Flotation concentrate grade detection method based on multi-parameter feature fusion

A technology of feature fusion and flotation concentrate, which is applied in the direction of color/spectral characteristic measurement, measuring device, specific gravity measurement, etc., can solve the problems of ray-type grade meter danger, difficult management, health hazards of employees in the surrounding environment, etc., and achieve improvement Model performance and stability, overcoming errors, compensating for the effects of reduced instrument accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

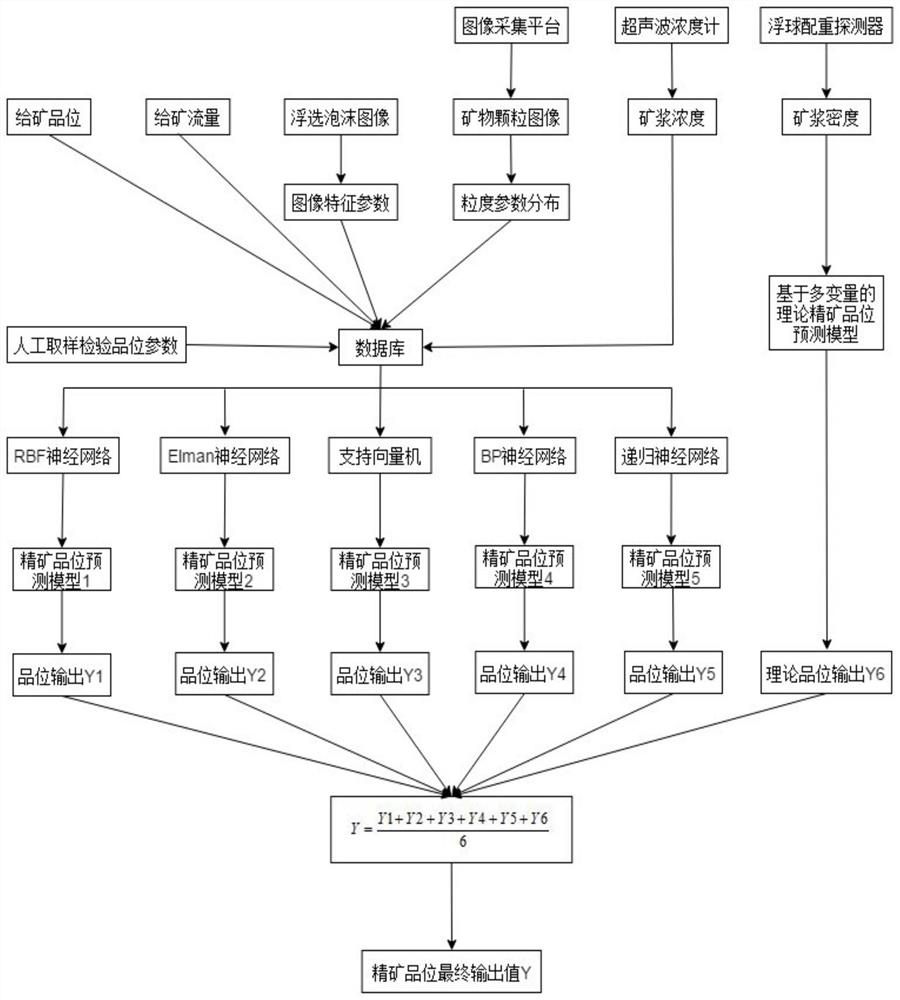

[0085] Such as Figure 1-2 As shown, the present invention is based on the flotation concentrate grade detection method of multi-parameter feature fusion, is characterized in that comprising the steps:

[0086] Step (1) Use a high-precision industrial camera (MV-VS030FC-L model) to collect images of flotation mineral particles and flotation foam;

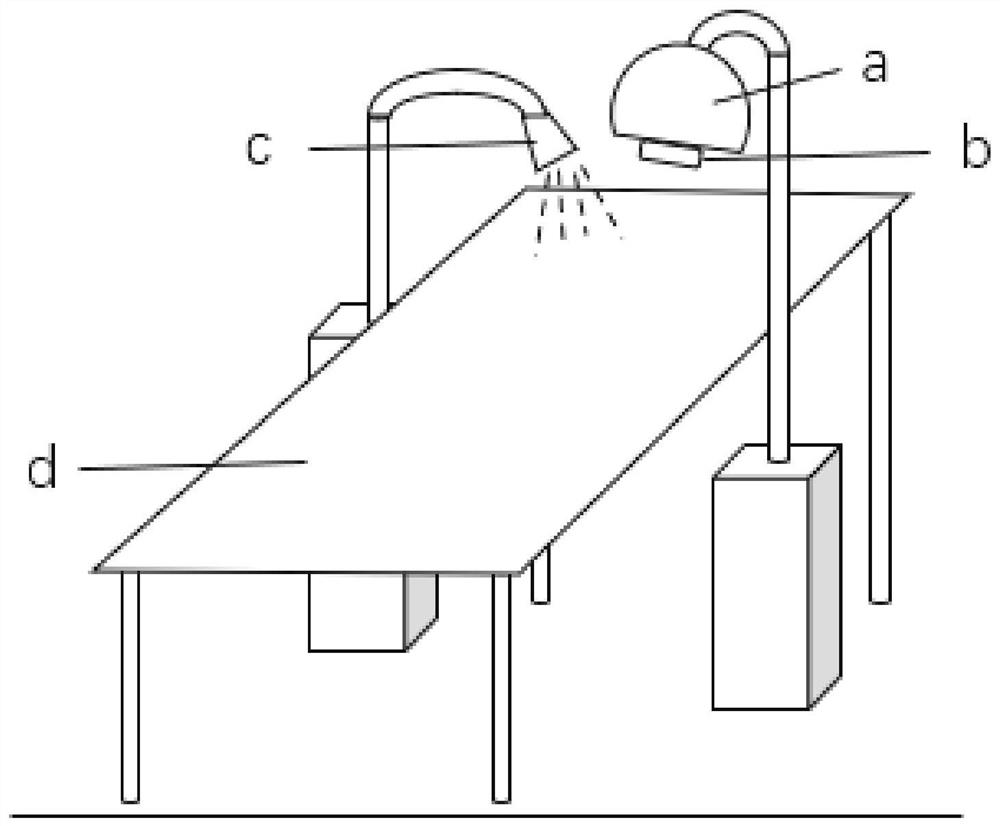

[0087] The step (1) is to fix a high-precision industrial camera directly above the flotation tank, use the dynamic mechanical arm to grab the rod head part of the pulp sampling device, dip into the flotation tank, extract the sediment at the bottom of the pulp, and extract the extracted The slurry sample is poured in such as figure 2 On the slurry chute d of the mineral particle image collection platform shown, the material of the slurry chute is a thick glass plate coated with aluminum film. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com