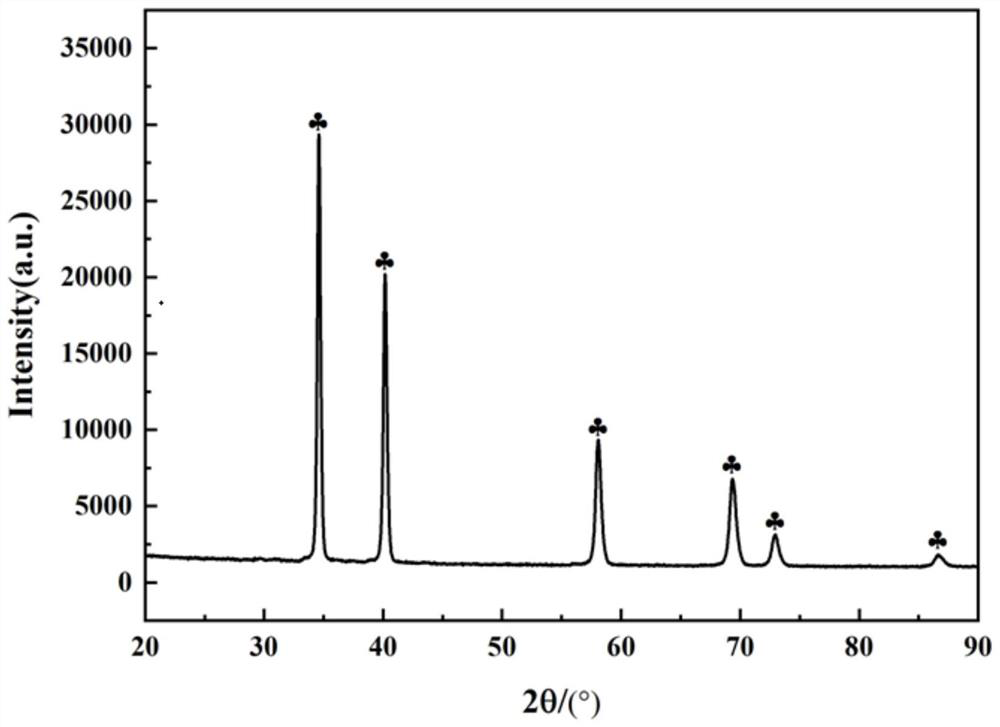

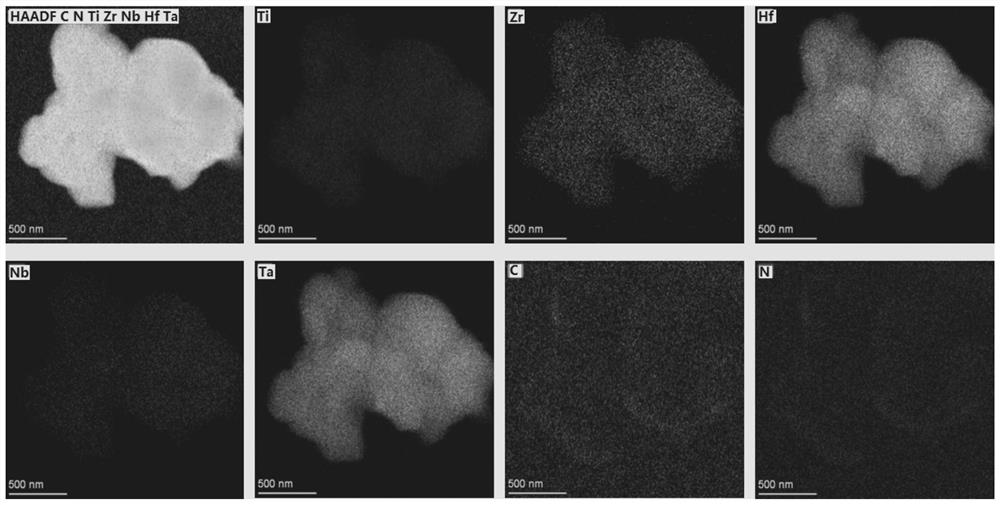

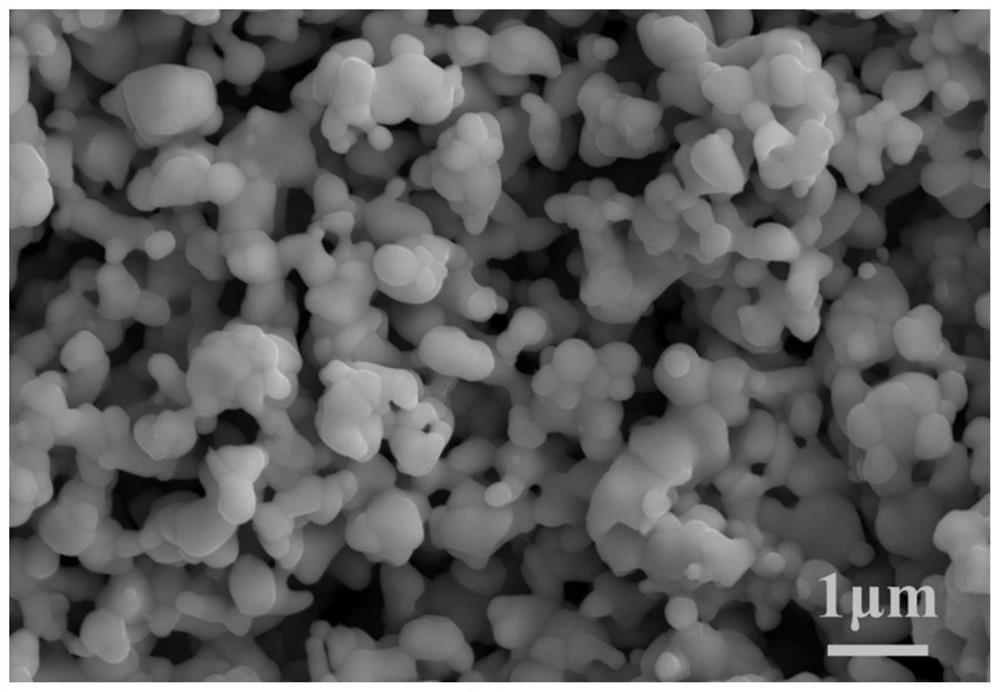

Synthesis method of (TiZrHfNbTa) CN high-entropy ultrahigh-temperature carbonitride ceramic powder

A carbonitride and ceramic powder technology, which is applied in the synthesis field of CN high-entropy and ultra-high temperature carbonitride ceramic powders, can solve the problems of easy introduction of oxides, high cost, impurities, etc., and achieves uniform composition distribution, low cost, and oxygen low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: a kind of synthetic method of (TiZrHfNbTa) CN high-entropy ultra-high temperature carbonitride ceramic powder in this embodiment is carried out according to the following steps:

[0019] 1. Prepare glucose mixed solution: mix glucose, water, acrylamide and N-N' methylenebisacrylamide, heat and stir to obtain glucose mixed solution;

[0020] 2. Preparation of oxide mixed powder: mix TiO 2 Powder, ZrO 2 Powder, HfO 2 Powder, Nb 2 o 5 Powder and Ta 2 o 5 The powder is mixed by ball milling to obtain an oxide mixed powder;

[0021] 3. Preparation of mixed slurry: adding the oxide mixed powder obtained in step 2 to the glucose mixed solution obtained in step 1, and dispersing by ball milling to obtain mixed slurry;

[0022] 4. Prepare gel: add triethanolamine and ammonium persulfate to the mixed slurry obtained in step 3, heat and stir to obtain gel, and then dry the gel;

[0023] 5. Gel heat treatment: place the dried gel obtained in step 4 ...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of glucose, water, acrylamide and N-N' methylenebisacrylamide in Step 1 is 100:100:40:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiments 1 and 2 in that: step 1 controls the heating and stirring temperature to 50-70° C. and the stirring time to 15-30 minutes. Others are the same as the first and second embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com