Construction method for slope surface protection

A construction method and slope technology, applied in botanical equipment and methods, excavation, infrastructure engineering, etc., to achieve the effect of reducing possibility, enhancing bonding force, and simple assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below with reference to the drawings and examples, but the present invention is not limited to the following embodiments.

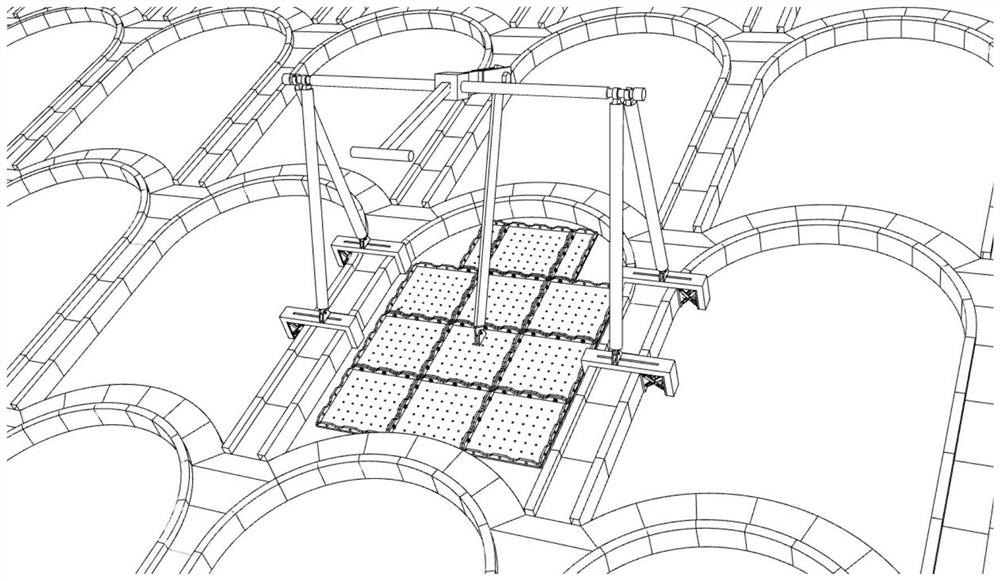

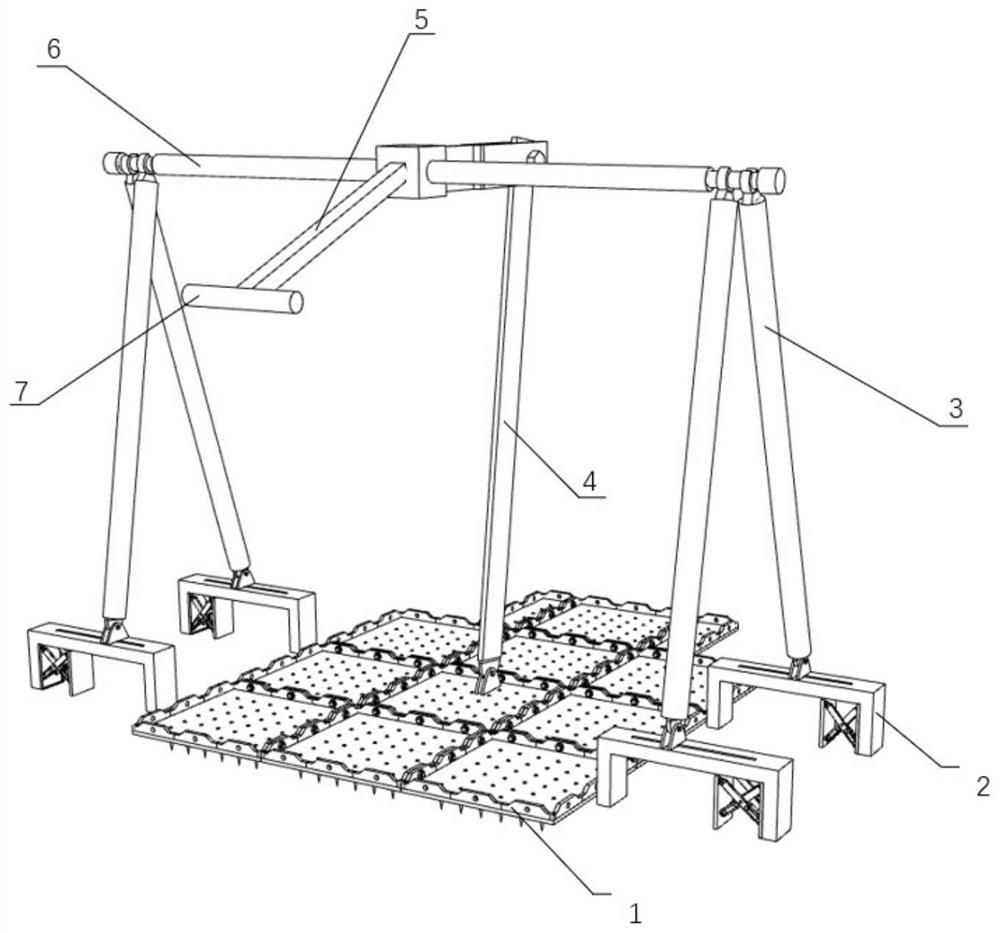

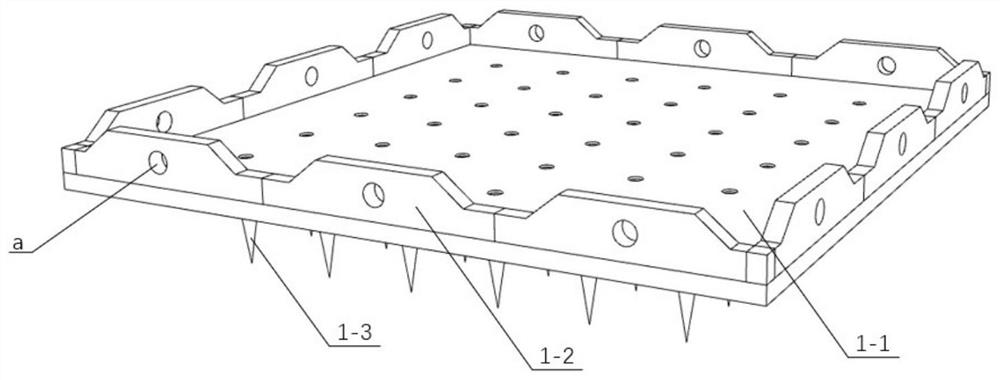

[0028] exist Figure 2-5 Among them, the device used in the construction method for slope protection in this embodiment includes a splicing nail plate 1 and a clamping and pressing mechanism. The splicing nail plate 1 is a breadboard 1-1 with drill holes evenly distributed on the bottom surface Cone 1-3, drilling cone 1-3 specification is 95mm in height, 30mm in bottom diameter, or 65mm in height, 22mm in bottom diameter, or 79mm in height, 22mm in bottom diameter, breadboard 1- 1. Fences 1-2 with connecting holes a are installed around the upper surface. Multiple spliced nail plates 1 are covered on the slope. Adjacent spliced nail plates 1 are connected through connecting holes a on the fence 1-2. The spliced nail plates 1. It is used to form regularly distributed tapered holes on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap