Water stop device for starting slurry shield glass fiber enclosure structure

A glass fiber and enclosure structure technology, applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of easy cutting to the curtain, leakage of the door, failure of the water-stop structure, etc., and achieve the effect of saving manpower, material resources and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

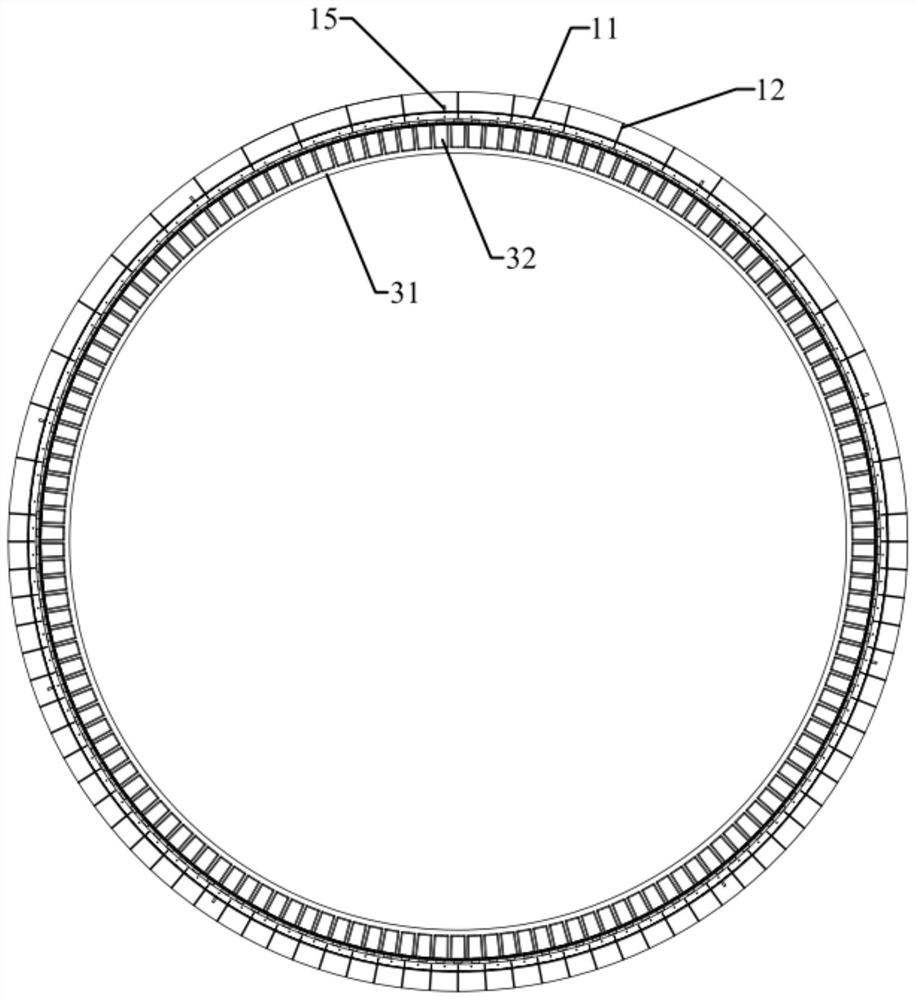

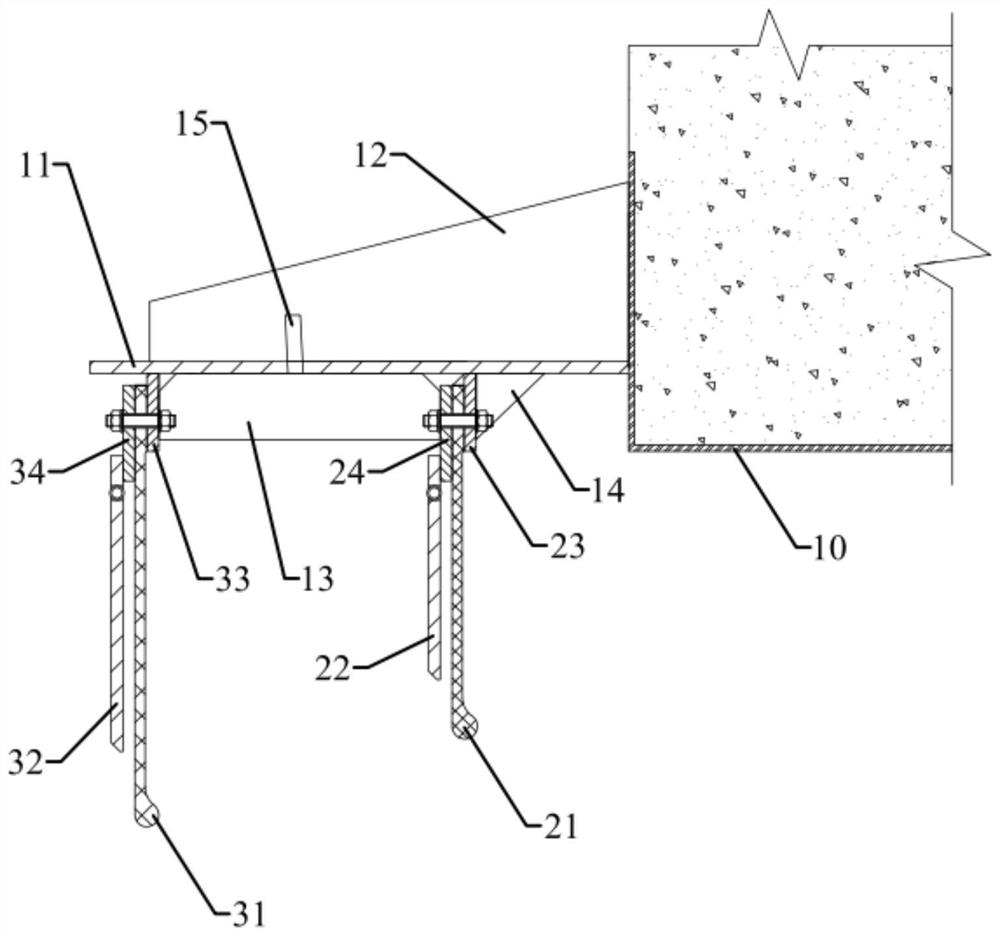

[0046] see figure 1 and figure 2 , The embodiment of the present invention provides a water-stop device for the initiation of mud-water shield glass fiber enclosure structure, including a box body 11, a first water-stop structure, a second water-stop structure and a sealing door structure.

[0047]The box body 11 is arranged on the outside of the hole, and one end of the box body 11 is fixedly connected with the steel ring 10 of the hole. Generally, a steel ring 10 is pre-embedded in the side wall of the shield well, and the steel ring 10 plays a certain supporting role. In this embodiment, the axis of the box 11 coincides with the axis of the steel ring 10. When the shield machine 30 starts, the starting axis of the shield machine 30 coincides with the axis of the box 11, that is, it starts along the straight line of the hole.

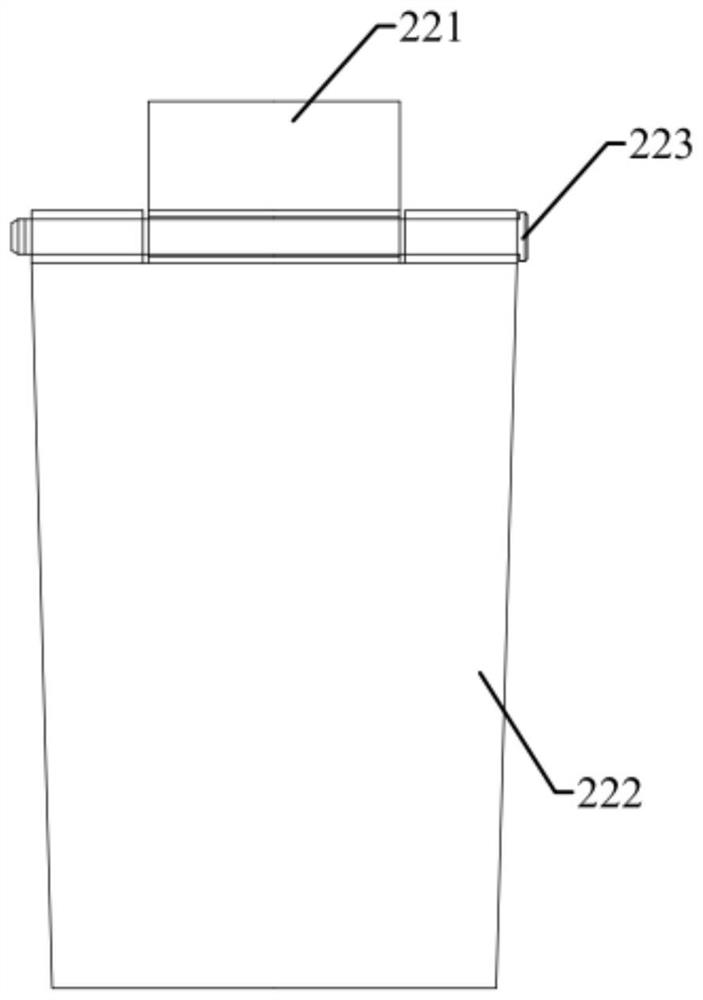

[0048] Both the first water stop structure and the second water stop structure are arranged inside the box body 11, the first water stop structure...

Embodiment 2

[0073] Figure 8 Embodiment 2 is shown, in which components identical or corresponding to those in Embodiment 1 are identified with reference numerals corresponding to Embodiment 1. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that the axis of the box 11 and the axis of the steel ring 10 are set at an angle. Since the starting axis of the shield machine 30 coincides with the axis of the box 11, the axis of the shield machine 30 and the steel ring There is an included angle between the axes of 10, the shield machine 30 starts along the curve, the shield machine 30 advances, passes through the box body 11 and the steel ring 10 and enters the hole in turn.

[0074] Wherein, the box body 11 can be welded by several arc plates during manufacture, and the width of the arc plates along the axial direction is gradually changed. In this embodiment, the box body 11 is welded by four arc plates.

[0075] By adjusting the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com