Online health monitoring system and method for conveyor belt carrier roller based on resonance cavity wire spool

A health monitoring system and winding reel technology, applied in the direction of rollers, conveyors, conveyor objects, etc., can solve problems such as tearing, tape burning, tape breaking, etc., to reduce the impact of background noise and eliminate accumulated errors. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

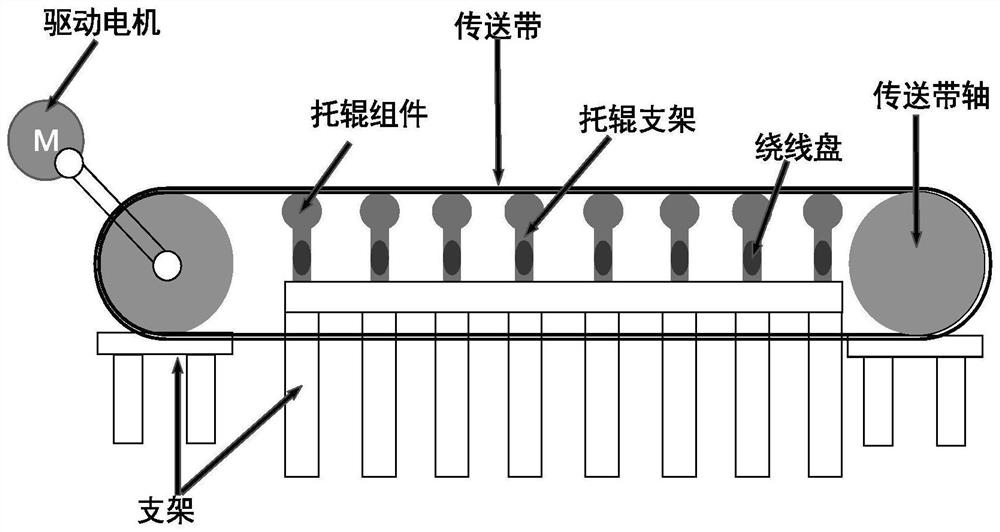

[0064] The embodiment of the present invention proposes an online health monitoring system for conveyor rollers based on resonant cavity winding reels. The monitoring system includes optical cables, distributed optical fiber vibration sensing systems and m winding reels with resonant cavity, where m is A positive integer greater than or equal to 2.

[0065] The m winding reels with resonance chambers are installed in the grooves of the m idler brackets one by one, the optical cables are tightly wound on the m resonating chamber winding reels in turn, and the optical cables wound on the winding reels lengthL 2 Cable length L between idlers corresponding to adjacent winding reels 1 The sum meets one or several spatial resolution requirements; the length of the optical cable before the first reel is (L 1 +L 2 )×n, n is a positive integer.

[0066] The distributed optical fiber vibration sensing system is connected to the end of the optical cable. When the conveyor belt stops ...

Embodiment 2

[0088] An embodiment of the present invention proposes an online health monitoring method for conveyor belt rollers based on a resonant cavity winding reel. The monitoring method includes the following steps:

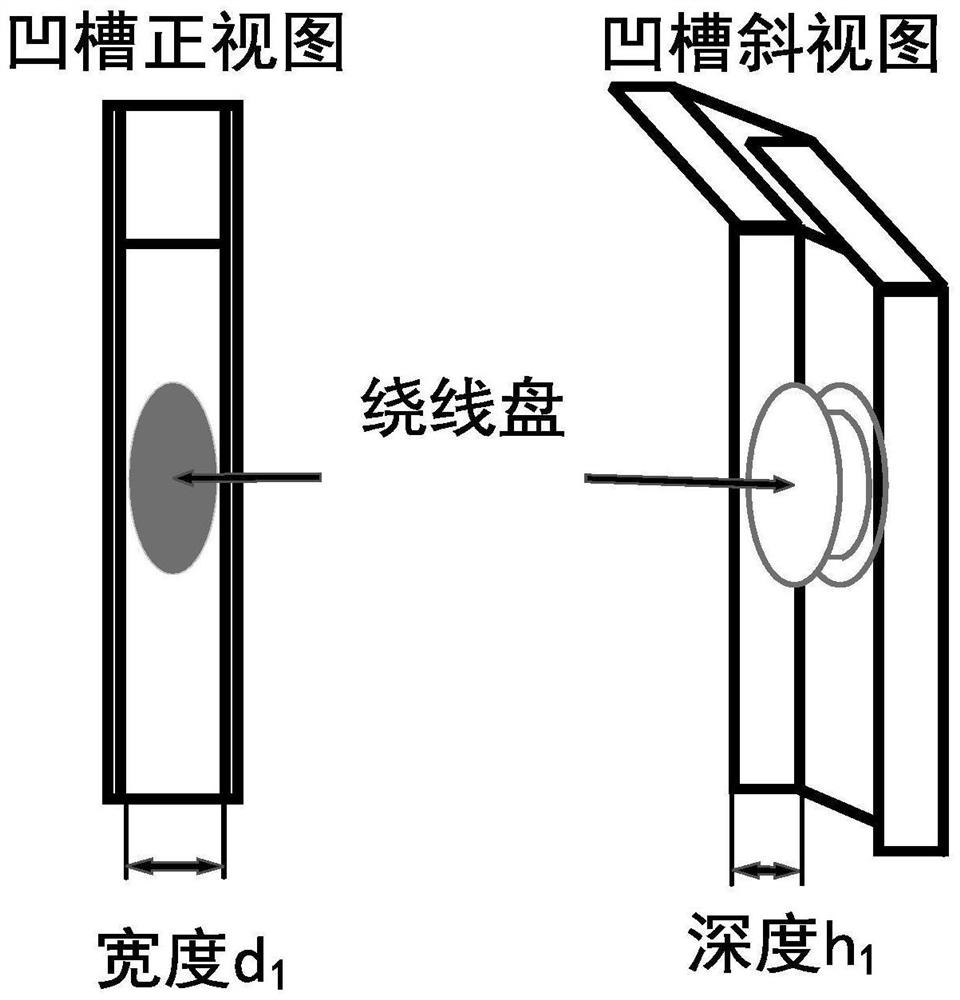

[0089] S1, measure the idler rollers of the conveyor belt to be monitored, and count the number of idler sets of the conveyor belt, the distance between the idler sets, the groove width and groove depth on the idler brackets.

[0090] S2, according to the parameters counted in step S1, fabricate the reel with resonance cavity as mentioned above.

[0091] S3, the optical cable is wound on the winding reel in turn, and then the winding reel is adsorbed in the groove of the idler bracket to be monitored one by one, and the optical cable is connected to the distributed optical fiber vibration sensing system.

[0092] S4, stop the conveyor belt, tap the rollers to be monitored one by one for 5 times, the distributed optical fiber vibration sensing system analyzes the collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com