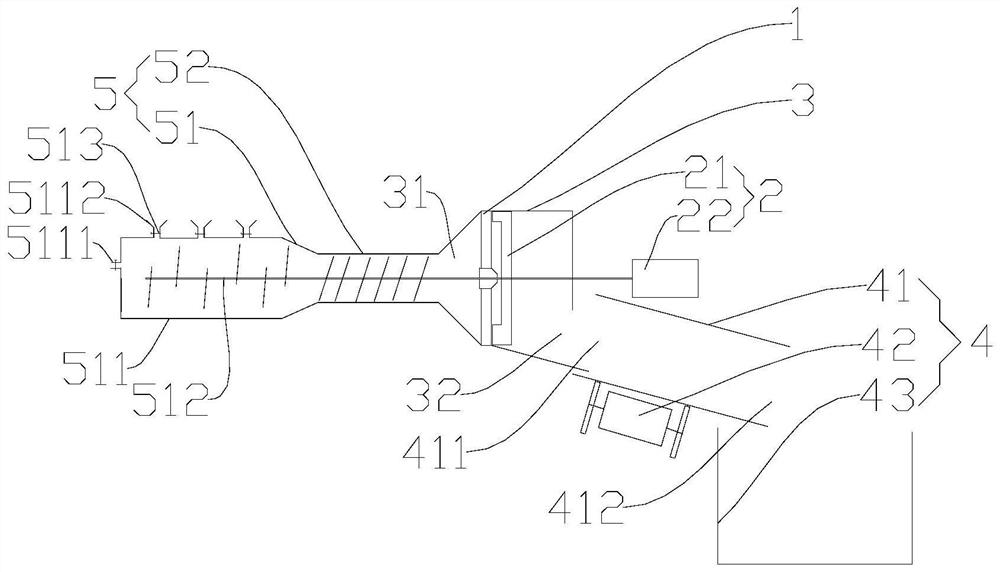

Granulation unit, grading granulation equipment and use method of grading granulation equipment

A kind of granulation equipment and granulation technology, which is applied in the field of material granulation, can solve the problems that the particle aspect ratio cannot be unified, the particle size aspect ratio cannot be adjusted, and the particle size cannot meet the gradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

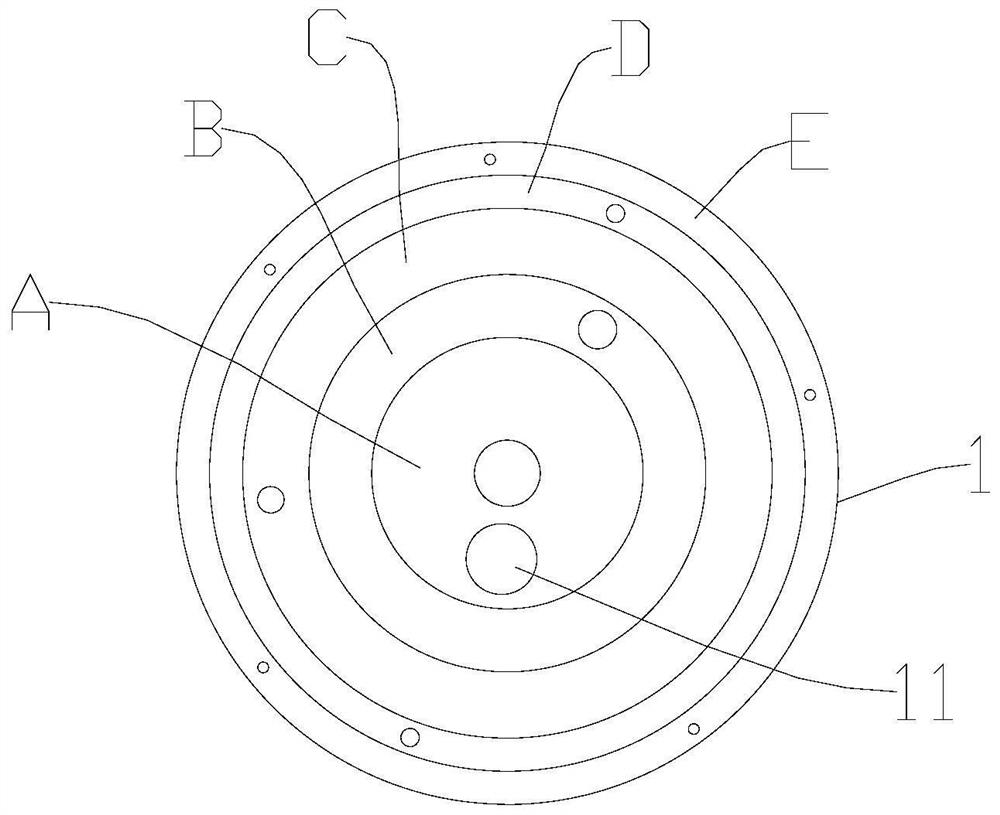

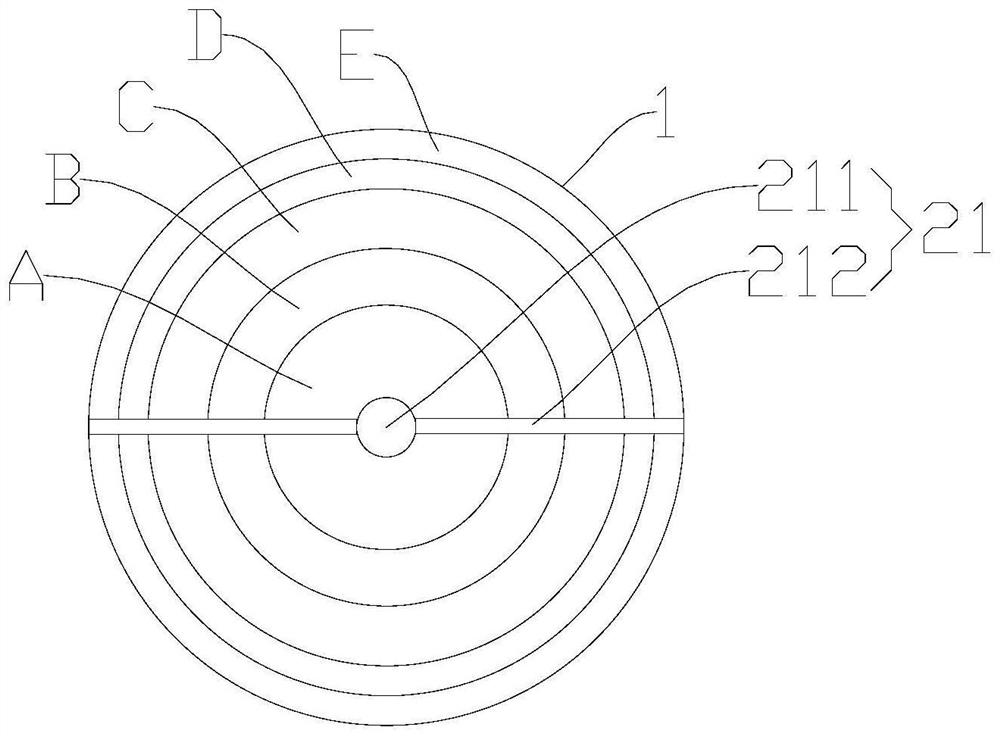

Embodiment 1

[0081] Select the representative construction industry standard "JTG / T F20-2015 Technical Rules for Road Pavement Base Construction" in the pavement base C-B-1 gradation design requirements, and its specific gradation is shown in Table 1. Since artificial aggregates mainly replace natural aggregates with medium and coarse particle sizes, it is necessary to set a level of fine aggregates to participate in the gradation design. The gradation of this fine aggregate can be obtained directly from natural stone mills, so it is not specific. Since the synthetic gradation is composed of artificial aggregate and fine aggregate, the gradation of artificial aggregate can be calculated under the conditions that both the synthetic gradation and the fine aggregate gradation are given. According to Table 1, the particle size of the aggregate and the mixing ratio of the aggregate in each particle size range can be determined, so as to calculate the size range of each extrusion hole 11 and the...

Embodiment 2

[0094] Select the representative construction industry standard "JTG / T F20-2015 Technical Rules for Road Pavement Base Construction" in the pavement base C-C-3 gradation design requirements, and its specific gradation is shown in Table 4. Since artificial aggregates mainly replace natural aggregates with medium and coarse particle sizes, it is necessary to set a level of fine aggregates to participate in the gradation design. The gradation of this fine aggregate can be obtained directly from natural stone mills, so it is not specific. Since the synthetic gradation is composed of artificial aggregate and fine aggregate, the gradation of artificial aggregate can be calculated under the conditions that both the synthetic gradation and the fine aggregate gradation are given. According to Table 4, the particle size of the aggregate and the mixing ratio of the aggregate in each particle size range can be determined, so as to calculate the size range of each extrusion hole 11 and the...

Embodiment 3

[0107] Select the representative construction industry standard "JTG / T F20-2015 Technical Rules for Road Pavement Base Construction" in the AC-25 gradation design requirements of the pavement base. The specific gradation is shown in Table 7. Since artificial aggregates mainly replace natural aggregates with medium and coarse particle sizes, it is necessary to set a level of fine aggregates to participate in the gradation design. The gradation of this fine aggregate can be obtained directly from natural stone mills, so it is not specific. Since the synthetic gradation is composed of artificial aggregate and fine aggregate, the gradation of artificial aggregate can be calculated under the conditions that both the synthetic gradation and the fine aggregate gradation are given. According to Table 7, the particle size of the aggregate and the mixing ratio of the aggregate in each particle size range can be determined, so as to calculate the size range of each extrusion hole 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com