Welding tool for welding evaporation pipe

A technology for welding tooling and evaporating tubes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of general pipe clamping effect, inconvenience, inconvenient fixing of evaporating tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

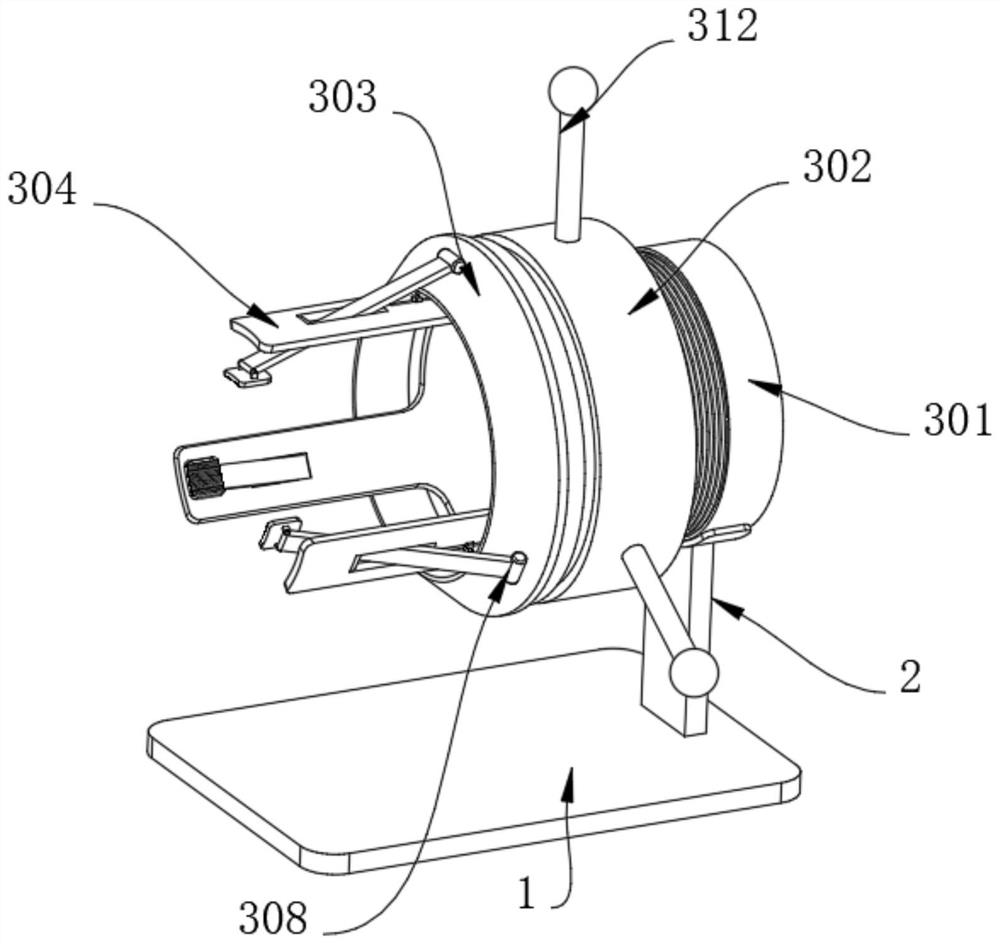

[0041] Example 1, such as Figure 1-8 As shown, the present invention provides a welding tool for evaporating tube welding, including two rectangular plates 1, a backing plate 408 and a clamping structure 3, the upper surfaces of the two rectangular plates 1 are fixedly connected with a support frame 2, and the support frame 2 A clamping structure 3 is provided at the end away from the rectangular plate 1, an adjusting structure 4 is provided at the side where the two rectangular plates 1 are close to each other, and a collecting structure 5 is provided on the upper surface of the backing plate 408.

[0042] The specific settings and functions of the clamping structure 3, the adjusting structure 4 and the collecting structure 5 will be described in detail below.

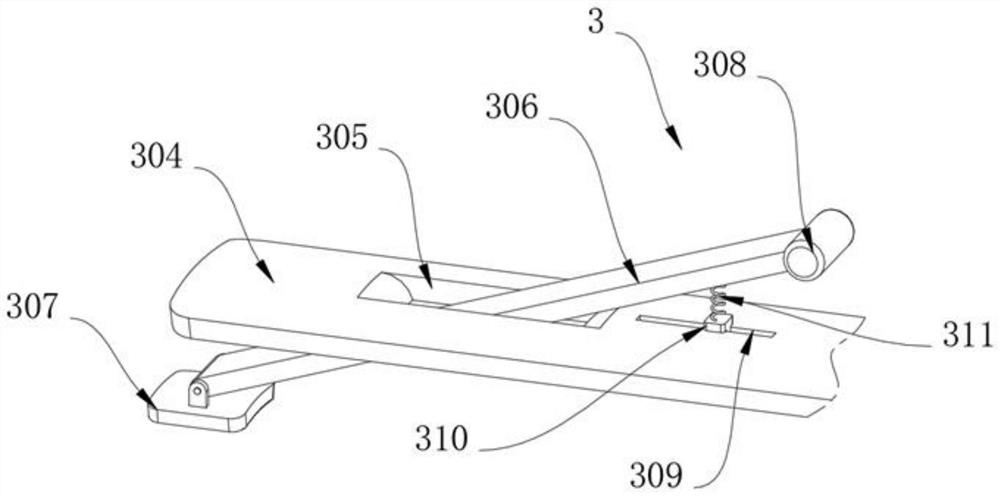

[0043] Such as image 3 and Figure 4 As shown, the clamping structure 3 includes a threaded pipe 301, which is fixedly connected to the upper end of the support frame 2, the circular arc surface of the threaded pi...

Embodiment 2

[0049]Embodiment 2, on the basis of Embodiment 1, the collection structure 5 includes a slide rail 51, the slide rail 51 is fixedly connected to the upper surface of the backing plate 408, the inner wall of the slide rail 51 is slidably connected with a limit bar 52, and the limit bar 52 is away from One side of the inner wall of the slide rail 51 is fixedly connected with a collection box 53, one side of the collection box 53 is fixedly connected with a handle 58, the side of the collection box 53 away from the handle 58 is connected with a slide plate 54, and both sides of the slide plate 54 are provided with slide holes 55. The inner wall of the sliding hole 55 of the sliding plate 54 is slidably connected with a scraper 56. When welding two evaporation tubes, it can cover and collect the waste generated by welding, and the collected waste can also be quickly transferred. , both ends of the scraper 56 are fixedly connected with an elastic rope 57, and the end of the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com