Preparation method of porous carbon and prepared porous carbon

A porous carbon and carbon source technology, applied in the field of porous carbon, can solve the problems of increasing the crushing process and destroying the macroporous structure of the material, so as to achieve the effect of eliminating the spheroidization and crushing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a preparation method of porous carbon, the preparation method comprising:

[0051] (1) Add polymer monomer MMA to deionized water, the molar ratio of deionized water to MMA is 13.7:1, mix and stir at 300r / min, heat up to 60°C and pass nitrogen gas for 20min, add after the temperature is stable The initiator potassium persulfate of 0.05g / L, reacts 3h to obtain described PMMA emulsion;

[0052] (2) PMMA emulsion is mixed with phenolic resin to obtain mixed precursor solution, the concentration of PMMA emulsion in the mixed precursor solution is 1wt%, mixed precursor solution is fed through the atomizing disk of 10000r / min rotating speed with the flow rate of 1kg / h , spray drying at 150°C to obtain a porous carbon precursor;

[0053] (3) The porous carbon precursor is heated up to 600° C. at a heating rate of 1° C. / min, and carbonized for 5 hours to obtain the porous carbon.

Embodiment 2

[0055] This embodiment provides a preparation method of porous carbon, the preparation method comprising:

[0056] (1) Add polymer monomer MMA to deionized water, the molar ratio of deionized water to MMA is 18.7:1, mix and stir at 300r / min, raise the temperature to 65°C and pass nitrogen gas for 23min, add after the temperature is stable The initiator potassium persulfate of 0.1g / L, reacts 2.5h to obtain described PMMA emulsion;

[0057] (2) PMMA emulsion is mixed with phenolic resin to obtain mixed precursor solution, the concentration of PMMA emulsion in the mixed precursor solution is 5wt%, mixed precursor solution is fed through the atomizing disk of 15000r / min rotating speed with the flow rate of 5kg / h , spray-dried at 180°C to obtain a porous carbon precursor;

[0058] (3) The porous carbon precursor is heated up to 700° C. at a heating rate of 3° C. / min, and carbonized for 4 hours to obtain the porous carbon.

Embodiment 3

[0060] This embodiment provides a preparation method of porous carbon, the preparation method comprising:

[0061] (1) Add polymer monomer MMA to deionized water, the molar ratio of deionized water to MMA is 25:1, mix and stir at 350r / min, heat up to 70°C and pass nitrogen gas for 25min, add after the temperature is stable The initiator potassium persulfate of 0.2g / L, reacts 2h to obtain described PMMA emulsion;

[0062] (2) PMMA emulsion and phenolic resin are mixed to obtain mixed precursor solution, the concentration of PMMA emulsion in the mixed precursor solution is 10wt%, mixed precursor solution is fed through the atomizing disc of 20000r / min rotating speed with the flow rate of 10kg / h , spray-dried at 200°C to obtain a porous carbon precursor;

[0063] (3) The porous carbon precursor is heated up to 800° C. at a heating rate of 5° C. / min, and carbonized for 3 hours to obtain the porous carbon.

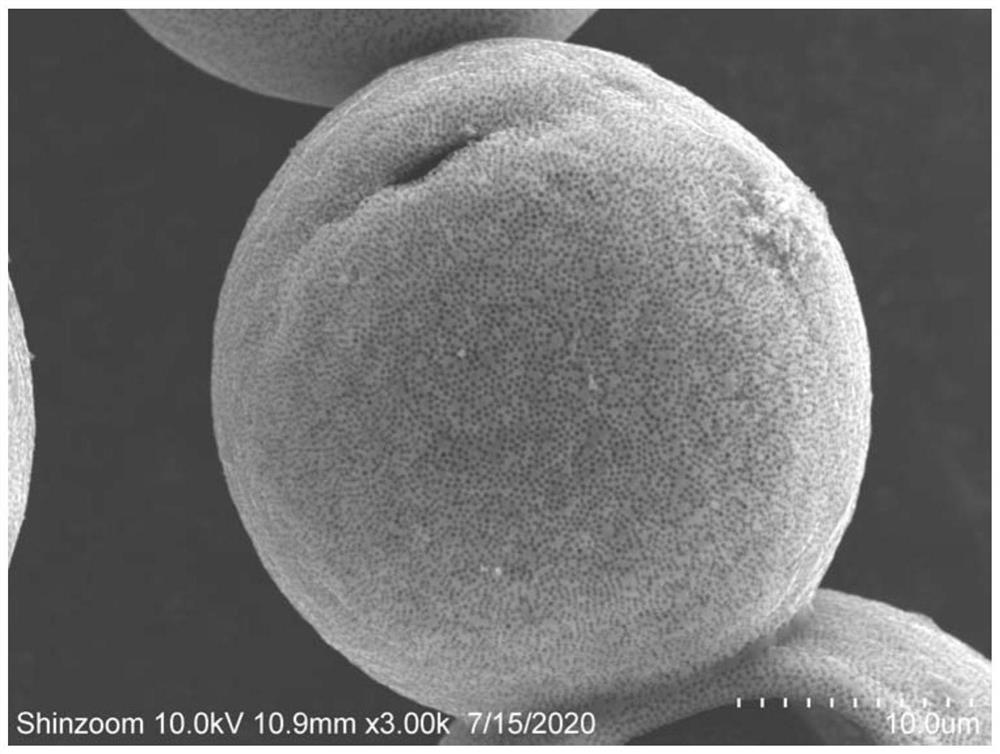

[0064] The electron micrograph of the porous carbon prepared in this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com