Slag agent for external refining iron and titanium removal of industrial silicon furnace

A technology of silicon furnace and iron removal, which is applied in the direction of silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low content and difficult removal, so as to reduce activity, increase metal yield, and improve purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention provides a silicon-coated refining slag suitable for reducing the content of iron and titanium in industrial silicon. The technical problem solved by the slag agent in the invention is to remove And reduce impurity elements iron and titanium in industrial silicon. It is conducive to improving the purity and grade of industrial silicon, reducing the loss of elemental silicon in the process of blowing refining, shortening the refining time, and improving refining efficiency

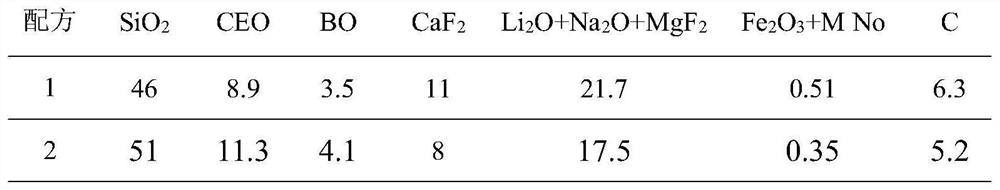

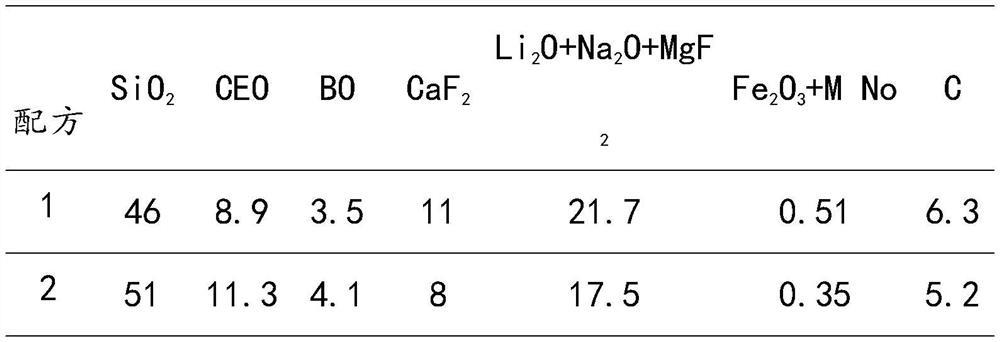

[0017] Specifically, the present invention achieves the above-mentioned purpose by adding and adjusting the chemical ratio of the slag agent, and its chemical composition weight percentage meets: 5%2 2 2 O, Na 2 O, MgF 2 One or two or three of the three components form a combination, 5%2 O2 O2 2 o 3 +M No<1%; the rest are impurities.

[0018] The CEO / SiO 2 0.1 to 0.6.

[0019] The carbon (C) in the composition is provided by one, two or three of graphite, carbon black and coal powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com