Welding-following ultrasonic-galvanometer scanning composite laser welding system and method

A technology of laser welding and galvanometer scanning, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as differences in ultrasonic introduction positions, achieve the effects of suppressing pore defects, promoting convection, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and The specific operation process. The embodiments described below are only some of the embodiments of the present invention, but not all of them. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

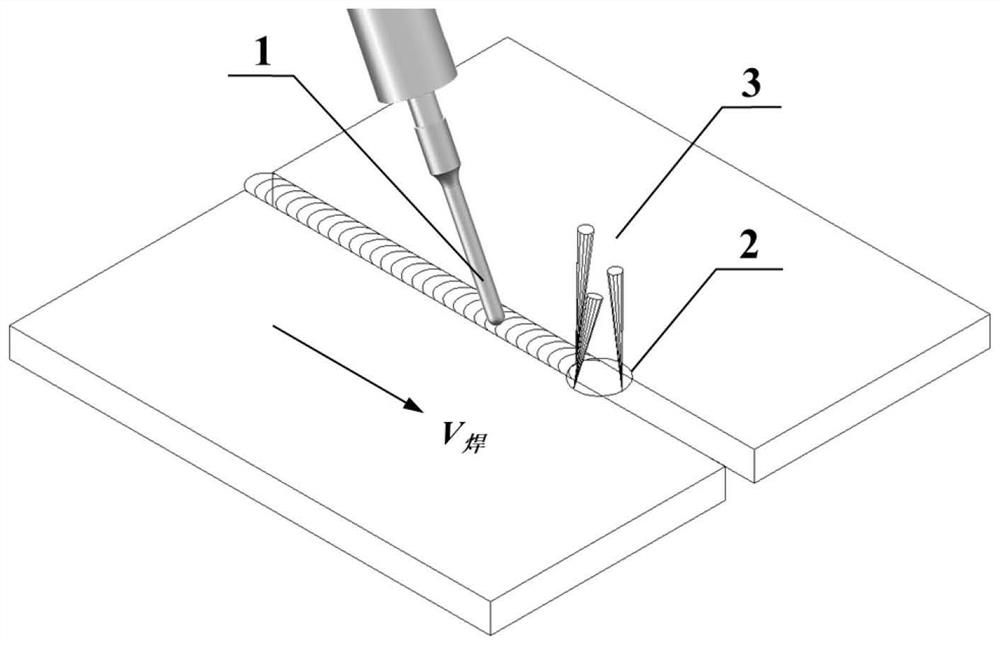

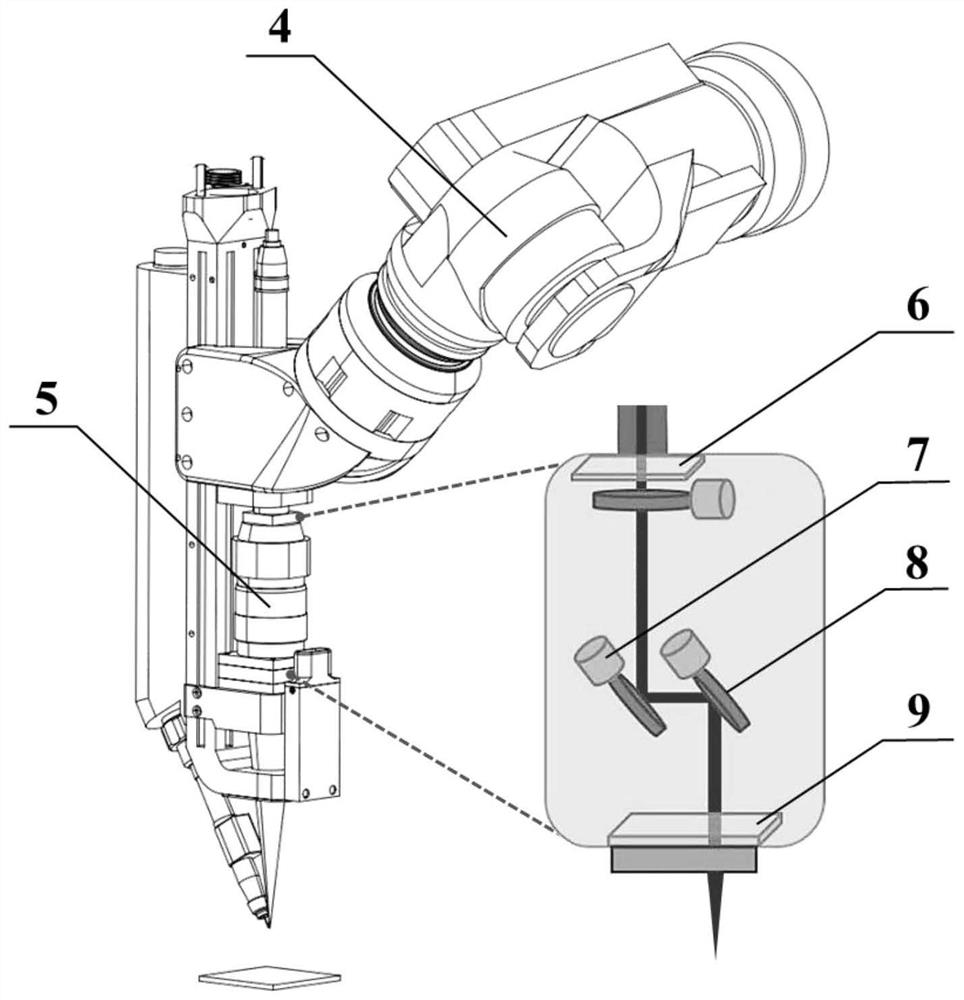

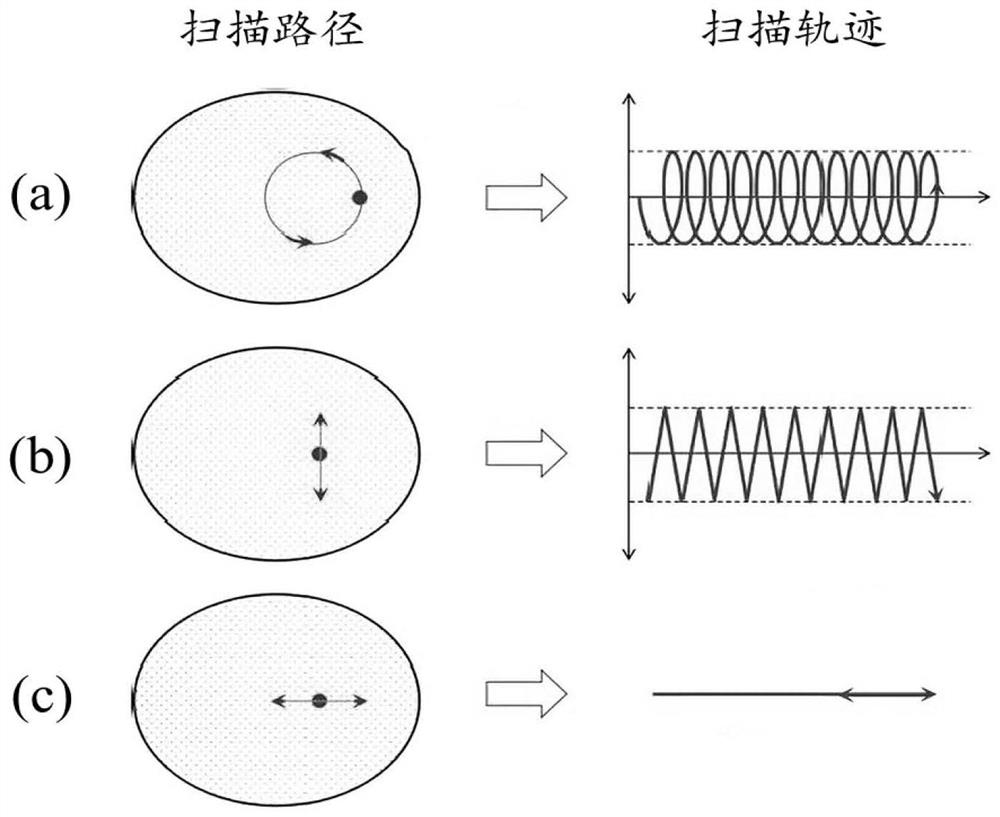

[0056] Such as Figure 1 to Figure 4 As shown, according to the present invention, a welding ultrasonic-galvanometer scanning composite laser welding system and method can be widely used in the fields of aerospace engine casings and the like. The me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com