Nano ecological floor heating system

An ecological and nano-technology, applied in the field of building structural materials, to achieve the effect of high-efficiency electrothermal conversion efficiency, smooth breathing, and high effective proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

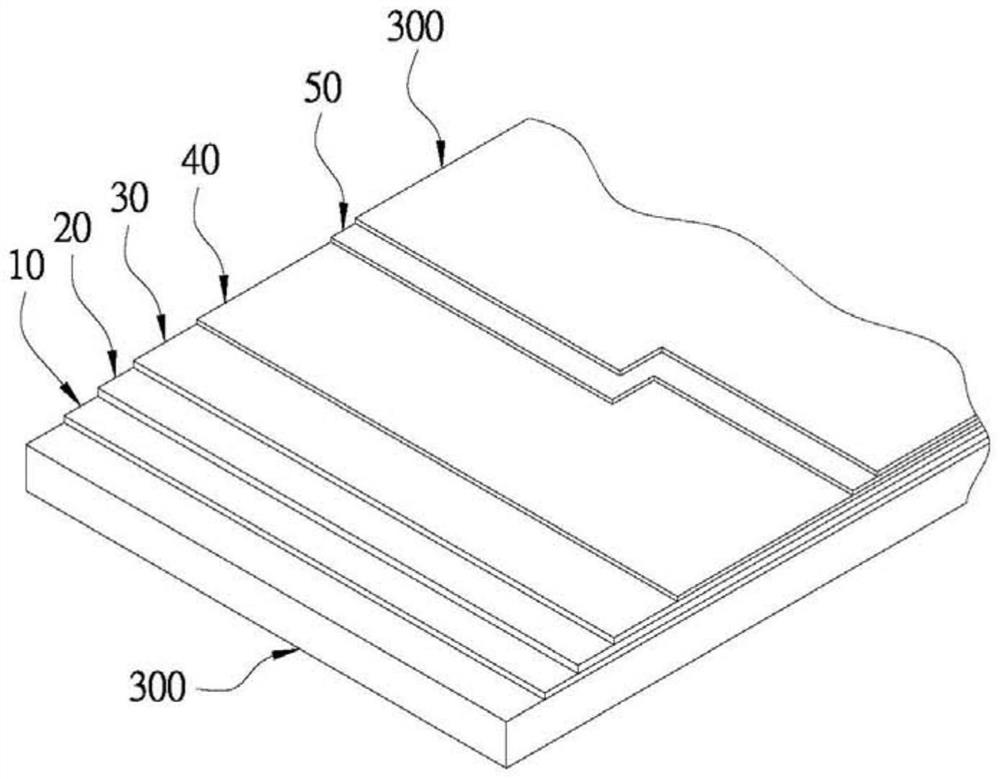

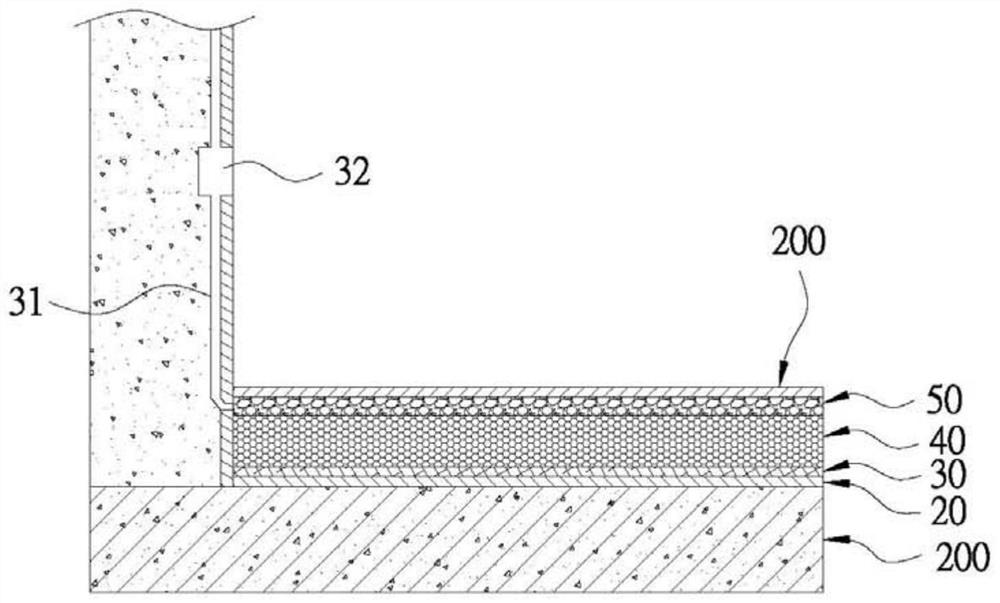

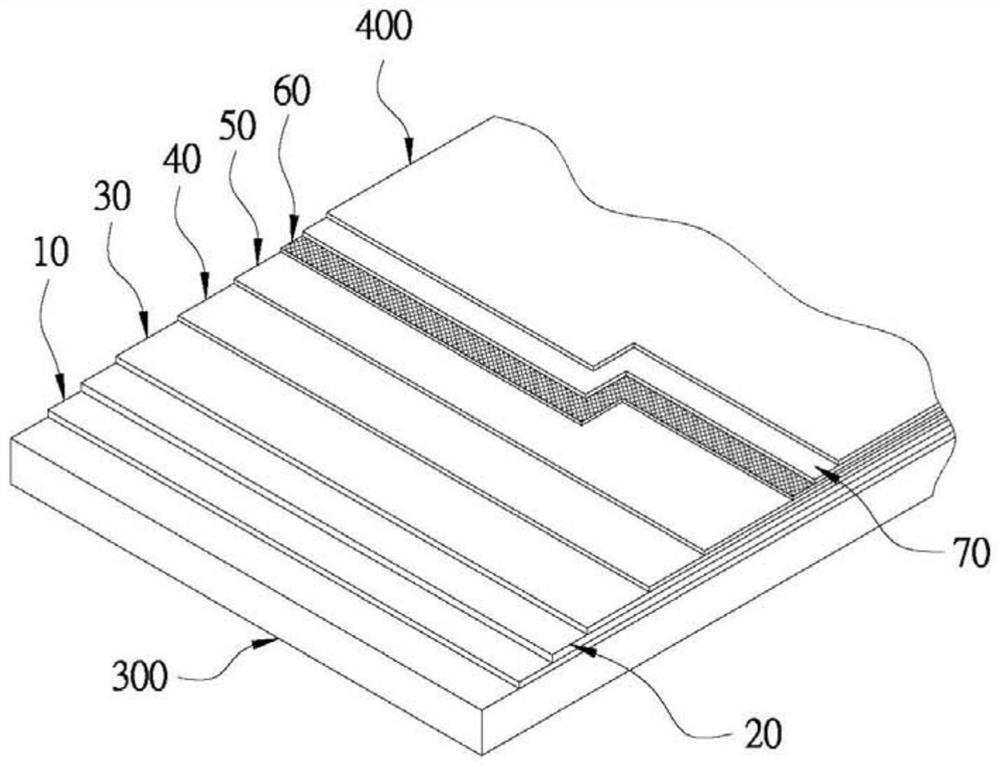

[0039] see figure 1 and figure 2 As shown, the construction structure schematic diagram of the overall structural schematic diagram of the nano-ecological floor heating of the present invention used in the dry paving process, which includes:

[0040] A reflective layer 10 is for laying on a cement floor 200. In this embodiment, the reflective layer 10 is made of an aluminum-plated reflective film with a thickness of about 0.5 cm.

[0041] A thermal insulation layer 20 is laid on the reflective layer 10. In this embodiment, the thermal insulation layer 20 is made of extruded plastic board with a thickness of about 0.2-0.5 cm.

[0042] A carbon nanotube electric heating film 30 is laid on the heat insulating layer 20. The carbon nanotube electric heating film 30 uses carbon nanotubes (Carbon Nanotube, CNT) as the heating core, and then is insulated and packaged to form an electric heating film. Its thickness is about 1 centimeter, the carbon nanotube electrothermal film 30 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com