XLPE cable sheath current on-line monitoring and fault diagnosis system

A fault diagnosis system and cable sheathing technology, applied in fault location, general control system, control/regulation system, etc., can solve the problems of inaccurate test model, test damage, high operation and maintenance cost, and achieve good technical economy, The effect of preventing power accidents and monitoring high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

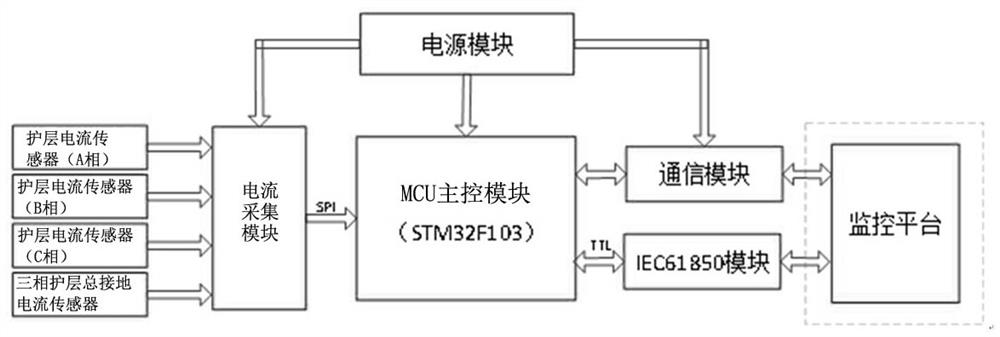

[0027] This embodiment discloses an on-line monitoring and fault diagnosis system for an XLPE cable sheath current, which is composed of a current sensor and an on-line monitoring device. The current sensor is installed on the grounding line of the cross-connection box of the tested cable. The current sensor and the online monitoring device are connected by a high-shielded coaxial cable. The online monitoring device can upload the monitoring results to the upper system platform in the form of a network port or an optical port. Different online monitoring devices can operate from the ring network. The devices have edge computing functions and built-in fault diagnosis algorithms to realize information processing, fault diagnosis and alarming on the spot.

[0028] Such as figure 1 As shown, the online monitoring device includes a current acquisition module, a communication module, a power module and an MCU main control module. The power supply module supplies power to the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com