 1 to the circuit on th...

Embodiment 2

[0050] Figure 5 to Figure 10 The structure of a universal dial for a screen printing machine according to another embodiment of the present invention is schematically shown.

[0051] refer to Figure 5 to Figure 10 , a universal dial for screen printing machine, including thimble 1, pallet 2, lifting device and control device. In addition, the universal dial used for the screen printing machine may also include a base plate 4 , a chassis 5 and a bracket 7 .

[0052] In this embodiment, the structures of the support plate 2 , the control device, and the chassis 5 are the same as those in the first embodiment, and will not be repeated here.

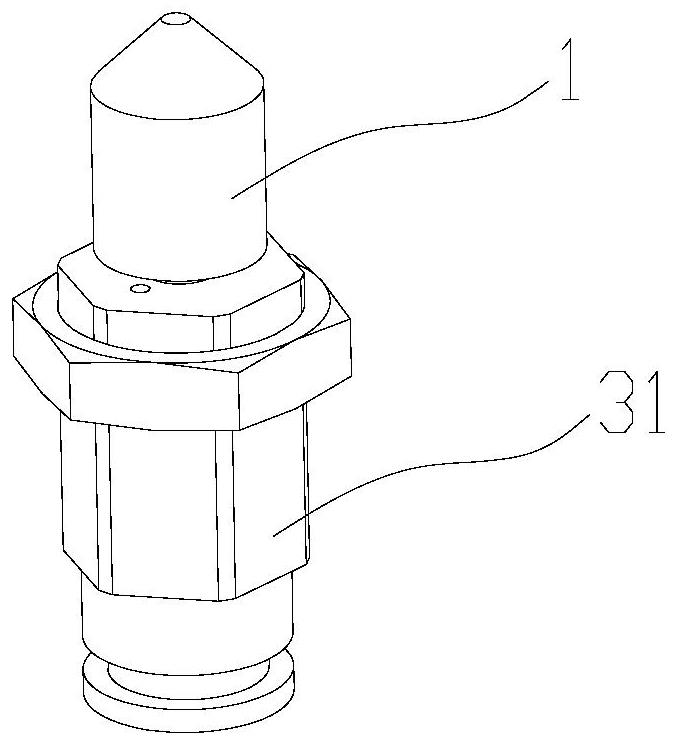

[0053] refer to Figure 8 and Figure 9 , the thimble 1 is divided into upper and lower sections. The cross section of the thimble 1 near the top of the thimble 1 is polygonal, such as a regular hexagon. The lower section of the thimble 1 is formed with an external thread 11. The top of the thimble 1 is tapered. The bottom is formed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com