Rapid forming process for light airplane

A molding process, light aircraft technology, applied in applications, household appliances, household components, etc., can solve the problems of high production cost and long production cycle, and achieve the effect of controlling production cost, excellent processing, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

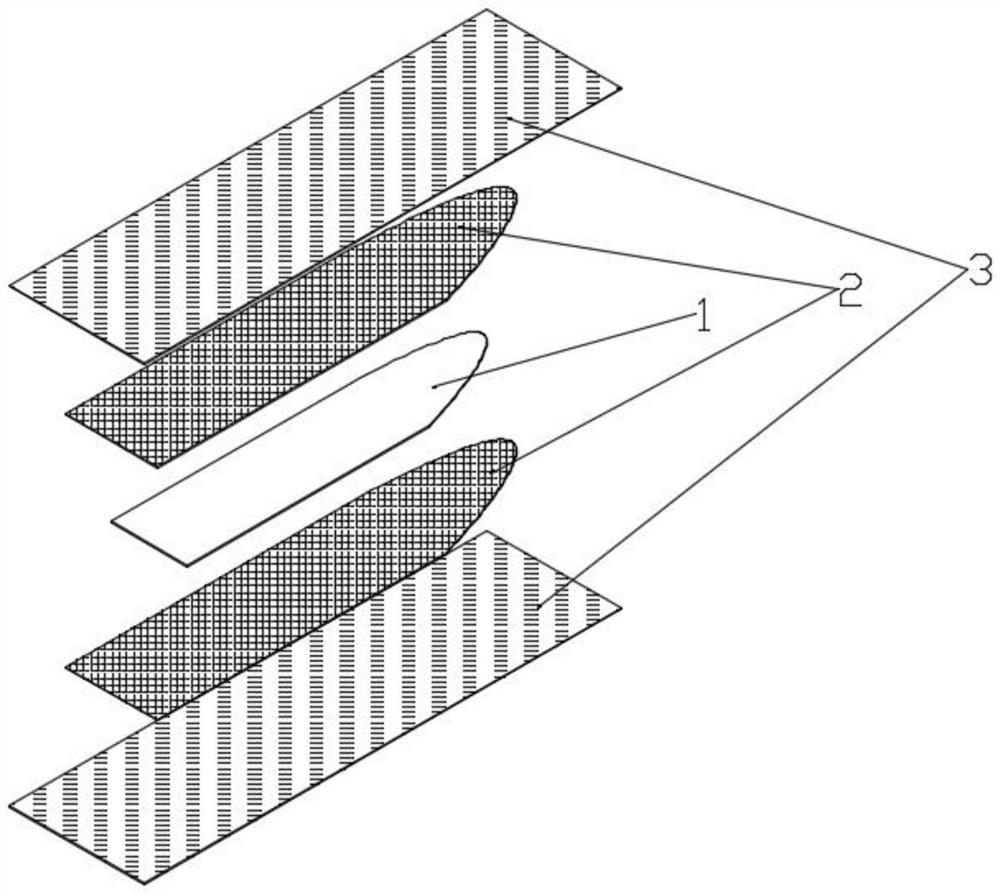

[0038] Example: refer to figure 1 , a kind of rapid prototyping process for light aircraft, comprising the following steps:

[0039] S1: Engraving with the sandwich material of the engraving machine;

[0040] S2: Making products for the sandwich material carved in step S1;

[0041] Step S1 comprises the following steps:

[0042] S101: Use a computer to make a drawing first, and then select the material to be engraved after drawing;

[0043] S102: Engraving the tool for the sandwich material again, engraving and setting the knife for the material to be engraved in step S101, engraving with a density board of appropriate height, and performing a rough engraving with a ball knife to carve out the overall shape;

[0044] S103: For the plate that has been roughly carved in step S102, use a ball knife to perform fine carving on one side of the sandwich material, and after the carving is completed, carve the other side of the plate according to the projection cutting contour;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com