Tunnel lining double-trolley maintenance construction method suitable for alpine region

A construction method and technology in alpine areas, applied in the field of tunnel construction, can solve the problems of quality defects of secondary lining concrete, short steam curing time, limited steam curing time of concrete, etc., and achieve high construction efficiency, improve maintenance quality, and reduce construction equipment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

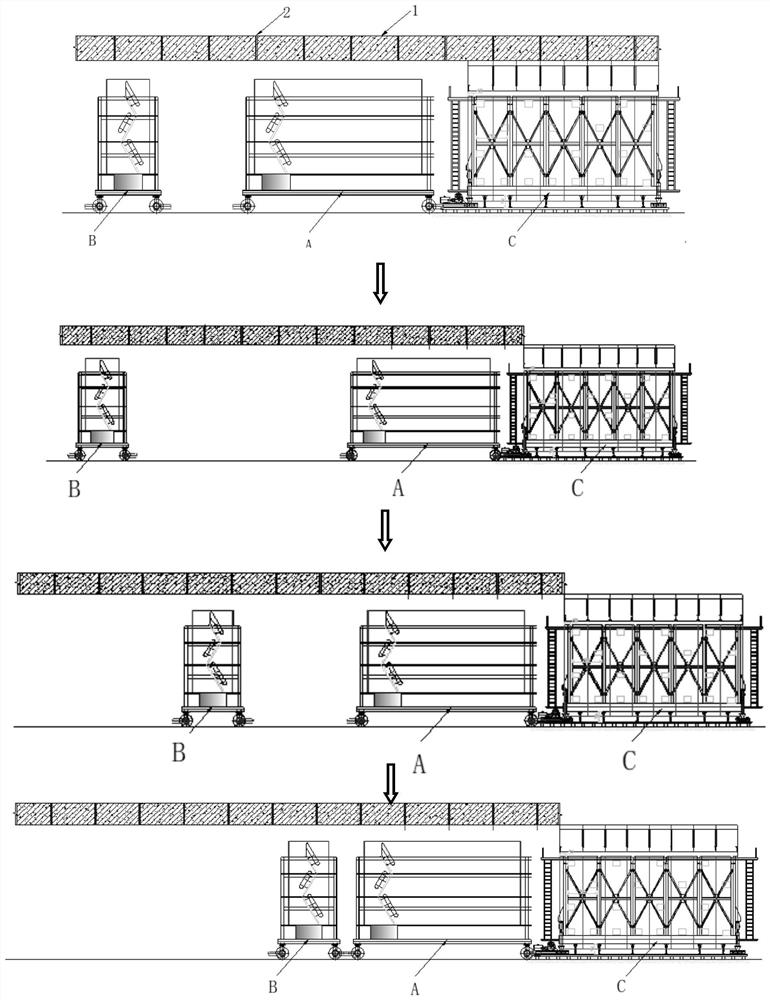

[0018] Such as figure 1 As shown, a tunnel lining double-trolley maintenance construction method suitable for alpine regions uses a tunnel lining double-trolley maintenance system for tunnel lining double-trolley maintenance construction.

[0019] The tunnel lining double-trolley maintenance system is mainly composed of constant temperature and humidity steam maintenance trolley A and round-trip spray follow-up maintenance trolley B.

[0020] Constant temperature and humidity steaming trolley A consists of constant humidity device, steaming water constant temperature device and telescopic temperature real-time monitoring device. The telescopic temperature real-time monitoring device is set on the top of the constant temperature and humidity steaming trolley, and can be inserted into the radial grouting hole 2 of the secondary lining 1 to measure temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com