Dry-type separation device and method for waste lead-acid storage battery broken materials

A lead-acid battery and separation device technology, applied in separation methods, solid separation, dispersed particle separation, etc., can solve problems such as low production efficiency and waste water generation, and achieve the effects of improving service life, reducing energy consumption, and reducing mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

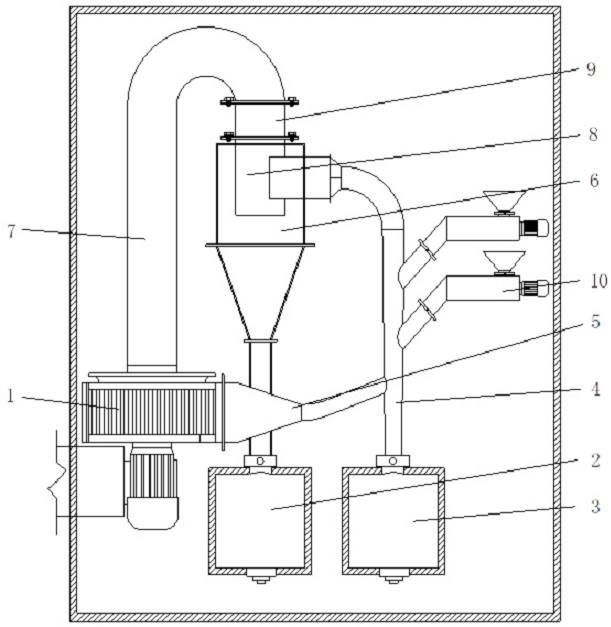

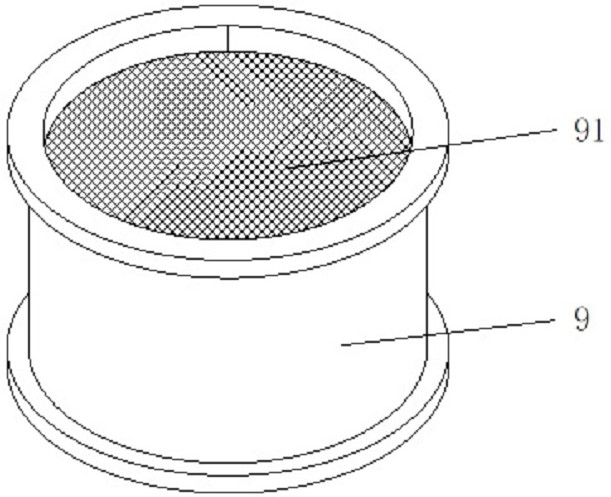

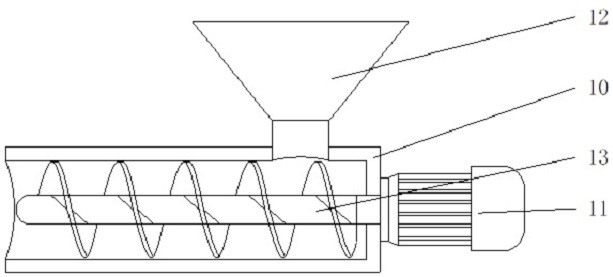

[0044] see Figure 1-Figure 2 , the present invention provides a technical solution: a dry-type separation device for waste lead-acid battery fragments, including a housing, a centrifugal fan 1, a plastic hopper 2 and a lead grain hopper 3, in this solution the centrifugal fan 1, the plastic The structure connecting the silo 2 and the lead pellet silo 3 is arranged in the housing, and the lead pellet silo 3 is fixedly connected with a separation pipe 4 whose lower end penetrates into the lead pellet silo 3, and the separation pipe 4 is set in a conical shape. This makes the separation effect of lead and plastic better. The output end of the centrifugal fan 1 is fixedly connected with the air delivery pipe 5. The side of the air delivery pipe 5 away from the centrifugal fan 1 penetrates into the separation pipe 4. The outer surface of the separation pipe 4 There are two crushed material push pipes 10 fixedly connected respectively, and the side of the two crushed material push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com