Special environment-friendly calcium hydroxide for tree protection and production method thereof

A technology of calcium hydroxide and production methods, applied in botany equipment and methods, chemicals for biological control, applications, etc., can solve the problem of high cost of bituminous coal logistics and transportation, achieve the effects of reducing heat pollution and improving liver function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

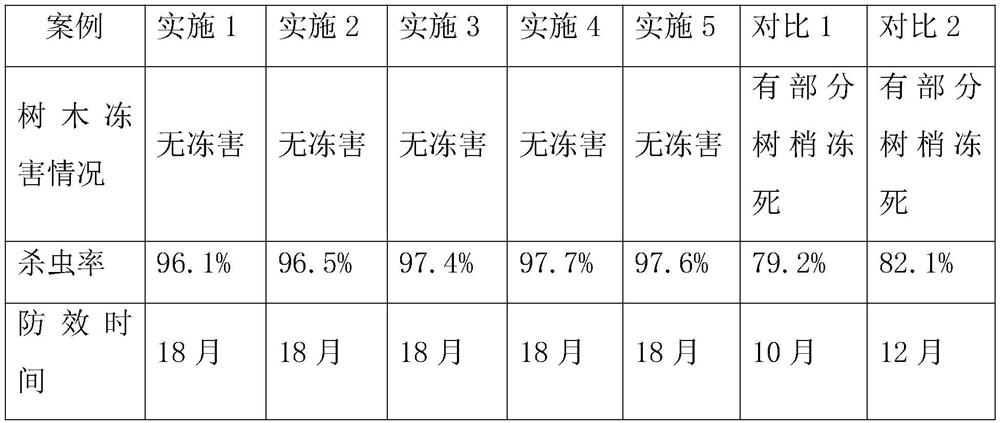

Examples

Embodiment 1

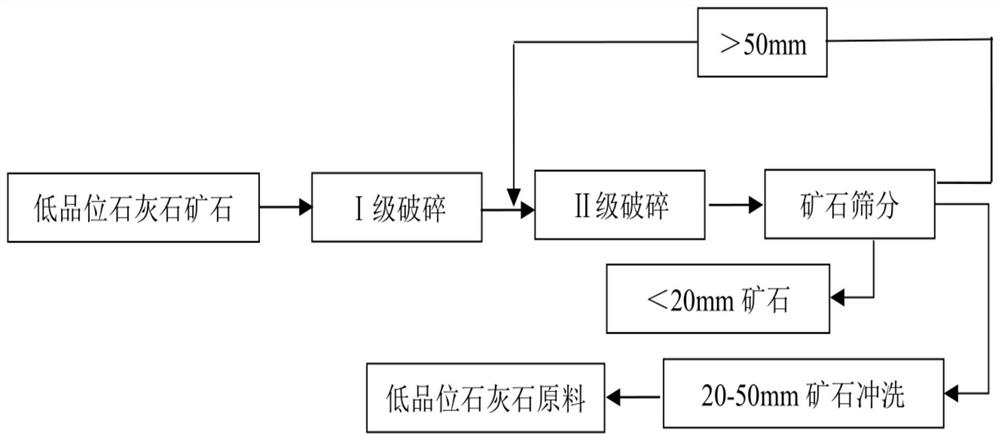

[0058] Step 1) Select low-grade limestone. The main components in the ore are: 44.0-52.0% calcium oxide, 5.0-12.0% magnesium oxide, 1.0-3.0% aluminum oxide, and 1.5-4.0% silicon dioxide in terms of oxide mass.

[0059] Step 2) Ore crushing, sieving, and washing: choose "two breaks and one sieve" to crush and sieve low-grade limestone ore, select 20mm ore for backup, and wash 20mm limestone ore to be used as raw material for quicklime production, wash The water supply pressure is 0.28MPa.

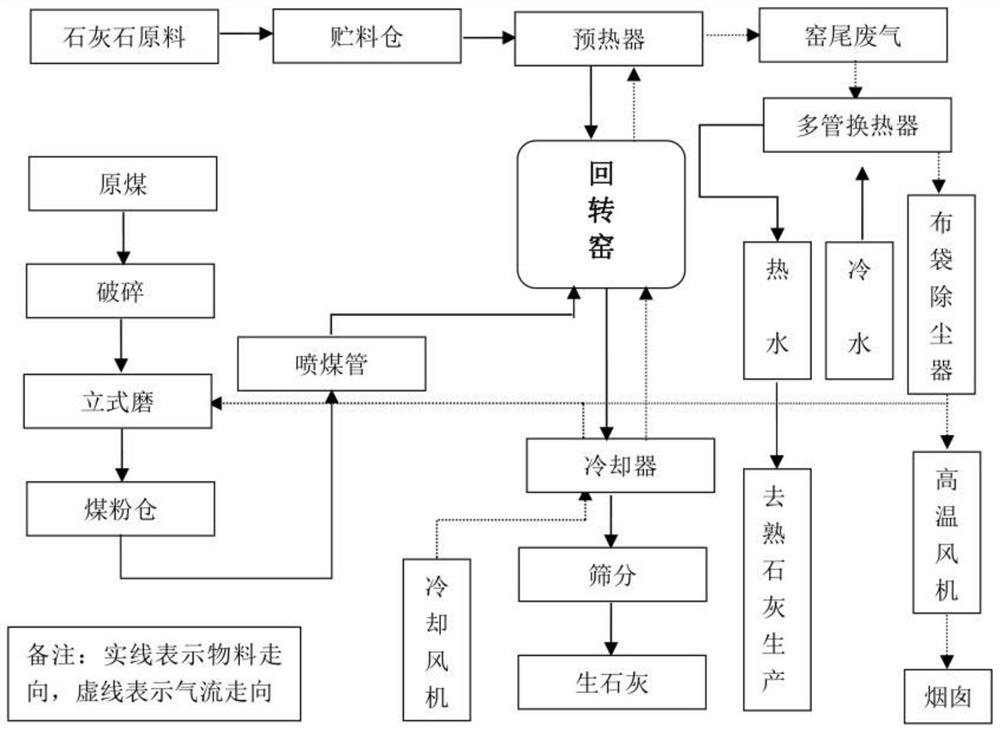

[0060] Step 3) selection of coal combustion and preparation of coal powder: coal combustion selects coal with calorific value 5000KCal / Kg, sulfur 1.5-2.0%, volatile matter 15.0-25.0%, ash content 20.0-25.0% southern local bituminous coal; vertical cooler is used Dry the coal with the waste heat of the exhaust gas (200-210°C) at the outlet of the vertical preheater to produce 180-mesh coal powder with a pass rate of 98.0% and a moisture content of less than 3.0%.

[0061] Step 4) Preheating ...

Embodiment 2

[0074] Step 1) Select low-grade limestone. The main components in the ore are: 44.0-52.0% calcium oxide, 5.0-12.0% magnesium oxide, 1.0-3.0% aluminum oxide, and 1.5-4.0% silicon dioxide in terms of oxide mass.

[0075] Step 2) Ore crushing, sieving, and washing: choose "two broken and one sieved" to crush and sieve low-grade limestone ore, select 50mm ore for backup, and wash 50mm limestone ore to be used as raw material for quicklime production, wash The water supply pressure is 0.30MPa.

[0076] Step 3) selection of coal combustion and preparation of coal powder: coal combustion selects coal with calorific value 5000KCal / Kg, sulfur 1.5-2.0%, volatile matter 15.0-25.0%, ash content 20.0-25.0% southern local bituminous coal; vertical cooler is used Dry the coal with the waste heat of the exhaust gas (200-210°C) at the outlet of the vertical preheater to produce 180-mesh coal powder with a pass rate of 99.0% and a moisture content of less than 3.0%.

[0077] Step 4) Preheating...

Embodiment 3

[0090] Step 1) Select low-grade limestone. The main components in the ore are: 44.0-52.0% calcium oxide, 5.0-12.0% magnesium oxide, 1.0-3.0% aluminum oxide, and 1.5-4.0% silicon dioxide in terms of oxide mass.

[0091] Step 2) Ore crushing, screening, and washing: choose "two breaking and one screening" to crush and screen low-grade limestone ore, select 30mm ore for backup, and wash 30mm limestone ore to be used as raw material for quicklime production, washing The water supply pressure is 0.29MPa.

[0092] Step 3) selection of coal combustion and preparation of coal powder: coal combustion selects coal with calorific value 5000KCal / Kg, sulfur 1.5-2.0%, volatile matter 15.0-25.0%, ash content 20.0-25.0% southern local bituminous coal; vertical cooler is used Dry the coal with the waste heat of the exhaust gas (200-210°C) at the outlet of the vertical preheater to produce 180-mesh coal powder with a pass rate of 99.0% and a moisture content of less than 3.0%.

[0093] Step 4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com