Mesh bone cement spacer for wrapping cancellous bone grafting for bone defect and preparation method of mesh bone cement spacer

A bone cement and cancellous bone technology, applied in bone implants, manufacturing tools, additive manufacturing, etc., can solve the problems of simultaneous bone grafting and no space for bone grafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

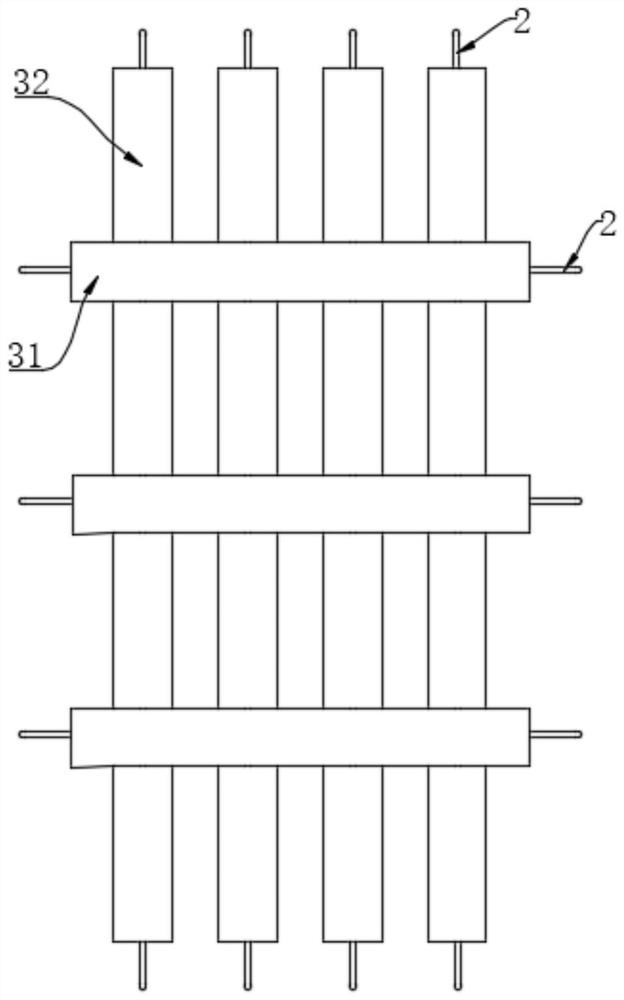

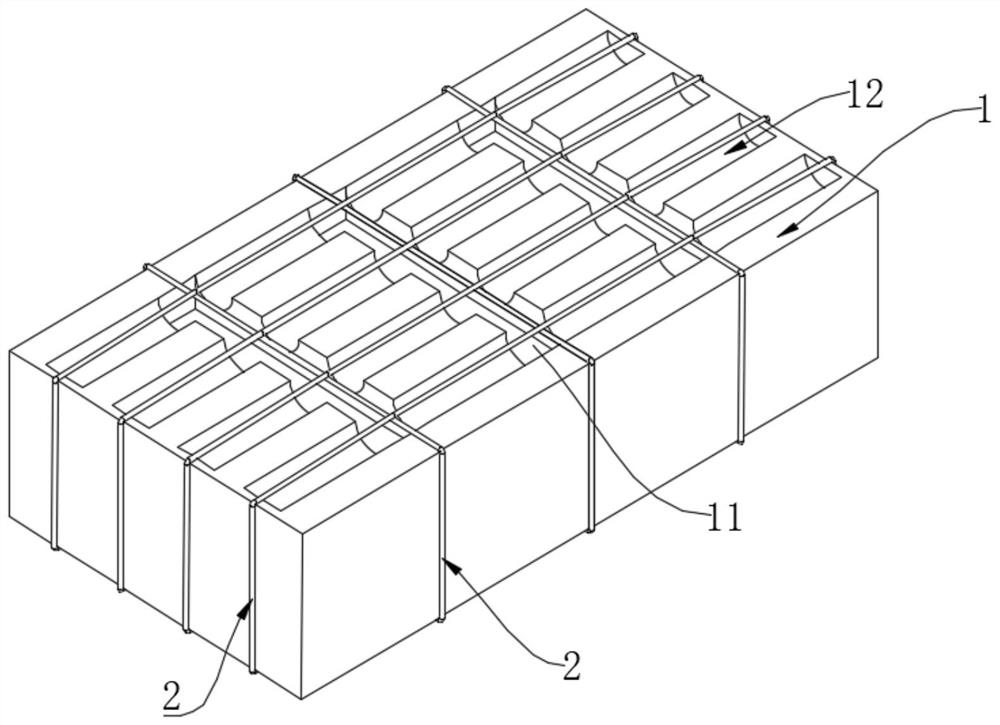

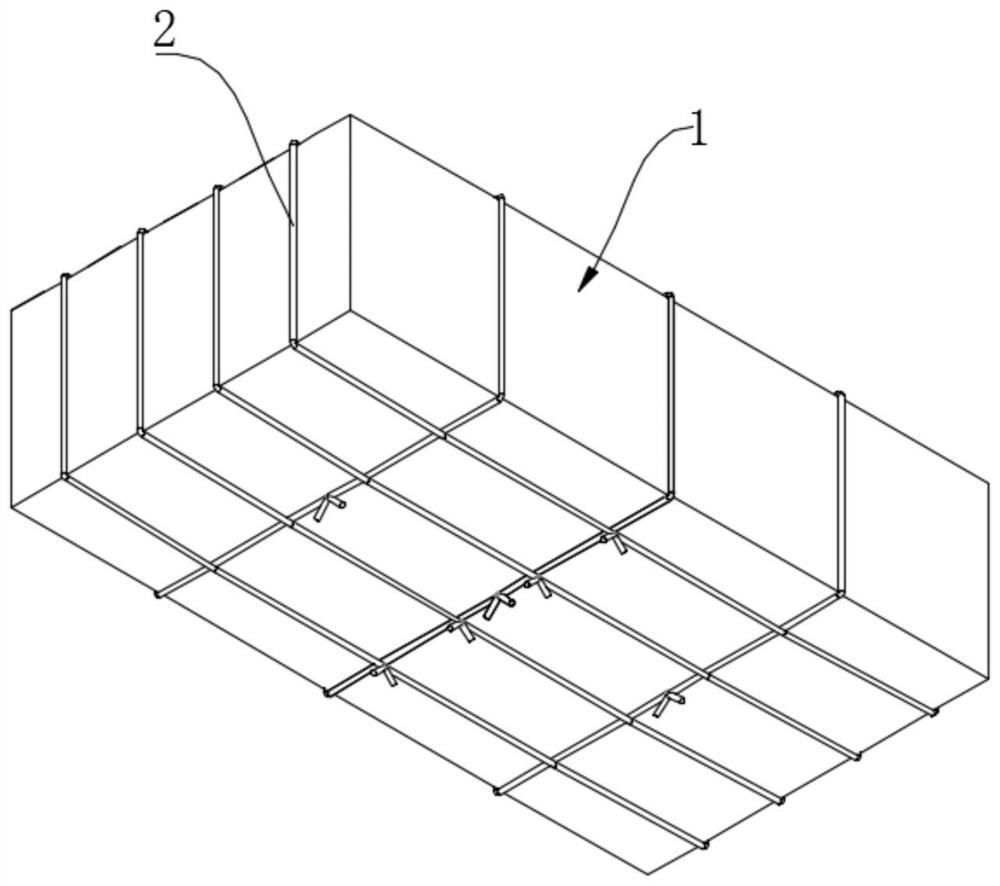

[0034] like Figure 1-Figure 4 shown:

[0035] After debridement, the bone defect in the upper segment of the human tibia has a length of 100mm and a diameter of 60mm, and the two ends of the bone defect are fixed with steel plates 4; the mesh wrapping the bone defect needs to wrap the two stumps by 1cm respectively, so the width of the mesh is 100+10+10=120mm , the length is 60×3.1415=188mm.

[0036] A method for preparing a mesh bone cement spacer wrapped with cancellous bone graft for bone defect, comprising the following steps:

[0037]Step 1: Use foam material to make a mold 1 with 4 horizontal grooves and 30 vertical grooves through 3D printing technology; wherein, the length of each horizontal groove is 188mm, the width is 1mm, and the depth is 1mm; each vertical groove The length of the groove is 120mm, the width is 2mm, and the depth is 2mm; the distance between every two adjacent transverse grooves is 25mm; the distance between every two adjacent longitudinal groov...

Embodiment 2

[0048] like Figure 1-Figure 4 Shown:

[0049] The diameter of the mid-section of the femur of SD rats is 4mm, and the bone defect of the mid-section of the femur of SD rats is made with a bone defect length of 10mm, that is, a 4mm×10mm bone defect, and the two ends of the bone defect are fixed with steel plates 4; the mesh wrapping the bone defect needs to be wrapped separately The two residual sections are 2mm, so the length of the net is 10+2+2=14mm, and the width is 4×3.141=12mm.

[0050] A method for preparing a mesh bone cement spacer wrapped with cancellous bone graft for bone defect, comprising the following steps:

[0051] Step 1: choose a cardboard material to press mold and make a mold 1 with 3 transverse grooves and 5 longitudinal grooves; wherein, the length of each transverse groove is 14mm, the width is 1mm, and the depth is 0.8mm; The length of each longitudinal groove is 12mm, the width is 1.5mm, and the depth is 0.8mm; the distance between every two adjacen...

Embodiment 3

[0061] like Figure 1-4 Shown:

[0062] After debridement, the length of the bone defect in the middle part of the human femur is 60mm, and the diameter of the femur is 50mm. The two ends of the bone defect are fixed with steel plates 4; =80mm, the length is 50×3.14=160mm.

[0063] A method for preparing a mesh bone cement spacer wrapped with cancellous bone graft for bone defect, comprising the following steps:

[0064] Step 1: Use resin material to make a mold 1 with 3 horizontal grooves and 32 vertical grooves through 3D printing technology; wherein, the length of each horizontal groove is 160mm, the width is 1mm, and the depth is 1mm; each vertical groove The length of the groove is 80mm, the width is 3mm, and the depth is 2mm; the distance between every two adjacent transverse grooves is 20mm; the distance between every two adjacent longitudinal grooves is 2mm;

[0065] Step 2: Use a sewing needle to pass No. 1 medical non-absorbable suture through the center of the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com