Putty glue and preparation method thereof

A glue and putty technology, applied in the direction of adhesives, adhesive types, amide/imide polymer adhesives, etc., can solve the problems of formaldehyde residue in acetal glue, difficult process control of acrylamide, etc., and achieve poor polymerization stability. The effect of saving, changing the polymerization temperature rise and temperature control is difficult, and the production process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

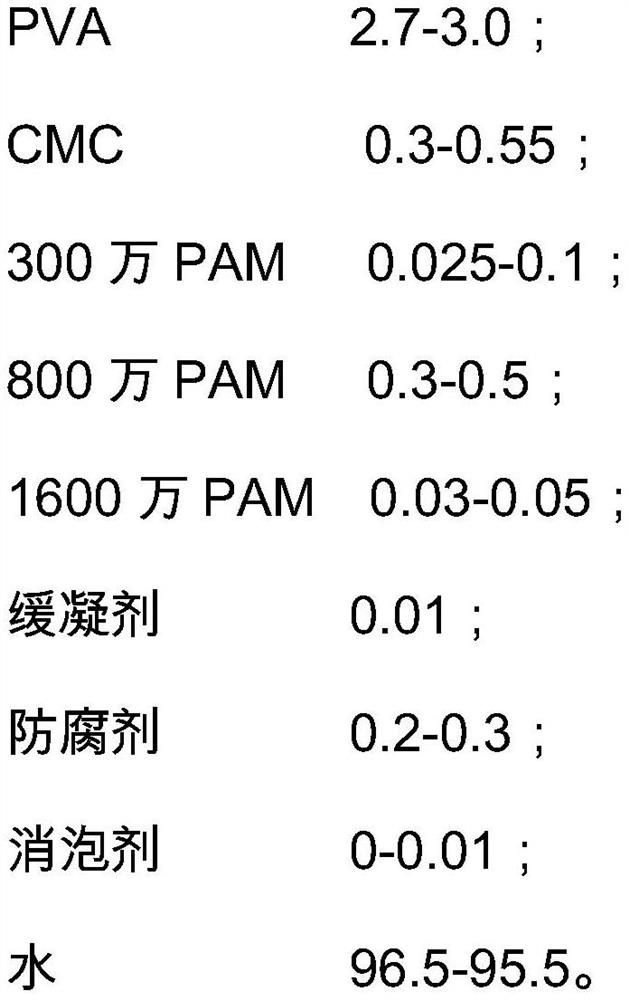

[0024] A kind of putty glue, is made up of each material of following mass parts:

[0025]

[0026] The mass ratio of glue to talcum powder is 1:1.33-1:2.1. For white cement plus talc 1:0.4:0.9-1:0.4:1.3

Embodiment 2

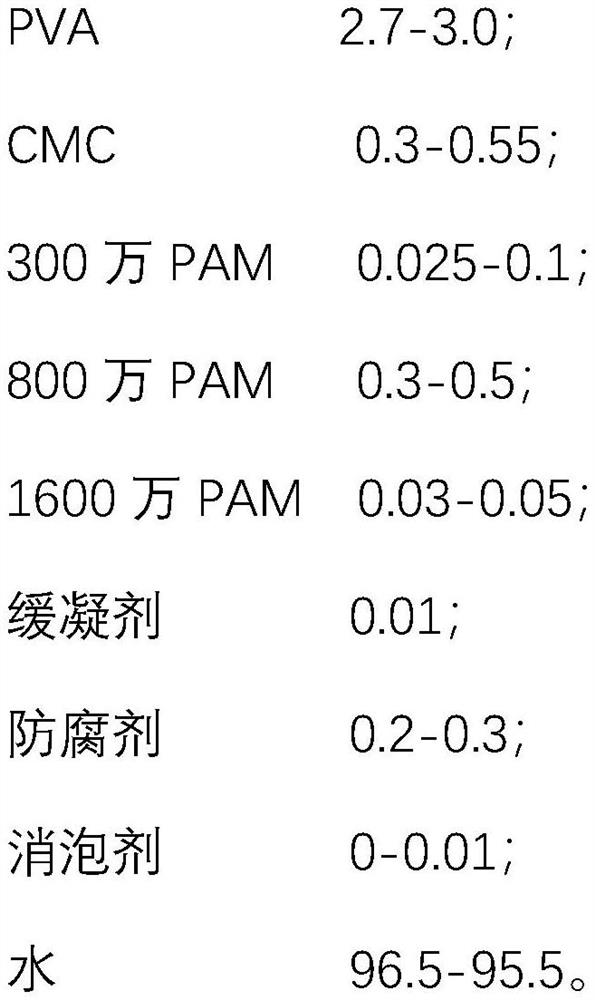

[0028] A kind of putty glue, is made up of each material of following mass parts:

[0029]

[0030]

[0031] The mass ratio of glue to talcum powder is 1:1.40-1:2.22; and that of white cement is 1:0.5:0.9-1:0.5:1.1.

Embodiment 3

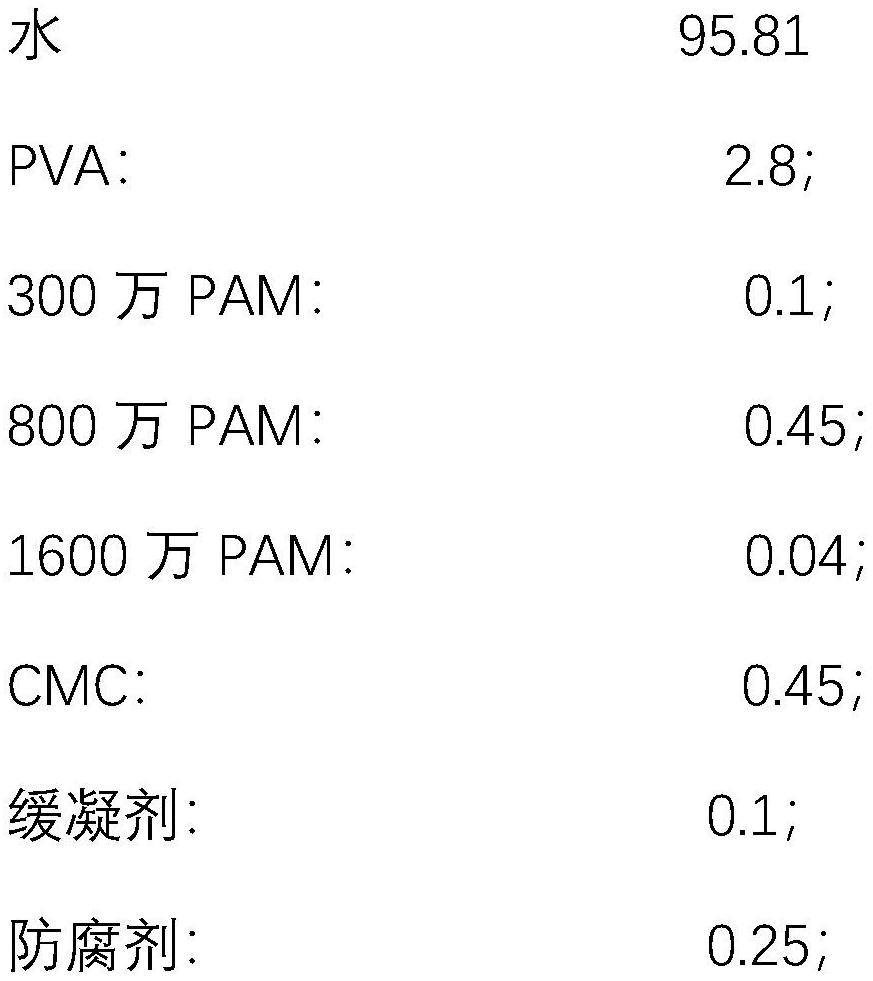

[0033] A kind of putty glue, is made up of each material of following mass parts:

[0034]

[0035] The mass ratio of glue to talcum powder is 1:1.38-1:1.96 to white cement 1:0.4:1.2-1:0.4:1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com