Method and system for performing ultraviolet ultrafast laser precise marking on titanium alloy surface

An ultrafast laser, titanium alloy technology, applied in the field of ultrafast ultrafast laser precision marking, can solve the problems of high cost and complicated procedures, and achieve the effect of good quality, accurate timing matching and good processing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

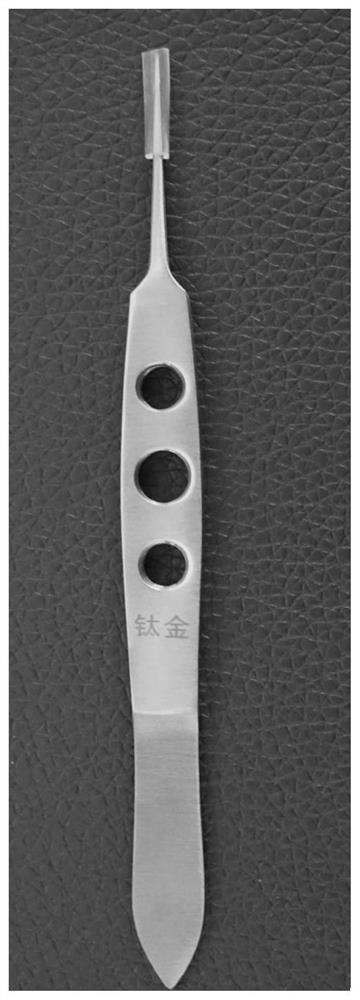

[0068] Example 1: Precise marking of "titanium gold" pattern on the surface of titanium alloy scalpel

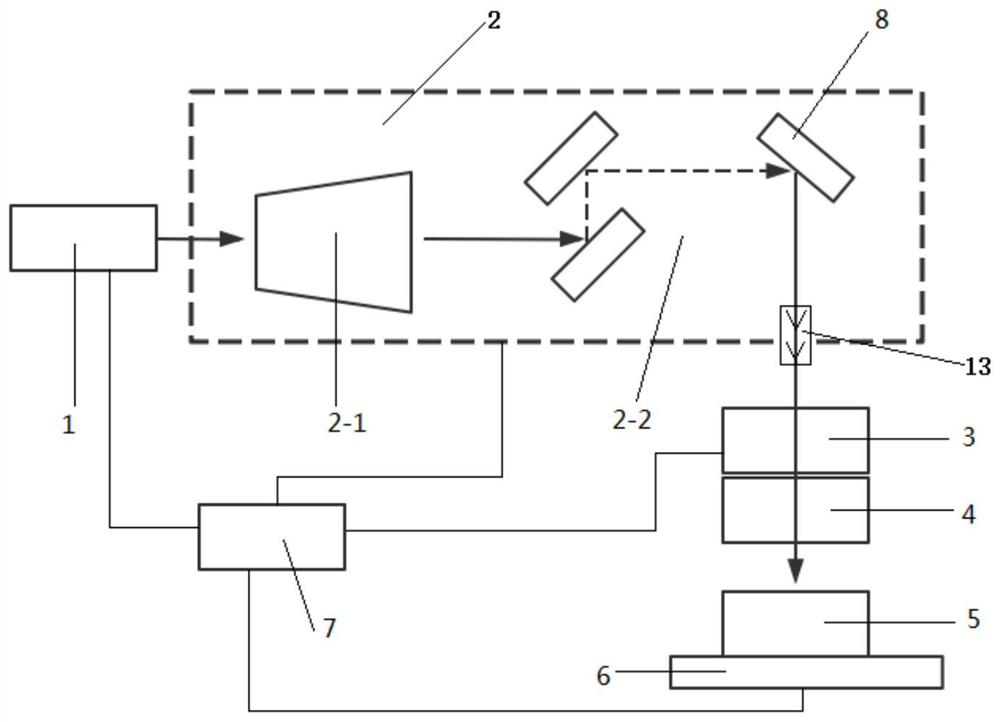

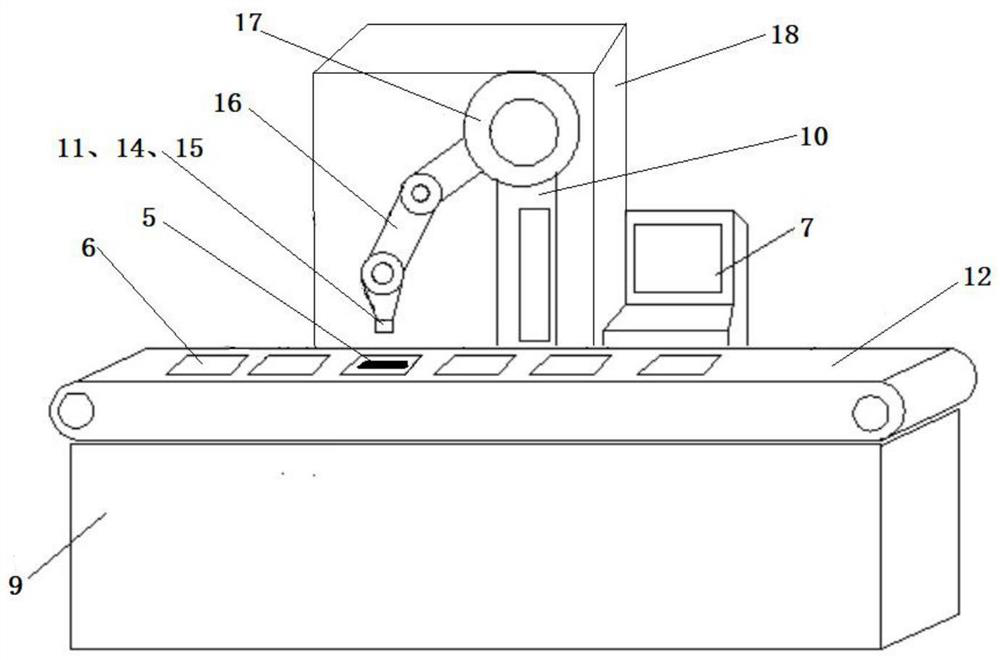

[0069] The laser is connected to the computer installed with the laser marking system software through the data line, and the computer inputs the controlled laser power, scanning speed, repetition frequency and other signals to the laser, and the laser is an all-solid-state picosecond laser. The controller receives the pulse synchronization signal of the laser, and at the same time controls the laser optical system 10 and the driving mechanism of the conveyor belt 12 to complete the marking.

[0070] The emission frequency of the locking laser is 100KHz, and the single pulse energy is 200uJ;

[0071] The single pulse is a single pulse photon spike wave, and the single pulse width is 10ps.

[0072] Laser wavelength is 355±5nm.

[0073] The laser window spot is 1mm, and the divergence angle is 1mrad.

[0074] The shaping optical path is a beam expanding optical path with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com