Single-pile foundation supported by inclined piles and construction method of single-pile foundation

A single pile foundation and inclined pile technology, which is applied in foundation structure engineering, sheet pile walls, non-rotational vibration suppression, etc., can solve the problem of high cost and risk of rock-socketed construction, the bearing capacity cannot meet the requirements, and the single pile foundation cannot be directly drilled. In order to achieve the effect of solving the insufficient bearing capacity of single piles, improving the integrity and coordination, and enhancing the comprehensive bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

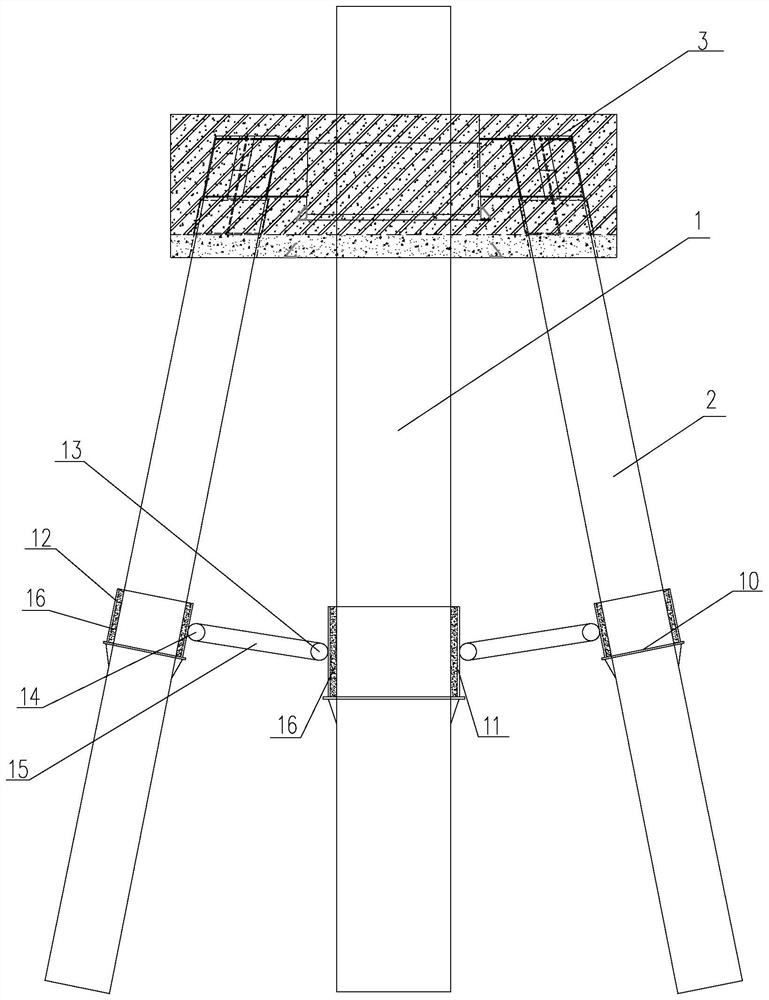

[0031] An offshore wind farm in the sea area of Fujian, my country, uses wind turbines with a single unit capacity of 7MW. The water depth of the site is 20-28m, the thickness of the site cover is 26-32m, and the bedrock geology is below the cover. If the single pile foundation or high pile cap foundation scheme is adopted, due to the thin cover layer, the bottom of the pile needs to be drilled into rock (embedded in moderately weathered rock). In addition, there is a high possibility of local weathered rock formations and boulders on site, and the risks of drill hole collapse and pile foundation driving into steel plate curling are prone to occur during on-site construction. Adopt the single-pile foundation (including support device) that uses inclined pile to support that the present invention proposes, then need not embed medium weathered rock, this scheme and its concrete implementation are as follows:

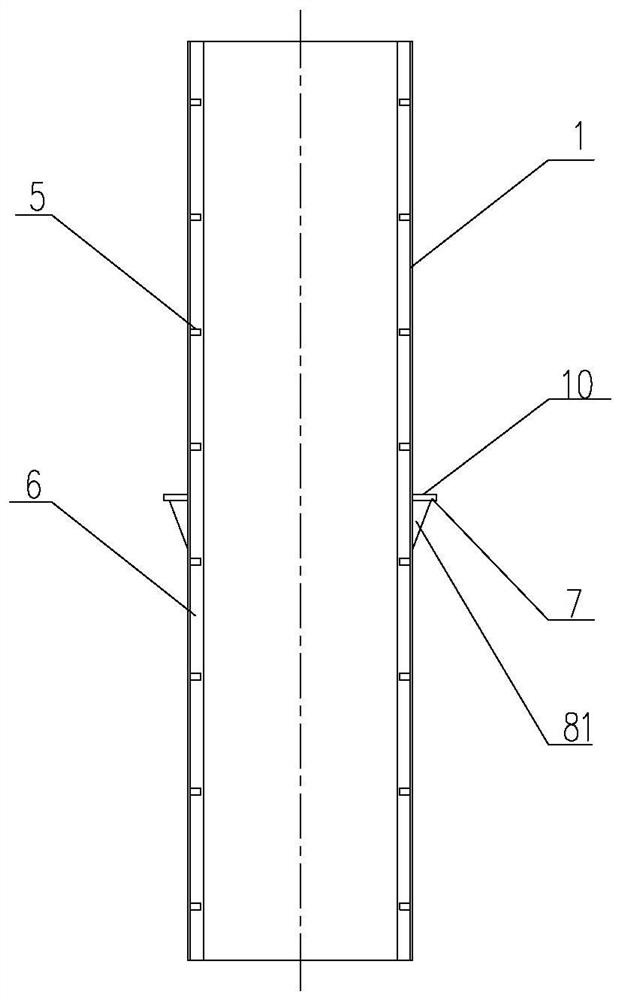

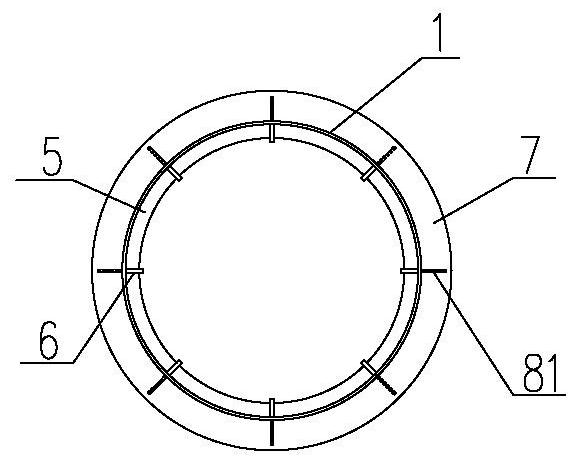

[0032] The large-diameter single pile 1 adopts steel pipe piles wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com