Flexible integrated electrochromic device and preparation method thereof

A technology of electrochromic devices and electrochromic layers, which is applied in the direction of instruments, nonlinear optics, electrolytic organic material coatings, etc., can solve the problems of complex structure and difficult integration, and achieve the effect of sensitive color change response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

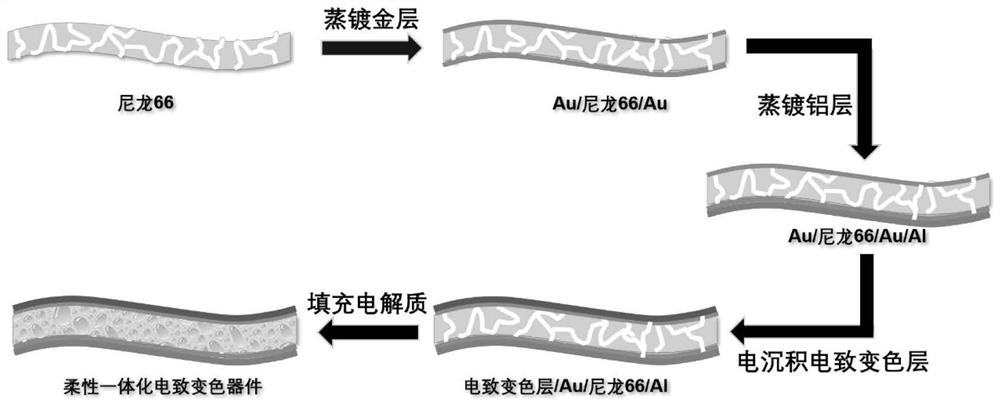

[0023] (1) The flexible nylon substrate is placed in the vacuum chamber of the thermal evaporation apparatus equipped with gold particles, vacuumed, and the vacuum degree is controlled at 2 × 10 -3 Pa; then, adjust the operating current to about 55A, and the deposition rate to be 5nm min -1 , conduct thermal evaporation for 20 minutes, and deposit a layer of gold with a thickness of about 100nm on both sides of the nylon substrate;

[0024] (2) Replace the gold particles with aluminum metal particles, vacuumize the thermal evaporation apparatus, and control the vacuum degree at 2×10 - 3 Pa; Then, adjust the operating current to about 60A, deposit an aluminum metal layer on the other side of the nylon substrate, and the deposition rate is 10nm min -1 , performing thermal evaporation for 5 minutes to obtain an aluminum metal layer with a thickness of about 50nm;

[0025] (3) Preparation of PANI electrochromic layer: the concentration is 1mol L -1 The sulfuric acid solution a...

Embodiment 2

[0029](1) The flexible nylon substrate is placed in the vacuum chamber of a thermal evaporation apparatus equipped with gold particles, vacuumed, and the vacuum degree is controlled at 2 × 10 -3 Pa, then, adjust the operating current to about 60A and the deposition rate to be 10nm min -1 , conduct thermal evaporation for 15 minutes; deposit a gold layer with a thickness of about 150nm on both sides of the nylon substrate;

[0030] (2) Replace the gold particles with aluminum metal particles, vacuumize the thermal evaporation apparatus, and control the vacuum degree at 2×10 - 3 Pa, then, adjust the operating current to be about 65A, and deposit an aluminum metal layer on the other side of the nylon substrate with a deposition rate of 15nm min -1 , performing thermal evaporation for 10 minutes to obtain an aluminum metal layer with a thickness of about 150nm;

[0031] (3) Preparation of PANI electrochromic layer: the concentration is 1.5mol L -1 sulfuric acid solution and 0....

Embodiment 3

[0035] (1) The flexible nylon substrate is placed in the vacuum chamber of a thermal evaporation apparatus equipped with gold particles, vacuumed, and the vacuum degree is controlled at 2 × 10 -3 Pa, then, adjust the operating current to about 65A, and the deposition rate to be 20nm min -1 , conduct thermal evaporation for 10 minutes, and deposit a gold layer with a thickness of about 200nm on both sides of the nylon substrate;

[0036] (2) Replace the gold particles with aluminum metal particles, vacuumize the thermal evaporation apparatus, and control the vacuum degree at 2×10 - 3 Pa, then, adjust the operating current to be about 70A, deposit an aluminum metal layer on one side of the nylon substrate, and the deposition rate is 20nmmin -1 , performing thermal evaporation for 10 minutes to obtain an aluminum metal layer with a thickness of about 200nm;

[0037] (3) Preparation of PANI electrochromic layer: the concentration is 2mol L -1 sulfuric acid solution and 0.5mol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com