New energy ship battery drying box

A drying box, new energy technology, applied in secondary batteries, dry gas layout, battery pack components, etc., can solve the problems of desiccant soaking, battery moisture damage, loss of drying performance, etc., to avoid dumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

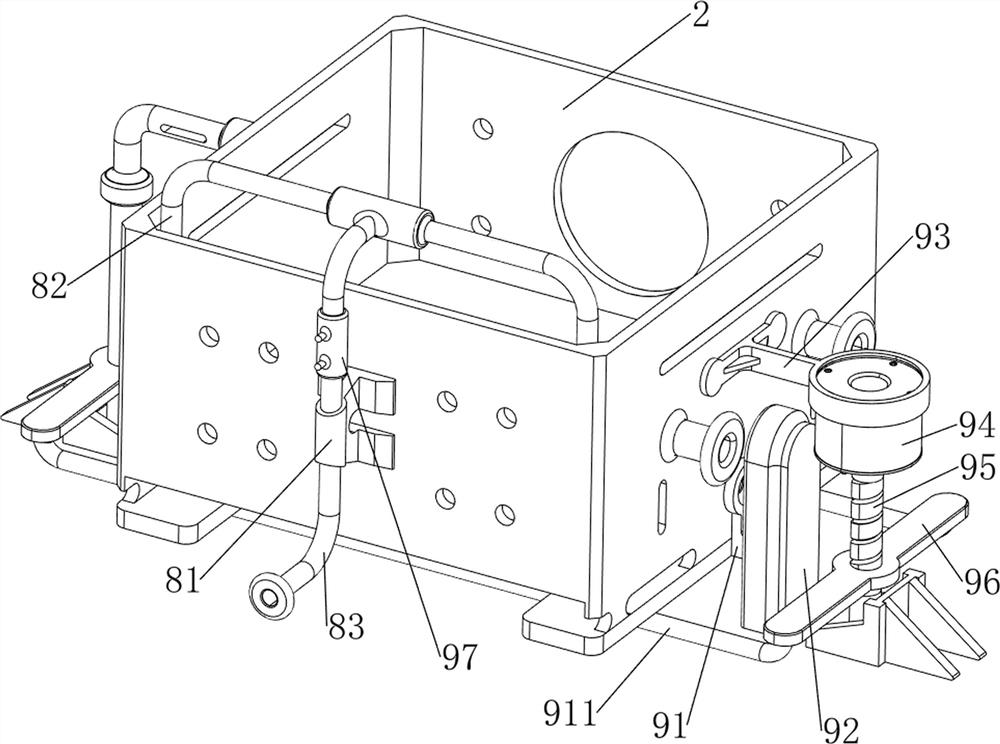

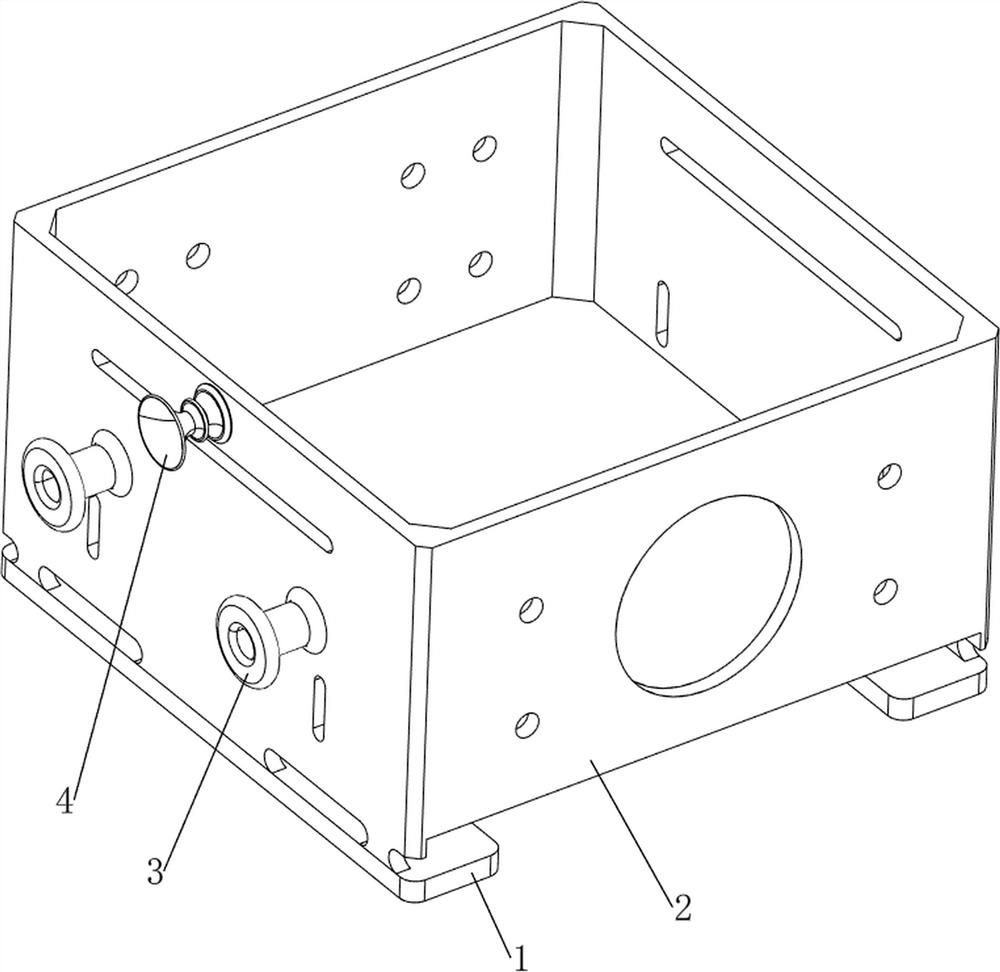

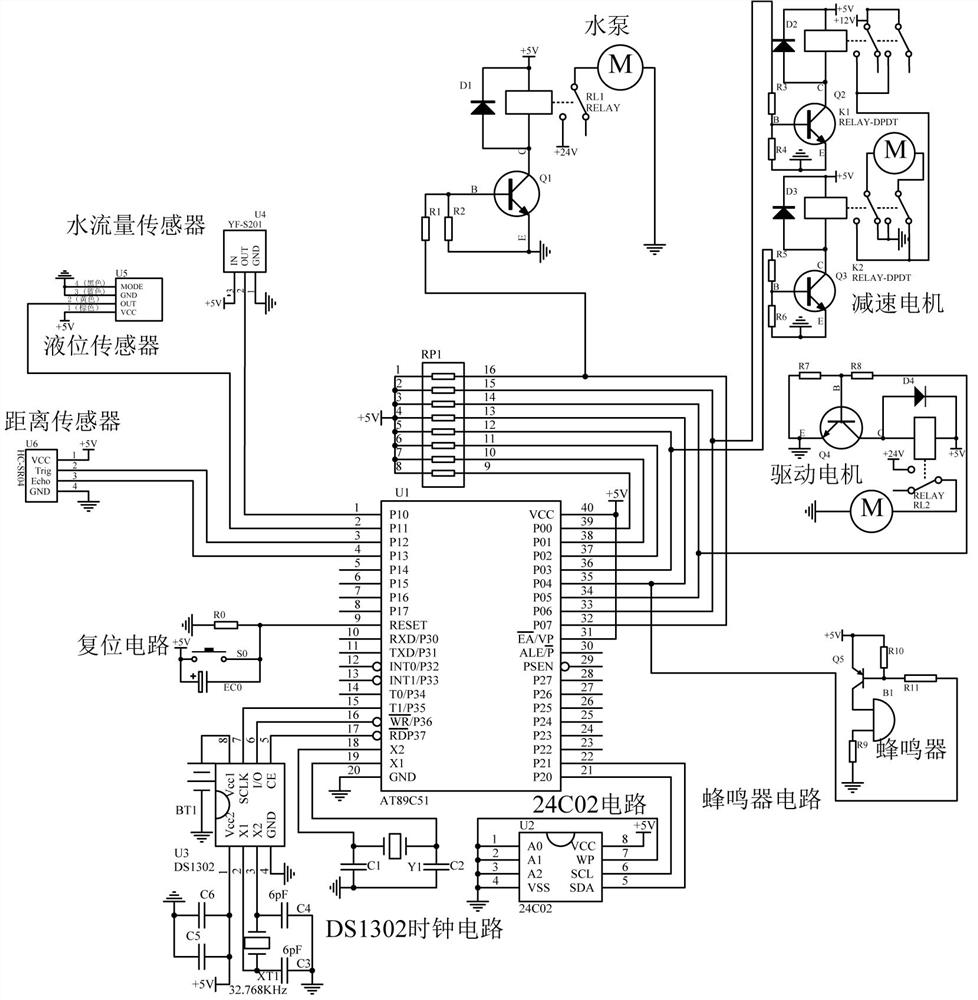

[0084] A new energy ship battery drying box, refer to Figure 1-11 , including a bottom plate 1, an outer frame body 2, a wiring pipe 3, a buzzer 4, a liquid level sensor 6, a shock absorbing mechanism 7 and a pumping mechanism 8, and the bottom of the outer frame body 2 is provided with two bottom plates 1 and two bottom plates 1 The left and right sides of the outer frame body 2 are arranged symmetrically. Two wiring tubes 3 are arranged on the left side of the outer frame body 2. The two wiring tubes 3 are arranged symmetrically front and back. The lower part of the wall is provided with a liquid level sensor 6 , the inside of the outer frame body 2 is provided with a shock absorbing mechanism 7 , and the rear side of the outer frame body 2 is provided with a pumping mechanism 8 .

[0085] refer to Figure 5 , the damping mechanism 7 includes an inner frame body 71, a limit plate 72, a first slide bar 73 and a shock absorbing spring 74, and the outer frame body 2 is slidab...

Embodiment 2

[0093] On the basis of embodiment 1, refer to Figure 12 , also includes an anti-tilt mechanism 11, the anti-tilt mechanism 11 includes a support rod 111, a second sliding sleeve 112 and an arc spring 113, the bottoms of the two special-shaped slide rails 92 are provided with a second sliding sleeve 112, and the second sliding sleeve The inside of 112 is slidably provided with a support rod 111, and two arc springs 113 are connected between each support rod 111 and the second sliding sleeve 112 on the same side.

[0094] Fix the support rod 111 on the ship, when the ship shakes, the second sliding sleeve 112 will slide on the support rod 111, and the arc spring 113 acts as a buffer, and then drives the outer frame body 2 through the slider 91 and the special-shaped slide rail 92 Swing slightly so the appliance will not tip over.

[0095] refer to Figure 13-15 , also includes a closing mechanism 12, the closing mechanism 12 includes a cover plate 121, a second mounting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com