Method for brewing wine by fermenting longan seeds

A production method and technology of longan kernels, applied in the preparation of alcoholic beverages, etc., can solve problems such as bad taste, poor flavor of longan kernel wine, easy methanol exceeding the standard, etc., to promote the separation of effective components, improve flavor, and reduce methanol content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

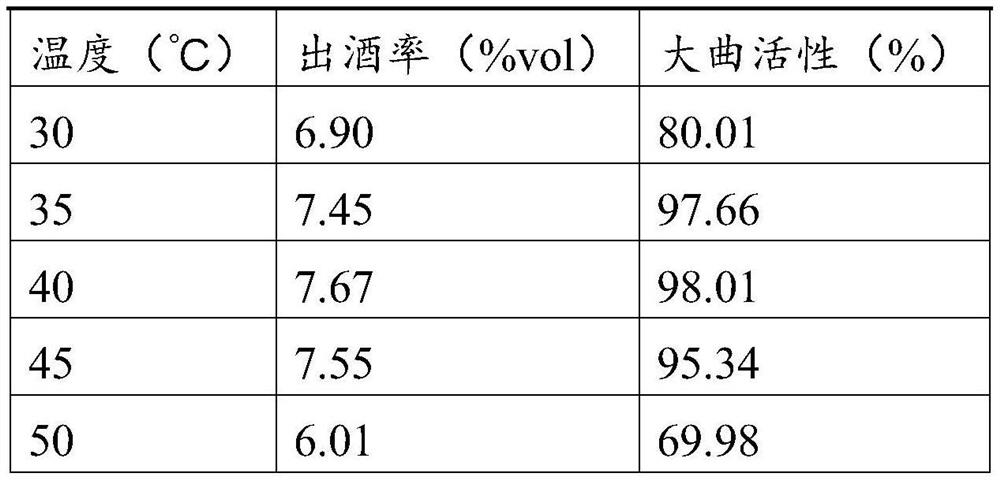

Embodiment 1

[0028] The longan kernels are dried twice in sequence, the first drying temperature is 60°C, and the drying time is 18h, and the second drying temperature is 40°C, and the drying time is 45h, and the dried longan kernels are obtained; then Pulverize, pass through a 60-mesh sieve, and collect the components under the sieve to obtain longan seed powder; stir-fry the obtained longan seed powder with a slow fire until slightly yellow, then steam at 90°C for 30 minutes to obtain fully cooked longan seed powder; After cooling the fully cooked longan kernel powder to 35°C, mix it with 43°C Daqu, which is purchased from Liangshan Thyme Biological Engineering Co., Ltd., and the amount of Daqu is 5‰ of the quality of longan kernel powder. Fermentation is carried out at a temperature of 40°C. ℃, the time is 30 days; then use white wine as a hole filter to filter to get longan core wine.

Embodiment 2

[0030] The longan kernels are dried twice in sequence, the first drying temperature is 55°C, and the drying time is 12h, and the second drying temperature is 35°C, and the drying time is 36h, to obtain dried longan kernels; Pulverize, pass through a 50-mesh sieve, and collect the components under the sieve to obtain longan seed powder; stir-fry the obtained longan seed powder with a slow fire until slightly yellow, then steam at 80°C for 20 minutes to obtain fully cooked longan seed powder; After cooling down to 30°C, the fully cooked longan kernel powder was mixed with 40°C Daqu, which was purchased from Liangshan Thyme Biological Engineering Co., Ltd., and the amount of Daqu was 4‰ of the quality of longan kernel powder. Fermentation was carried out at a temperature of 35°C. ℃, the time is 20 days; then use white wine as a hole filter to filter to get longan core wine.

Embodiment 3

[0032] The longan kernels are dried twice in sequence, the first drying temperature is 65°C, and the drying time is 24h, and the second drying temperature is 45°C, and the drying time is 72h, and the dried longan kernels are obtained; then Pulverize, pass through a 70-mesh sieve, and collect the components under the sieve to obtain longan seed powder; stir-fry the obtained longan seed powder with a slow fire until slightly yellow, then steam at 100°C for 40 minutes to obtain fully cooked longan seed powder; After cooling the fully cooked longan kernel powder to 40°C, mix it with 45°C Daqu, which was purchased from Liangshan Thyme Biological Engineering Co., Ltd., and the amount of Daqu was 6‰ of the quality of the longan kernel powder. Fermentation was carried out at a temperature of 45°C. ℃, the time is 40 days; then use white wine as a hole filter to filter to get longan core wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com