An automatic casting device and casting method for valve body production and manufacturing

An automatic, valve body technology, applied in manufacturing tools, casting equipment, casting melt containers, etc., to achieve the effect of low construction cost, high casting quality and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

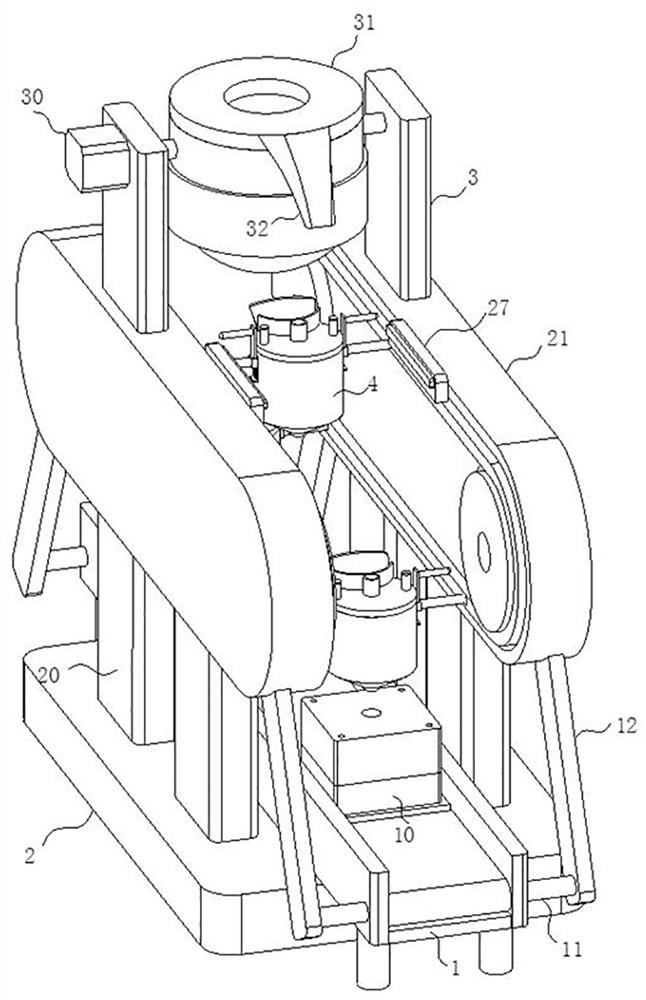

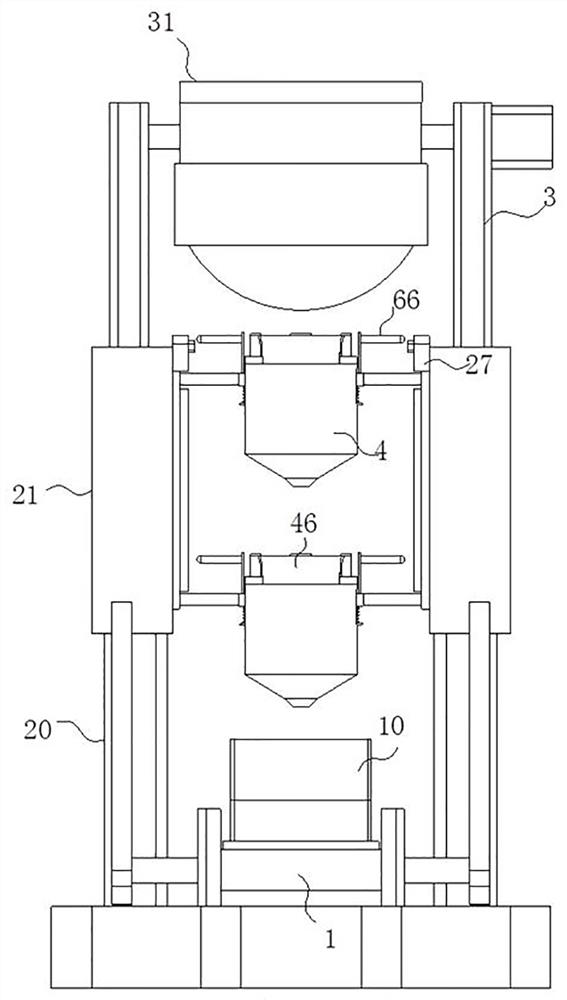

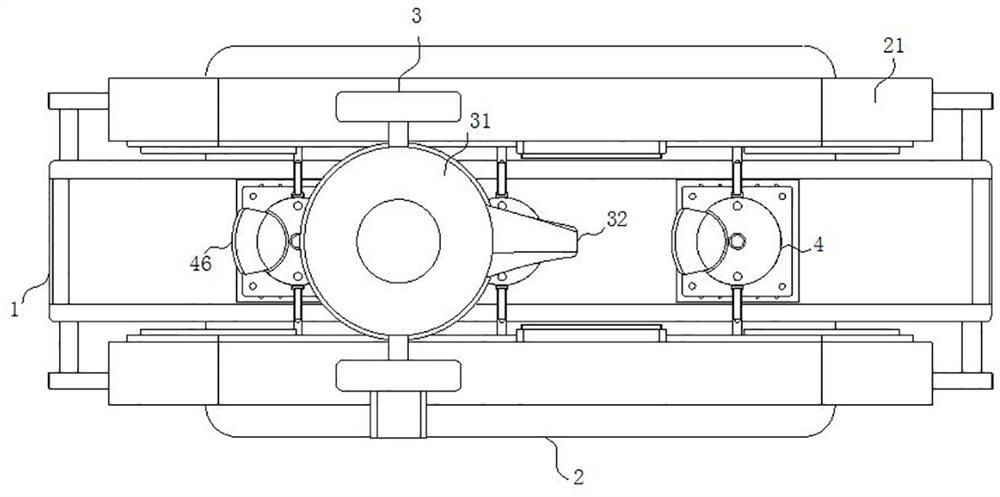

[0039] see Figure 1-14 , the present invention provides a technical solution: including a conveying table 1 for conveying the casting mold 10, a bottom pouring cylinder 4 for injecting molten iron into the casting port of the casting mold 10, and a main pouring cylinder for replenishing the bottom casting cylinder 4. package 31;

[0040] Just above the conveying table 1, there is a synchronous conveying part for conveying the bottom injection and transfer cylinder 4, and a plurality of bottom injection and transfer cylinders 4 are arranged on the synchronous conveying part. There are two travel racks 21, each travel rack 21 is provided with an annular travel belt 23 that is actively rotating and in a vertical state, and each bottom injection transfer cylinder 4 is erected between the two travel belts 23 by the bracket rods 62 on both sides of the top. During the time, the vertical direction of the travel belt 23 includes an upper belt section and a lower belt section. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com