Mask transmission method

A transmission method and mask technology, which are applied in the field of control of the netting equipment, can solve the problems of dragging the time for transferring the screen to the screen frame, reducing the transport efficiency of the screen, and one-time handling of the clamping jaws, etc., which is beneficial to batch transmission. , The effect of reducing the transfer time to the workpiece table and overcoming the travel limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

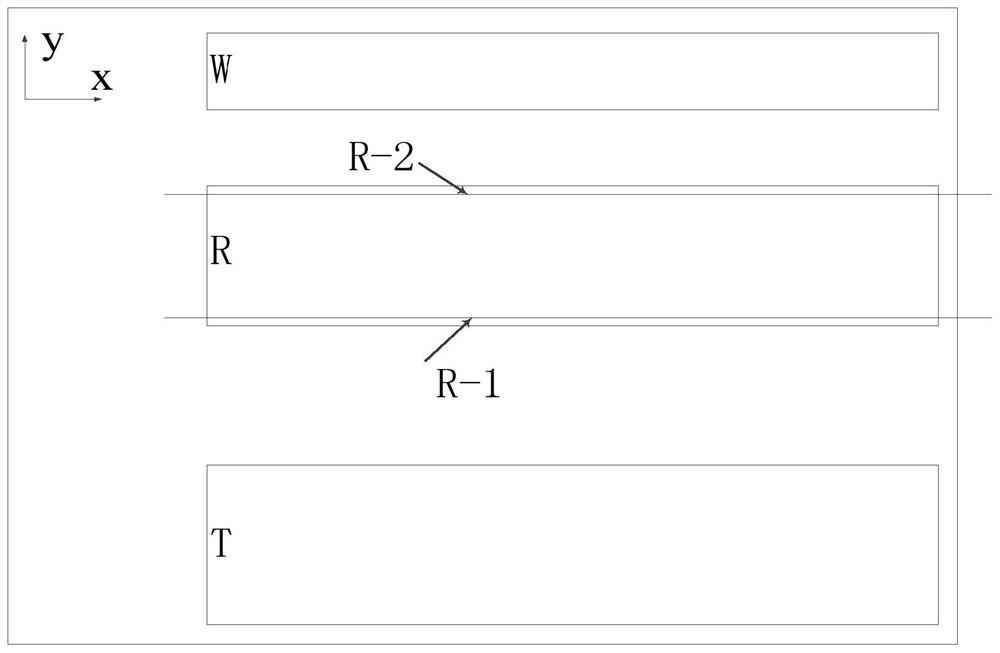

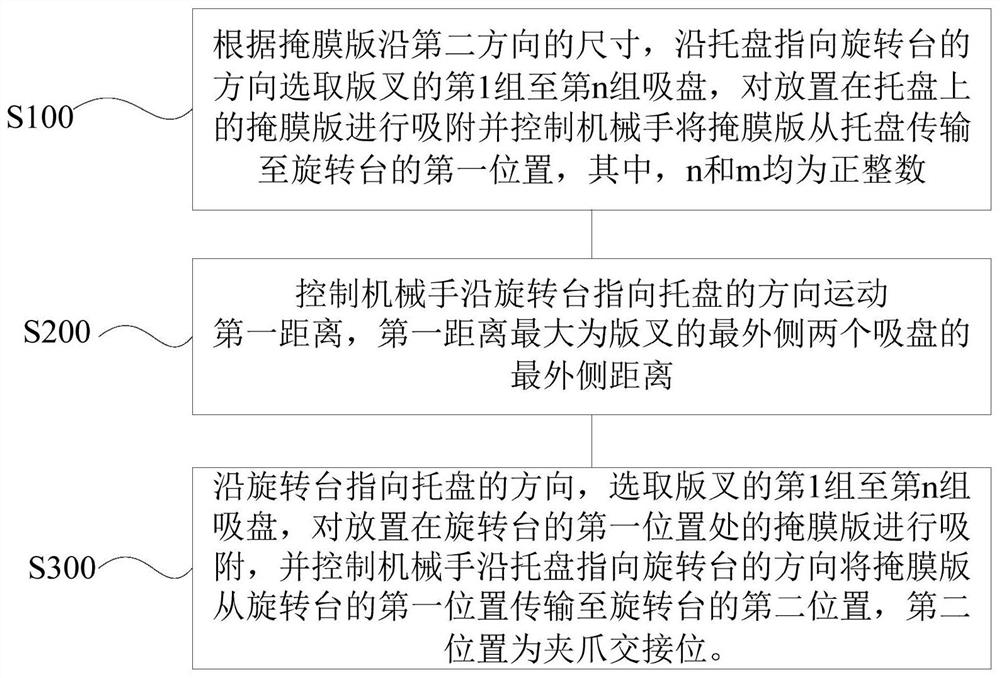

[0051] figure 2 It is a flowchart of a method for transferring a mask according to Embodiment 1 of the present invention. The method for transferring a mask is carried by a manipulator, and the manipulator includes at least two plate forks with a preset distance in the first direction; each plate The fork includes m groups of symmetrically distributed suction cups, each group of suction cups includes at least one suction cup, each suction cup is arranged at equal intervals along the second direction, and the first direction and the second direction are perpendicular; figure 2 As shown, the mask transfer method includes:

[0052] S100, according to the size of the mask plate along the second direction, select the first group to the nth group of suction cups of the plate fork along the direction of the tray pointing to the rotary table, to absorb the mask plate placed on the tray and control the manipulator to move the mask Plates are transported from the pallet to the first ...

Embodiment 2

[0064] This embodiment is a further refinement of the above-mentioned first embodiment. Optionally, according to the size of the mask plate along the second direction along the direction of the tray pointing to the turntable, select the first plate fork along the direction of the tray pointing to the turntable. The group to the nth group of suction cups absorb the mask plate placed on the tray and control the manipulator to transfer the mask plate from the tray to the first position of the rotary table, including:

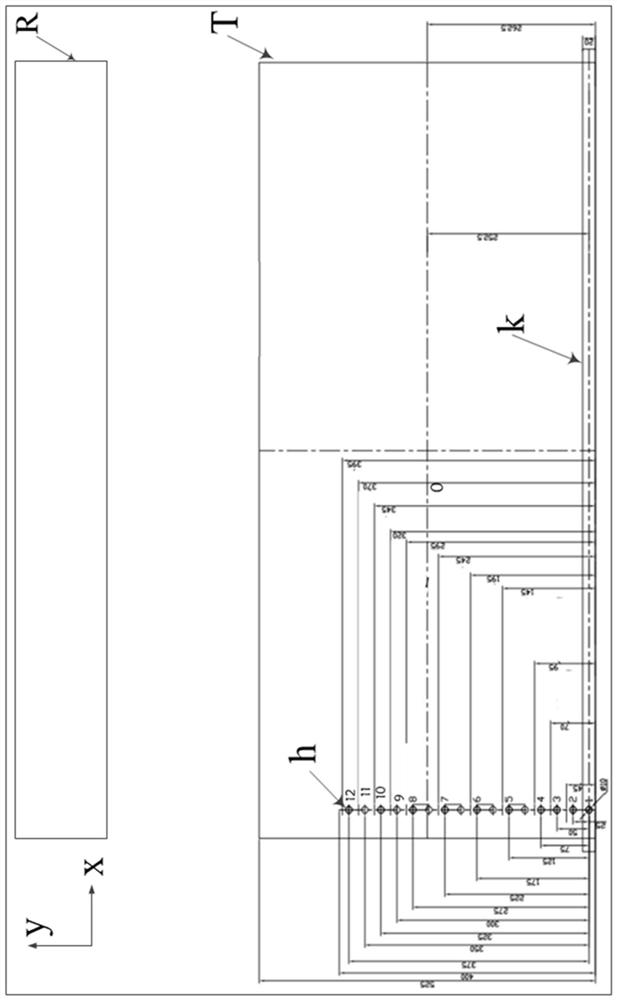

[0065] When the size B of the mask plate along the second direction is 1.5d≤B<(M+20), select the first group of suction cups along the direction of the tray pointing to the rotary table to absorb the mask plate placed on the tray, where d represents the diameter of the suction cup, M represents the center-to-center distance between the first group of suction cups and the second group of suction cups along the direction of the tray pointing to the turntable;

[0066...

Embodiment 3

[0079] This implementation is a further refinement of the first embodiment above. Optionally, according to the size of the mask plate along the second direction, along the direction of the tray pointing to the rotary table, select the first group to the nth group of suction cups of the plate fork, for The mask plate placed on the tray is adsorbed and the robot is controlled to transfer the mask plate from the tray to the first position of the rotary table, including:

[0080] According to the size of the mask plate along the second direction, determine the first group to the nth group of suction cups of the fork that absorbs the mask plate along the direction that the tray points to the rotary table;

[0081] Control the manipulator to run the second distance along the direction of the pallet pointing to the rotary table so that the center line of the outermost two suction cups in the first group to the nth group of suction cups along the direction of the pallet pointing to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com