High-reliability controller power supply system with subzero power consumption, method and storage medium

A technology of power supply system and control method, which is applied in the direction of general control system, control/regulation system, program control, etc., can solve the problems of complex interaction logic, low reliability of data power-off delay storage, increased sleep power consumption, etc., to achieve Achieve zero power consumption, stable and reliable control, and ensure the effect of data protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

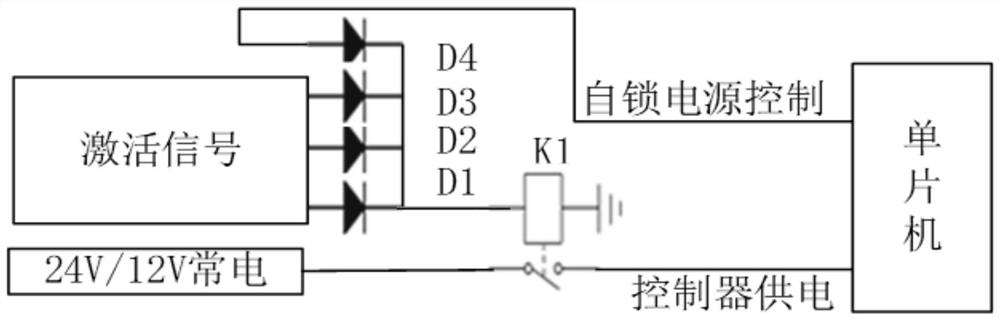

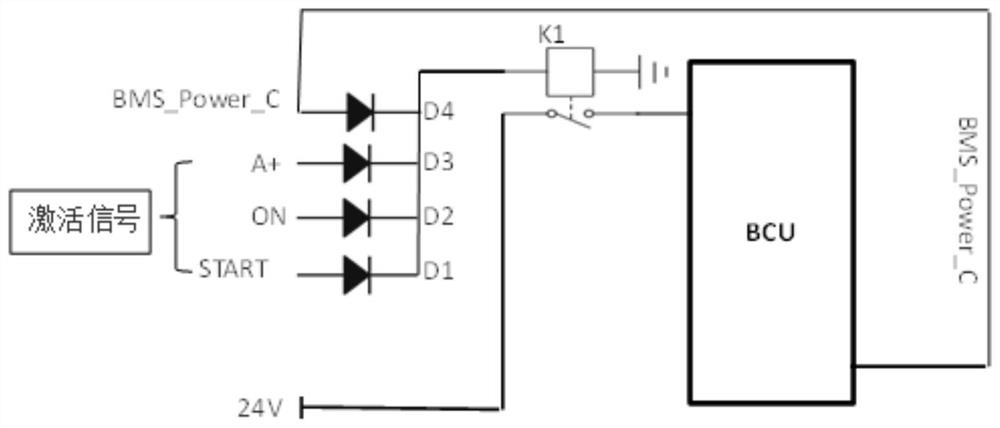

[0038] figure 2 Shows the preferred embodiment of the application ( figure 2 It shows a schematic structural diagram of a controller power supply system with high reliability and zero power consumption provided by the first embodiment of the present application). For the convenience of description, only the parts related to this embodiment are shown, and the details are as follows:

[0039] It includes the main control module BCU of the battery management system, the power supply relay K1, the first anti-series diode D4 and the second anti-series diode (D1, D2, D3), and the power supply relay K1 is connected to the normal power supply and the battery management system main Between the power signal input ends of the control module, the coil end of the power supply relay K1 is connected to the self-locking power control signal output end of the main control module of the battery management system through the first anti-series diode, and the coil end of the power supply relay K...

Embodiment 2

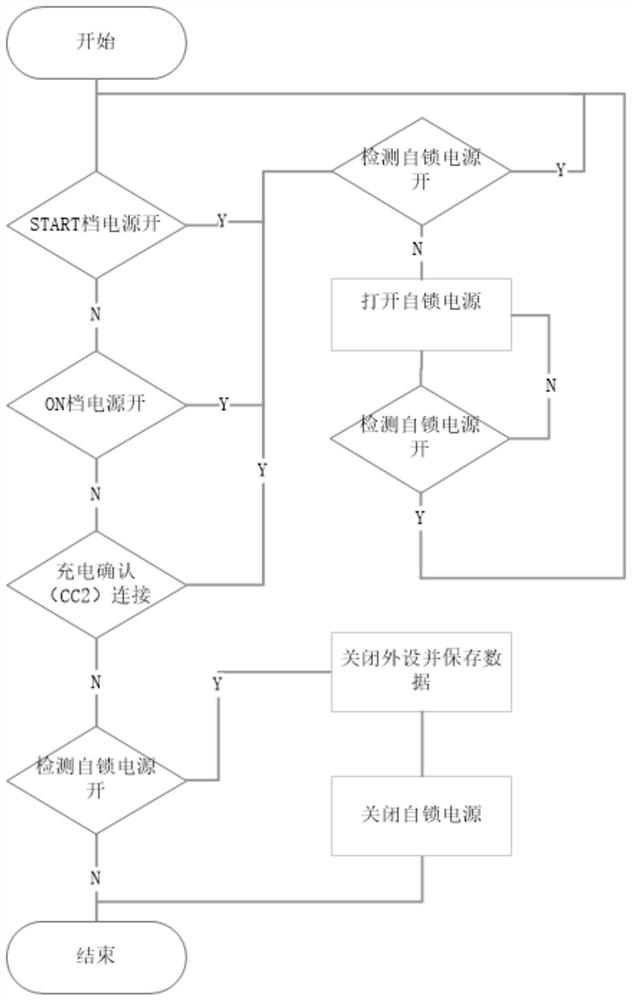

[0054] Such as image 3 Shown is a preferred embodiment of a controller power supply method with high reliability and zero power consumption, and its process is as follows:

[0055] Step 1, power on the BMS system.

[0056] Step 101: Turn the key switch to start the vehicle (START gear) or in the ON gear or plug in the national standard charging fast charging gun (that is, A+ has power input), that is, the front end of the hardware (D1 or D2 or D3) has power.

[0057] Step 102: After passing through the reverse series diodes (D1-D4), the coil of relay K1 is energized and closed.

[0058] Step 103: The single-chip microcomputer of the BCU module is powered on and starts to run.

[0059] Step 2, the power supply of the BMS system is self-locking.

[0060] Step 201: the single chip microcomputer executes the IO port initialization program.

[0061] Step 202: The single-chip microcomputer program outputs a high level to the power self-locking control port (ie, BMS_Power_C).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com