Cutting device for metal machining

A cutting device and metal processing technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of not having the position adjustment of cutting saws, inconvenient grinding of cutting objects, inconvenient waste guidance, etc., to achieve increased The effect of export speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

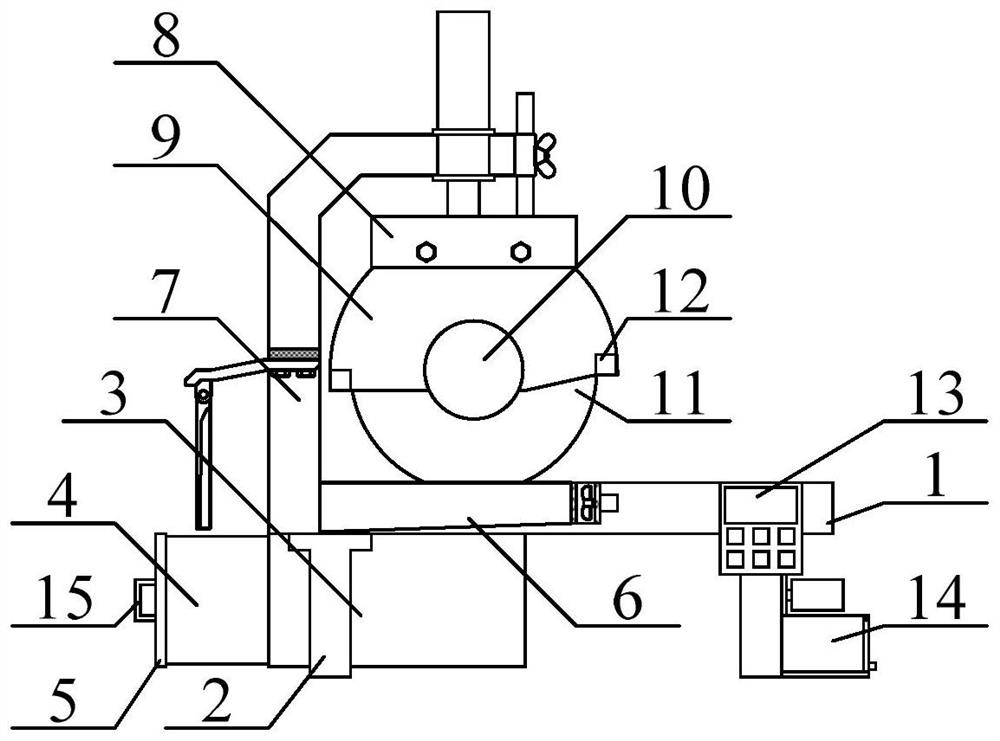

[0037] The present invention will be further described below in conjunction with the accompanying drawings:

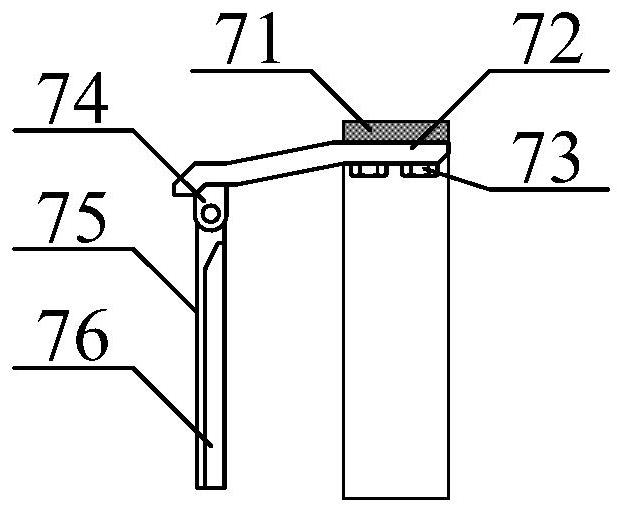

[0038] as attached figure 1 and attached image 3As shown, a cutting device for metal processing according to the present invention includes a worktable 1, a support frame 2, a storage insert frame 3, a storage bucket 4, a baffle 5, and a waste auxiliary guide frame structure 6, so that the waste can be removed. Guide frame structure 7, adjustable connecting frame structure 8, protective cover 9, cutting motor 10, cutting wheel 11, infrared sensor 12, control panel 13, auxiliary grinding frame structure 14 and handle 15, the support frame 2 is welded on The lower four corners of the workbench 1; the storage insert frame 3 bolts are installed on the lower left side of the workbench 1; the storage bucket 4 is inserted on the inner left side of the storage insert frame 3; the baffle 5 The screw is installed on the left side of the storage bucket 4; the waste auxiliary g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com