Reaction device and method for integrated enhanced iron-carbon micro-electrolysis-ozone coupling treatment of nitrobenzene wastewater

A technology of nitrobenzene wastewater and iron-carbon strengthening, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of iron-carbon micro-electrolysis efficiency reduction, low utilization rate, and passivation of fillers Inactivation and other problems, to achieve the effect of reducing the amount of ozone and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

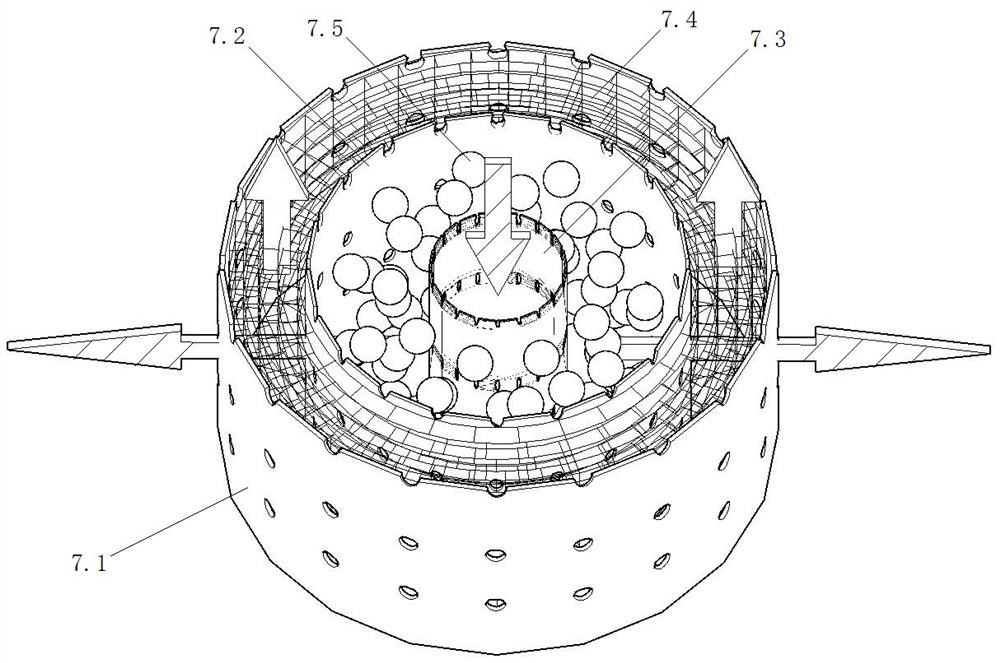

[0042] This embodiment provides an integrated reaction device for strengthening iron-carbon micro-electrolysis-ozone coupling treatment of nitrobenzene wastewater, including an oxygen cylinder 1, an ozone generator 2, a rotating packed bed 6, a centrifugal pump 9, and a nitrobenzene wastewater storage solution Groove 10, rotating packing bed 6 is provided with an annular rotor 7; the rotor 7 is provided with a rotor shell 7.1, an annular partition 7.2 and a rotor inner shell 7.3 in turn from the outside to the inside, the rotor shell 7.1, the annular partition 7.2 and the rotor The inner casing 7.3 is provided with through holes, and the wire mesh 7.4 made of metal wire coils is filled between the rotor outer casing 7.1 and the annular partition 7.2 to form an oxidation zone; the annular partition 7.2 and the rotor inner casing 7.3 are stacked with Iron carbon balls 7.5 form a reduction zone; the gap between the rotor shell 7.1 and the rotating packed bed shell is filled with l...

Embodiment 2

[0053] The present embodiment provides a method for strengthening iron-carbon micro-electrolysis-catalytic ozonation to treat nitrobenzene wastewater, comprising the following steps:

[0054] A method for strengthening iron-carbon micro-electrolysis-ozone coupling treatment of nitrobenzene wastewater is provided, comprising the steps of:

[0055] Put the nitrobenzene wastewater into the rotary packing bed 6 in the above reaction device, so that the refractory nitrobenzene is reduced to easily degradable aniline through the electrolysis of iron-carbon micro-electrolysis in a high-gravity environment, and at the same time, after the electrolysis reaction A lot of Fe 2+ Released into wastewater; wastewater carries Fe 2+ Throw it into the wire mesh 7.4 in the rotor 7, contact with the ozone cross-flow, fully react, deeply oxidize and degrade the organic matter in the waste water.

[0056] The specific process is: the centrifugal pump 9 drives the nitrobenzene waste water in the ...

Embodiment 3

[0070] use figure 1 The device shown treats nitrobenzene wastewater. The initial concentration of nitro compounds in the wastewater was 200 mg / L, and the pH value was 1. The volume of iron-carbon balls 7.5 in the reduction zone is 400 mL, the ratio of iron-carbon content is 5:1, the rotation speed of the frequency conversion motor 8 of the rotating packed bed 6 is 800 rpm, and the gas flow meter 3 is adjusted so that the liquid-gas ratio of wastewater to ozone is 1.5 L / L, the ozone concentration is 30 mg / L. The nitrobenzene wastewater of 2 L was placed in the nitrobenzene wastewater storage tank 10, and was circulated in the rotary packed bed 6 with a flow rate of 80 L / h by the centrifugal pump 9 for 60 min, and the removal rate of nitrobenzene was 100%. %, the mineralization rate is 80%.

[0071] Instead of using high-gravity technology, the micro-electrolysis-high-gravity-catalytic ozonation method is directly used to treat wastewater. When the treatment capacity remains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com