A kind of lithium tantalate crystal head and tail cutting method

A cutting method and lithium tantalate technology, applied in the field of piezoelectric crystals, can solve the problems of difficult to accurately fix the fixed glass sheet, prone to crystal orientation deviation, complicated operation process, etc., to avoid sliding, improve stability, and increase roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for cutting head and tail of lithium tantalate crystal, comprising the following steps:

[0032] (1) Crystal sandblasting fixed

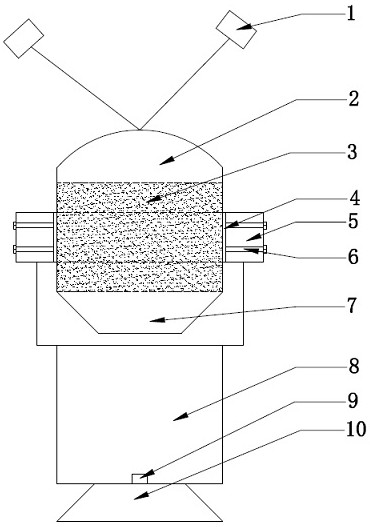

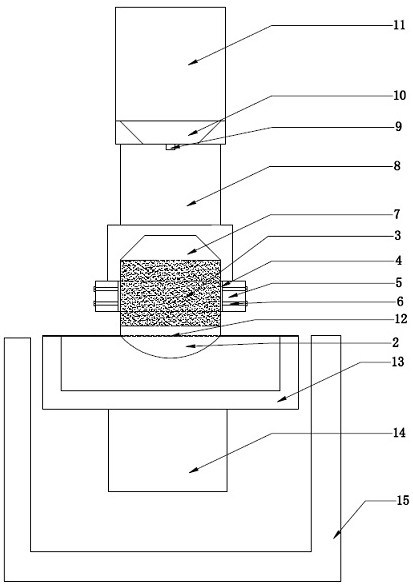

[0033] Scrub the surface of the lithium tantalate crystal with alcohol, fix it on a sandblasting machine, and use #50SiC sand for sandblasting at a frequency of 50Hz. like image 3 As shown in the figure, the sandblasted lithium tantalate crystal is fixed with a fixture, and the contact part between the fixture and the side of the crystal is buffered by a rubber sheet.

[0034] (2) Crystal orientation cutting

[0035] Use the orientation meter to turn on the X-ray to orient the crystal, such as figure 1 As shown, when determining the crystal orientation, use the spirit level on the bottom surface of the fixture to make the bottom surface of the fixture in a horizontal state, and adjust as follows: image 3 For the clamp screw shown, use the 4-direction 8-position fixed adjustment method to rotate the crystal to adjust the crystal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com