Nitrogen-containing nutritional biodegradable modified resin as well as preparation method and application thereof

A biodegradable resin and biodegradable technology, applied in the field of biodegradable resin modification, to achieve the effect of accelerating the degradation process, accelerating the degradation process and increasing crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

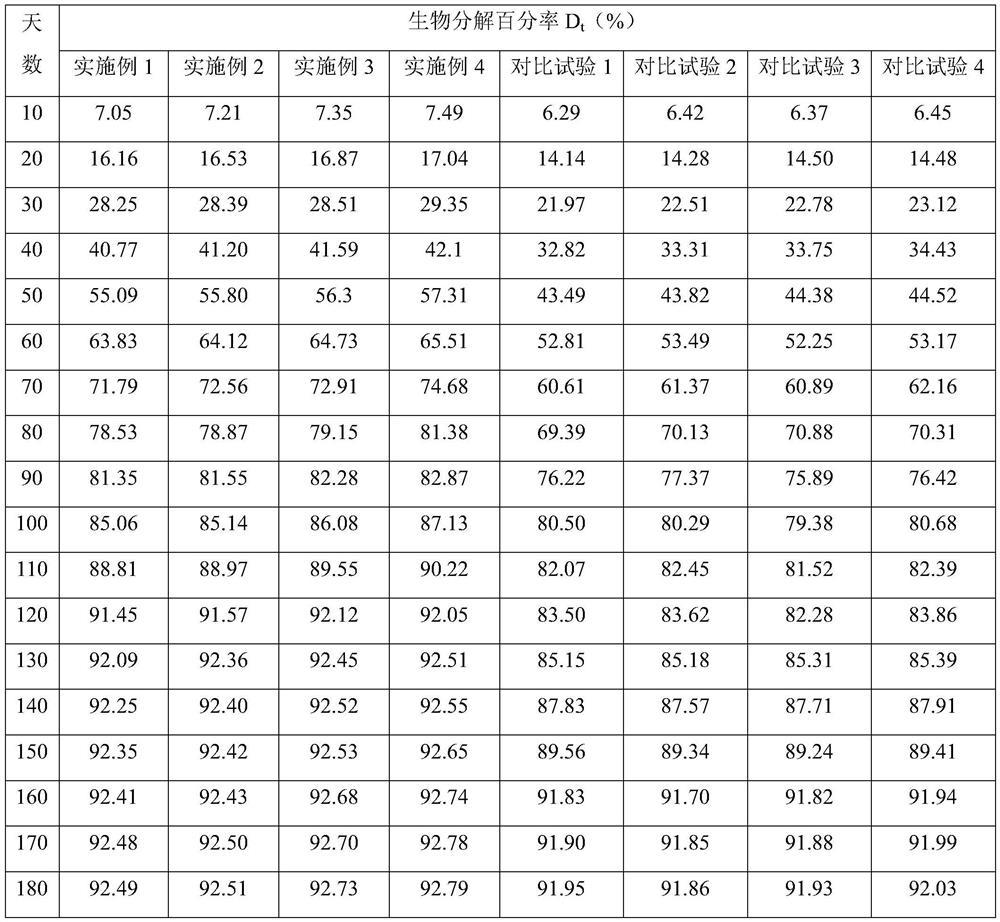

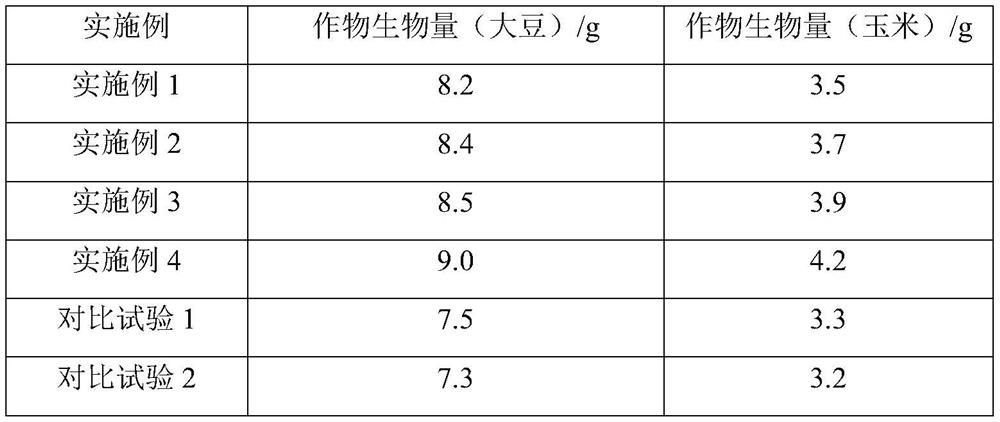

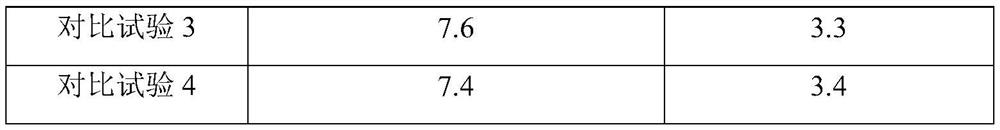

Examples

Embodiment 1

[0033] (1) Add 5 parts of oxalamide and 20 parts of talcum powder into the high-speed mixer, set the speed of the high-speed mixer to 500 rpm, preheat at 90°C for 10 minutes, and then add 0.5 parts of JL-G02FX type amino-terminated multi-component Alcohol ester coupling agent, and finally stirred at a high speed of 1000 rpm for 10 minutes to prepare an activated mixed powder.

[0034] (2) The mixed powder of 70 parts of PBAT, 5 parts of PLA, 0.3 part of antioxidant 1076, 0.2 part of antioxidant 626, 0.2 part of erucamide, 0.3 part of white oil and the activation treatment prepared by step (1) is fully After mixing evenly, put it into a parallel twin-screw extruder, set the temperature at 180°C, melt blend and air-cool and pelletize to prepare a biodegradable modified resin with adjustable degradation process.

Embodiment 2

[0036] (1) Add 10 parts of oxalamide and 15 parts of calcium carbonate into the high-speed mixer, set the speed of the high-speed mixer to 500rpm, preheat at 95°C for 8 minutes, and then add 1 part of SP-1082 hyperdispersive coupling agent , and finally stirred at a high speed of 1000 rpm for 10 minutes to prepare an activated mixed powder.

[0037] (2) The mixed powder of 70 parts of PBAT, 5 parts of PBS, 0.3 part of antioxidant 1076, 0.2 part of antioxidant 626, 0.2 part of erucamide, 0.3 part of white oil and the activation treatment prepared by step (1) is fully After mixing evenly, put it into a parallel twin-screw extruder, set the temperature at 160°C, melt blend and air-cool and pelletize to prepare a biodegradable modified resin with adjustable degradation process.

Embodiment 3

[0039] (1) Add 20 parts of oxalamide and 10 parts of calcium sulfate whiskers into the high-speed mixer, set the speed of the high-speed mixer to 500 rpm, preheat at 100°C for 5 minutes, and then add 2 parts of SP-1082 hyperdisperse couple Combined agent, and finally stirred at a high speed of 1000 rpm for 10 minutes to prepare an activated mixed powder.

[0040] (2) 60 parts of PBAT, 5 parts of PBS, 5 parts of PLA, 0.3 part of antioxidant 1076, 0.2 part of antioxidant 626, 0.2 part of erucamide, 0.3 part of white oil and the activation treatment prepared by step (1) The mixed powder was fully mixed and added into a parallel twin-screw extruder, set at 175°C, melted and blended, and air-cooled and pelletized to prepare a biodegradable modified resin with adjustable degradation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com