Construction method for reversed stepped special-shaped steel structure

A construction method and steel structure technology, applied in building structure, building material processing, construction, etc., can solve problems such as poor stability, complex structure, and floor damage, and achieve good stability, high safety, and fast installation and removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

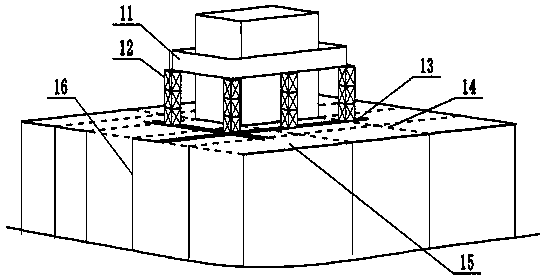

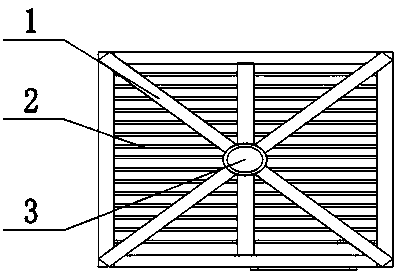

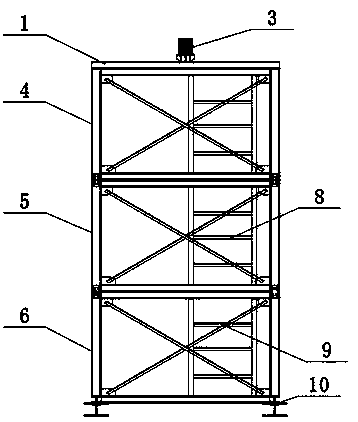

[0037] This embodiment: a construction method for an inverted stepped special-shaped steel structure, including a support system for supporting the construction of an inverted stepped special-shaped steel structure, see figure 2 with image 3 , including a supporting part, the supporting part is used to be arranged on the structural beam 14 of the lower building structure, the supporting part includes a bottom cross beam 13, and several supporting frames 12 are arranged on the bottom cross beam 13, and the supporting frame 12 includes a bottom section 6, a top section 4 and several middle segments 5, the bottom beam 13 includes two beam bodies arranged in parallel, and are respectively arranged opposite to the bottom segment 6, the bottom segment 6 is detachably connected to the beam body, and the bottom segment 6 is connected to the beam body They ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com