Mold for manufacturing crack of biological concrete sample and manufacturing method of crack

A manufacturing method and concrete technology, which is applied in the manufacture of tools, molds, ceramic molding cores, etc., can solve the problems of destroying the shape of the sample, changing the mechanical properties, and failing to generate cracks, so as to ensure the integrity of the shape and the reliability of the performance , Complete mechanical properties, clear and standardized cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

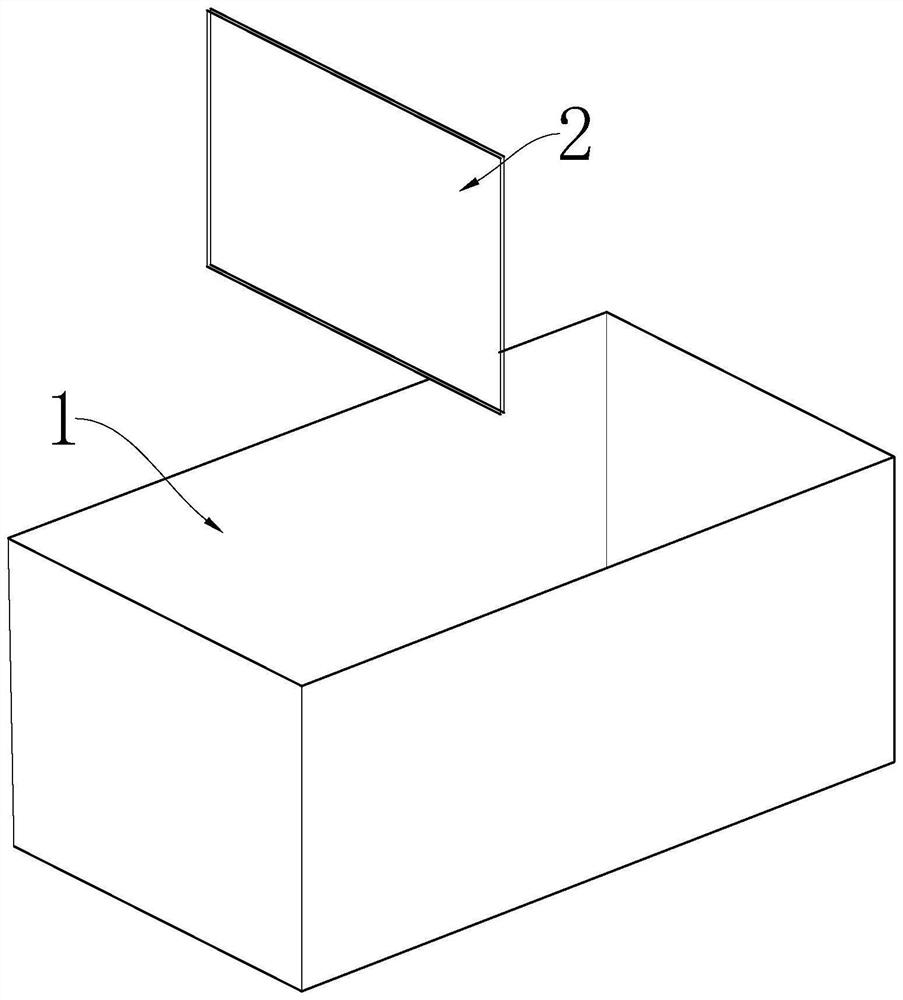

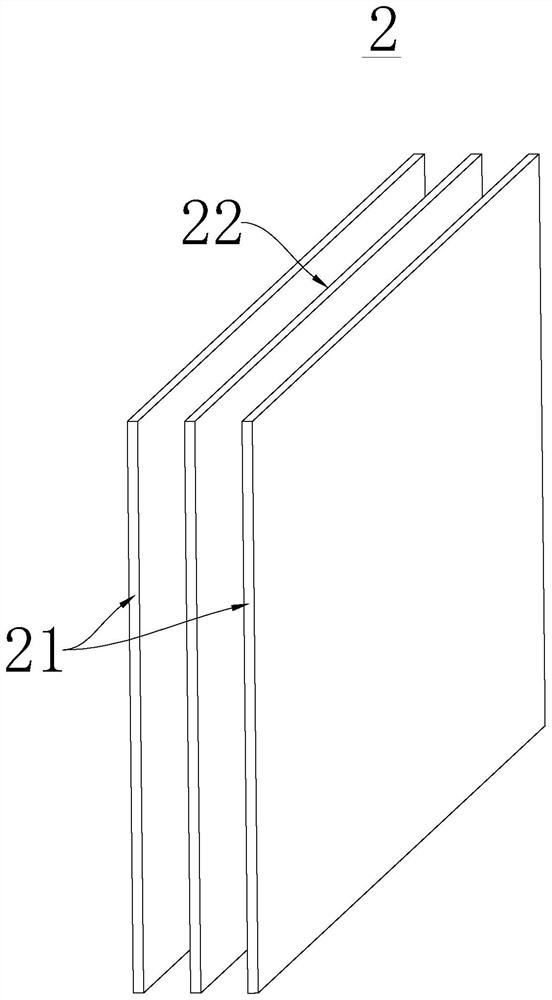

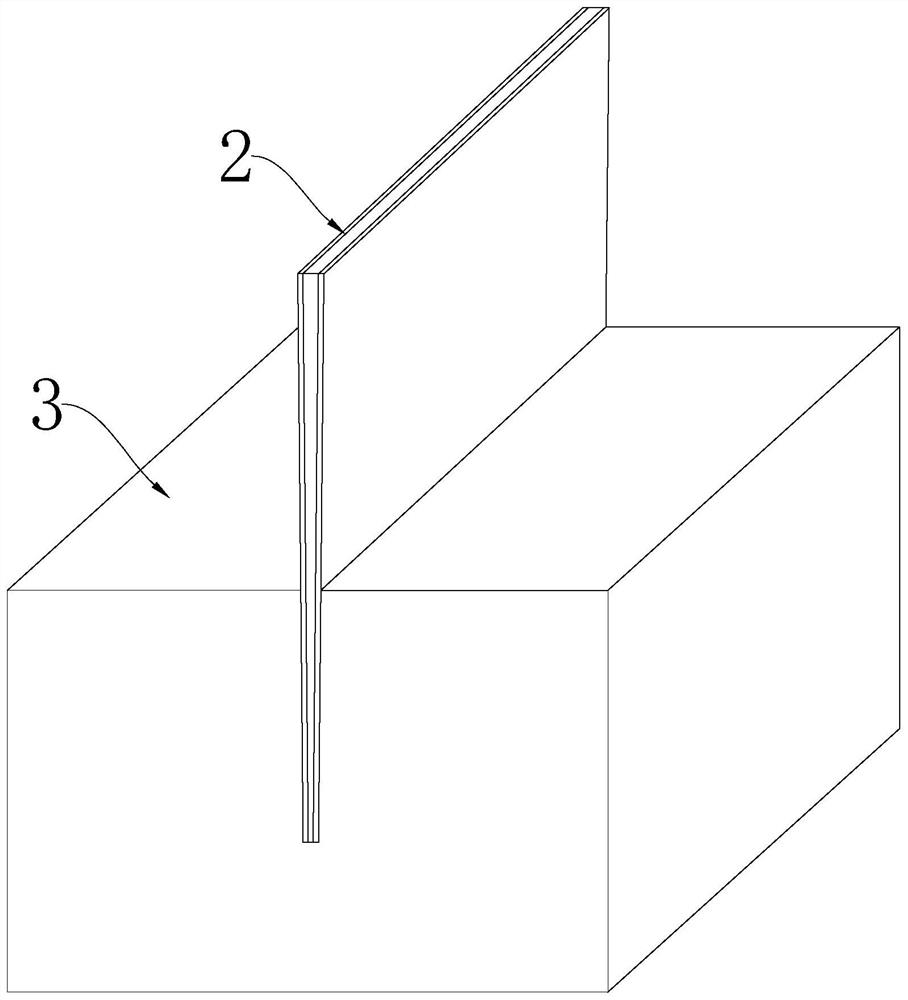

[0048] to combine figure 1 As shown, a mold for making cracks in bio-concrete samples is provided in this embodiment, including a shell 1 and an insert 2, and the shell 1 has a mold for pouring the bio-concrete to form a sample 3. Cavity, the insert 2 is detachably embedded in the cavity for forming cracks in the sample 3, the insert 2 includes a water-soluble film 21, and the dissolution temperature of the water-soluble film 21 is T1, when pouring the bio-concrete into the mold cavity, the pouring temperature of the bio-concrete is T2, the sterilization temperature of the mineralized microorganisms in the sample 3 is T3, and the dissolution of the water-soluble film 21 The temperature satisfies: T2<T1<T3.

[0049] Further, in this embodiment, the insert 2 is used to embed the sample 3 , and when the insert 2 is separated from the sample 3 , a crack is formed in the sample 3 .

[0050]Further, in this embodiment, the connection between the insert 2 and the cavity is used to ...

Embodiment 2

[0070] A kind of manufacturing method of bio-concrete sample 3 cracks, applied the mold among the embodiment 1, described manufacturing method comprises the following steps:

[0071] S1, pouring biological concrete into the cavity of the shell 1 to form the sample 3, the pouring temperature is T2;

[0072] S2, embedding the insert 2 into the sample 3;

[0073] S3. After the pouring of the sample 3 is completed, it is maintained;

[0074] S4. After the curing of the sample 3 is completed, the sample 3 is placed in water at a temperature of T1 to dissolve the water-soluble film 21;

[0075] S5. After the water-soluble film 21 is dissolved, take out the sheet-like frame 22, and dry the sample 3 to obtain a finished product.

[0076] Specifically, the distance between the cracks formed in the sample 3 is 0.1-0.8 mm.

[0077] Specifically, the mineralizing microorganisms in the sample 3 include Bacillus.

[0078] Further, the bacillus is selected from bacillus licheniformis.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com