Post-grouting device for prestressed concrete pipe pile

A technology of concrete pipe piles and post-grouting, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering. Simple, eliminate the effect of external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

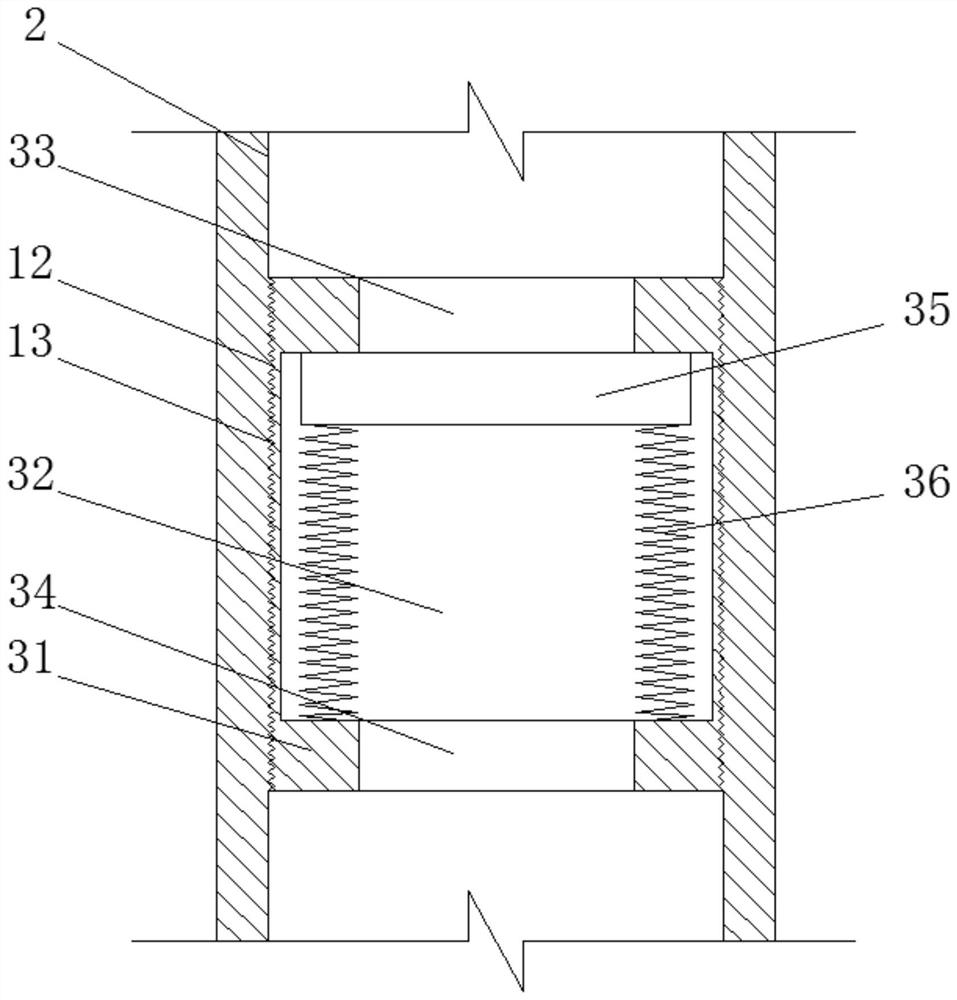

[0028] Example 1: Please refer to figure 1 , the present embodiment provides a post-grouting device for prestressed concrete pipe piles, including a grouting device body 1, and the grouting device body 1 is arranged in an inverted conical structure, so that the grouting device body 1 can be inserted into the soil layer easily, and at the same time , in order to ensure the structural strength of the grouter body 1, the grouter body 1 is made of reinforced concrete and then poured with concrete, and the strength grade should reach C30, so as to ensure that the grouter body 1 is not easy to break during work; The inside of the grouter body 1 is provided with a vertical main grouting channel 2, the top of the main grouting channel 2 passes out from the top surface of the grouter body 1, and the main grouting channel 2 passes from the grouter body 1 The outer wall of the pipe passing through the top surface is provided with a pipe clamp screw 7, which is used to facilitate the conn...

Embodiment 2

[0032] Since the grouting on the side of the pile and the grouting on the bottom of the pile are carried out at the same time in embodiment 1, there may be a problem that the amount of grouting is difficult to control. Based on this, embodiment 2 is proposed;

[0033] Example 2: Please refer to Figure 1~6 , this embodiment provides a post-grouting device for prestressed concrete pipe piles, including all the structures in Embodiment 1, and also includes the following structures: the middle part of the pile side grouting channel 5 and the middle part of the bottom of the main grouting channel 2 A variable diameter structure 10 is provided at the position where the bifurcation part is connected, and a steel ball 11 is also provided in the middle bifurcation part of the bottom of the main grouting channel 2. The diameter of the steel ball 11 is larger than the diameter of the variable diameter structure 10, so that the steel ball 11 can adjust the The structure 10 plays a blocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com