Exhaust gas after-treatment method for internal combustion engine and motor vehicle having exhaust gas after-treatment system

A technology of exhaust gas post-treatment and internal combustion engine, which is applied in the direction of electronic control of exhaust gas treatment device, exhaust gas treatment, internal combustion piston engine, etc. It can solve problems such as the influence of conversion power, and achieve the effect of high-efficiency conversion and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

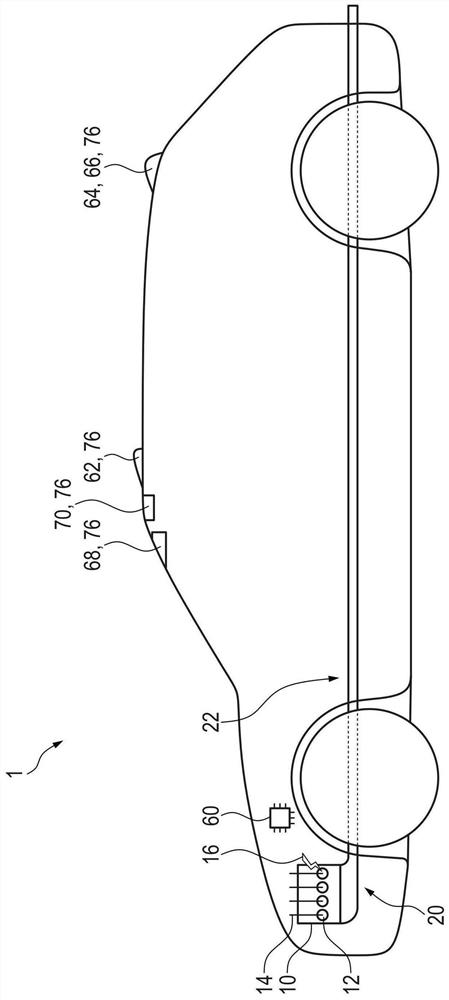

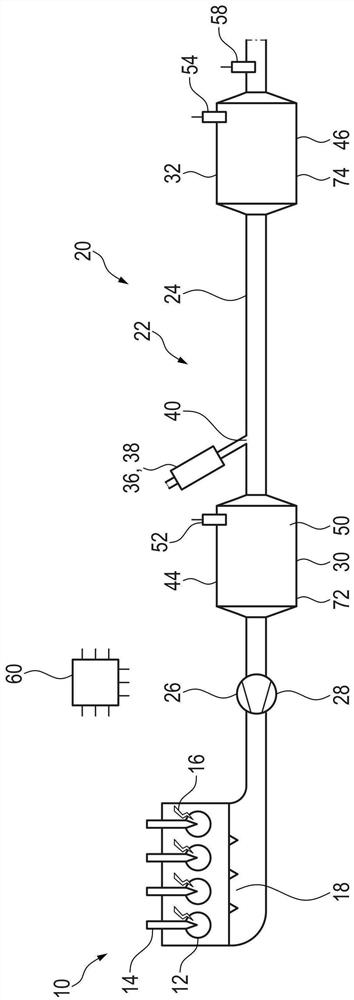

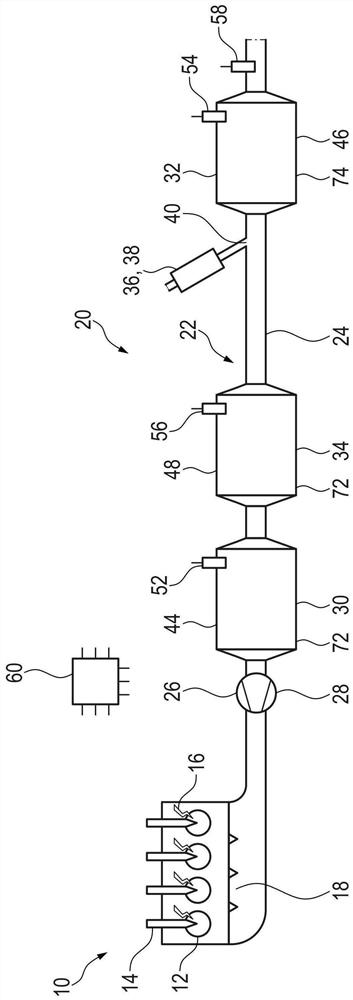

[0031] figure 1 Motor vehicle 1 with internal combustion engine 10 is shown. The internal combustion engine 10 is designed as an externally ignited internal combustion engine 10 according to the Otto principle and has a plurality of combustion chambers 12 on which a fuel injector 14 and a spark plug 16 are respectively arranged. Internal combustion engine 10 is connected via its exhaust port 18 to an exhaust system 22 of an exhaust gas aftertreatment system 20 . The motor vehicle 1 has at least one detector device 76 , preferably a plurality of detector devices 76 , by means of which the surroundings of the motor vehicle, the position of the motor vehicle, the direction of travel, the speed, the surroundings and possibly other parameters can be detected. Detection means 76 may include, in particular, GPS sensor 66 for detecting the position and position changes of motor vehicle 1 . The detection means 76 can also include one or more optical detection means 76 , in particular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com