Control method capable of obviously reducing cracks of head and tail blanks of wide and thick plate

A control method and technology for wide and thick plates, applied in the field of continuous casting in the metallurgical industry, can solve the problems such as the limited effect of crack control on the head and tail billets, and achieve the effects of shortening the product delivery cycle, improving the surface quality, and improving the incidence of surface cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is to use the control method of the present invention to control the cracks of bridge steel Q345qE head and tail blanks.

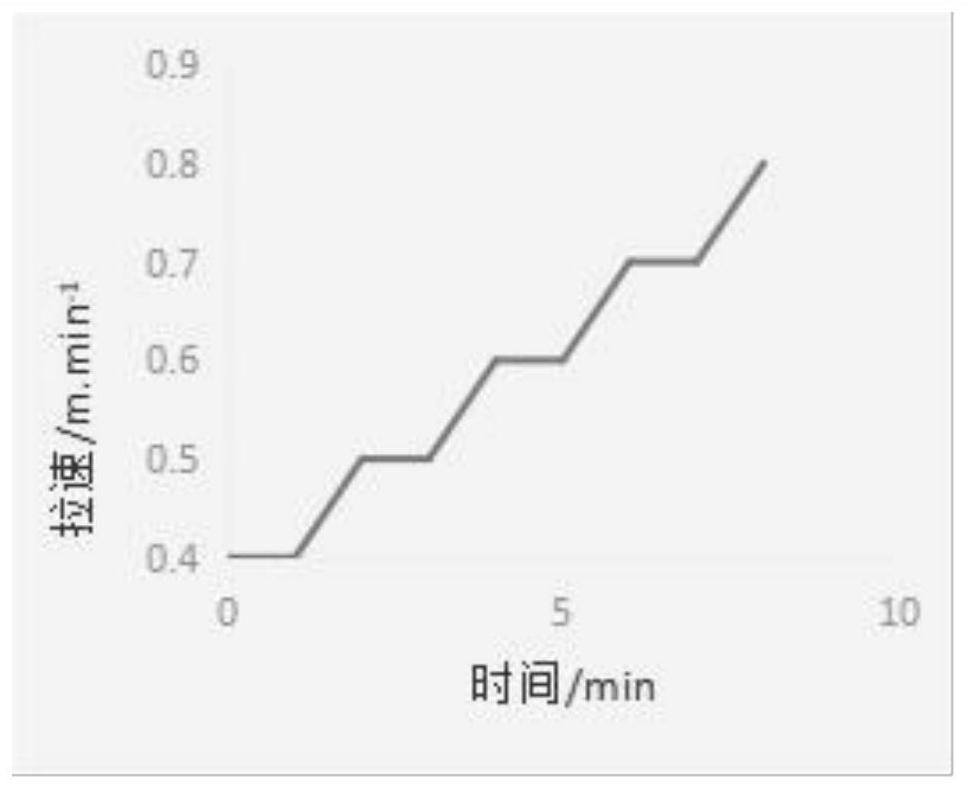

[0036] Set the pre-flushing water 2 minutes ahead of the program before starting the pouring. After starting the pouring equipment, the casting speed will directly reach 0.4m / min, and then stabilize at 0.1m / min after 1min. 2 The acceleration is evenly increased, and the pulling speed is stable for 1 minute every time the pulling speed is increased by 0.1m / min until the normal pulling speed. Push in the special pouring powder when starting the casting, and set the vibration frequency of the crystallizer vibration table to 132Hz and the amplitude to 4.0mm when casting starts. The "red slag" operation is carried out in the tail out stage, and a small amount of water is sprinkled after the stopper is closed, and the time does not exceed 2 seconds.

Embodiment 2

[0038] This embodiment uses the control method of the present invention to control cracks in the wind power steel Q345D head and tail blanks.

[0039] Set the pre-flushing water 2 minutes ahead of the program before starting the pouring. After starting the pouring equipment, the casting speed will directly reach 0.4m / min, and then stabilize at 0.1m / min after 1min. 2 The acceleration is evenly increased, and the pulling speed is stable for 1 minute every time the pulling speed is increased by 0.1m / min until the normal pulling speed. Push in the special pouring powder when starting the casting, and set the vibration frequency of the crystallizer vibration table to 132Hz and the amplitude to 4.0mm when casting starts. The "red slag" operation is carried out in the tail out stage, and a small amount of water is sprinkled after the stopper is closed, and the time does not exceed 2 seconds.

Embodiment 3

[0041] This embodiment is to use the control method of the present invention to control the cracks of the head and tail blanks of high-strength steel Q690D.

[0042] Set the pre-flushing water 2 minutes ahead of the program before starting the pouring. After starting the pouring equipment, the casting speed will directly reach 0.4m / min, and then stabilize at 0.1m / min after 1min. 2 The acceleration is evenly increased, and the pulling speed is stable for 1 minute every time the pulling speed is increased by 0.1m / min until the normal pulling speed. Push in the special pouring powder when starting the casting, and set the vibration frequency of the crystallizer vibration table to 132Hz and the amplitude to 4.0mm when casting starts. The "red slag" operation is carried out in the tail out stage, and a small amount of water is sprinkled after the stopper is closed, and the time does not exceed 2 seconds. The head and tail blanks are arranged to be rolled into steel plates with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com