Preparation method of Co3O4/WO3/BiVO4 photo-anode

A photoanode and muffle furnace technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of weak surface kinetics, poor catalytic oxidation water cracking ability, high recombination rate of photogenerated carriers, etc., to achieve high efficiency Effects of water oxidation reaction, improvement of catalytic activity, enhancement of photoelectric stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

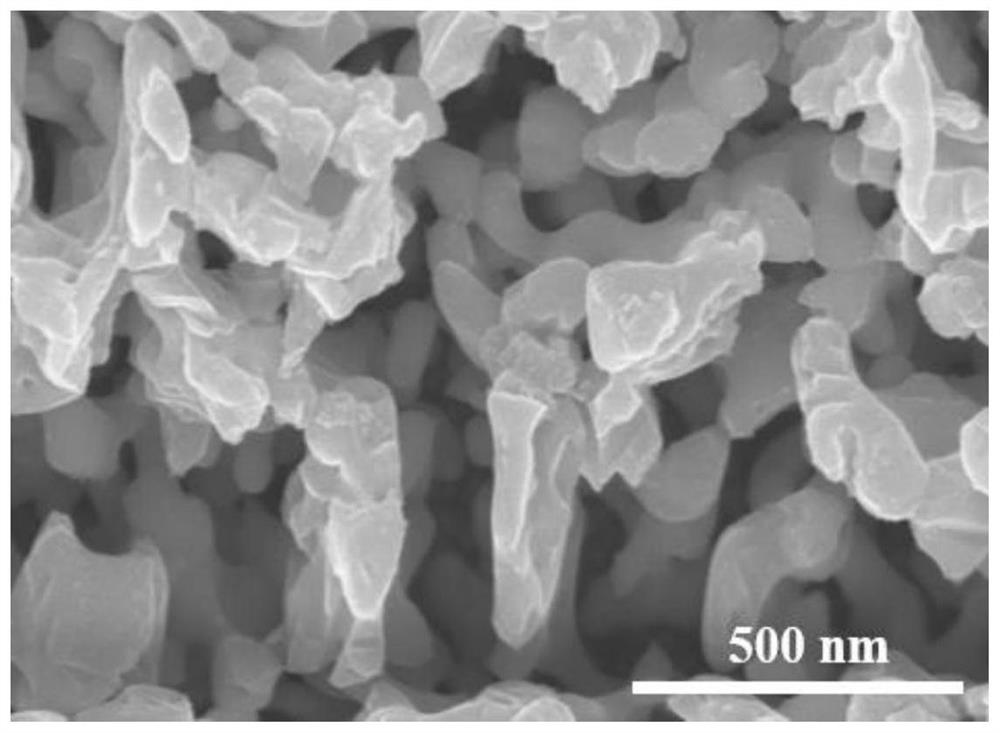

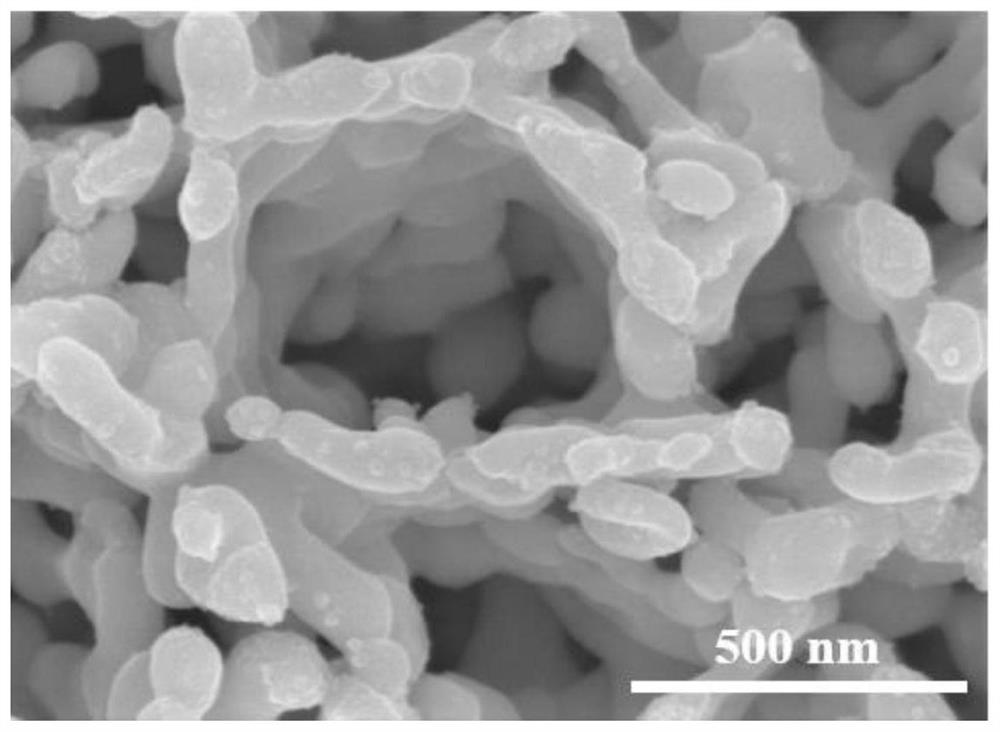

[0025] Example 1 One CO 3 O 4 / Wo 3 / BIVO 4 Preparation of light anode

[0026] 1) 9.963G Ki and 2.916G Bi (NO 3 ) 3 · 5h 2 O Slowly poured into 150 ml of pH = 1.7 nitric acid solution, stirred vigorously until completely dissolved until it gradually became an orange red solution, and 1.491 g was dissolved in 60 ml of benzoquinone in 60 ml of anhydrous ethanol, then mixed with orange red solution Ultrasound until the solution becomes dark red, that is, plating solution;

[0027] 2) Connect the electrochemical workstation CHI 660, the electroplated liquid surface of 1 cm × 2 cm FTO length is performed in the electroplated liquid surface as the working electrode, and the PT wire is the counter electrode, and the Ag / AGCL is the reference electrode, three The electrode system is -0.1vvs.ag / AGCl as input voltage, 300 seconds, made of thin and uniform BiOi glass sheet, weighing 0.106 g of acetylacetonate vanadium is dissolved in 1.0 ml of DMSO, mixed with mixing, 20.0 μl uniform dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com