Low-disturbance soil treatment device

A low-disturbance, soil technology, used in soil-lifting machinery, plant protection covers, agricultural machinery and implements, etc., can solve problems such as affecting plant growth, achieve uniform electric field distribution, improve treatment effects, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

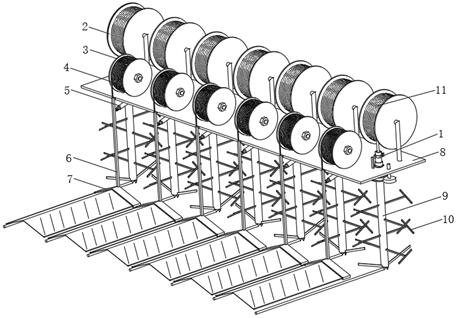

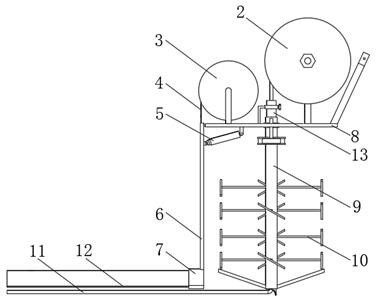

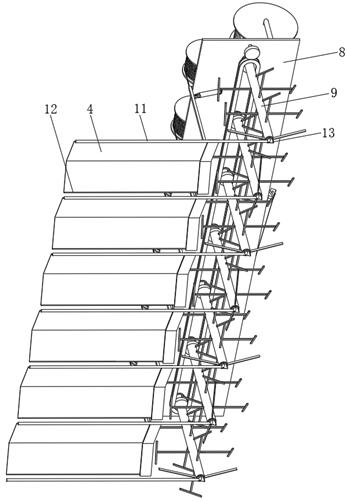

[0031] Example 1: Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 , this embodiment discloses a low-disturbance soil treatment device, including a support base 8, on which several crushing components are installed along the length direction of the support base 8, the working state of the low-disturbance soil treatment device is along the width direction of the support base 8 Move, the crushing assembly includes a circular insertion tube 13, a drive tube 9 mounted on the support base 8 and rotatable vertically, and a rotatable first storage tray 2 installed on the support base 8, and on the support base 8 A mounting hole is opened, and the inner wall of the mounting hole is connected to the outer upper part of the drive tube 9 through bearing rotation. The blind tube 11 is wound and accommodated on the first storage tray 2, and the insertion tube 13 is inserted into the drive tube 9 and inserted into the tube. Both ends of 13 protrude from the driv...

Embodiment 2

[0050] Embodiment two: if Figure 4 As shown, this embodiment discloses a low-disturbance soil treatment device, its structure is roughly the same as that of Embodiment 1, the difference is that the soil dividing plate 7 described in this embodiment includes an upper pinch plate 71, a lower pinch plate 72. The upper buckle plate 71 and the lower buckle plate 72 are connected together by buckles or bolts. The lower buckle plate 72 is provided with a receiving groove 74, and the receiving groove 74 is open at one end away from the forward direction.

[0051] Both ends of the width of the covering film 4 are provided with soft clamping strips 12 .

[0052] Both sides of the receiving groove 74 in the length direction are provided with long grooves 73 , and the two long grooves 73 gradually approach the lower end of the conduit 6 from far to near, and the long grooves 73 are adapted to the clamping strip 12 .

[0053] The working process and principle of this embodiment are:

[...

Embodiment 3

[0055] Embodiment three: as Figure 4 As shown, this embodiment discloses a low-disturbance soil treatment device, its structure is roughly the same as that of Embodiment 1, the difference is that this embodiment also includes a conductive plate 20 and a voltage regulating assembly 21, and the dead pipe 11 A wire 22 is provided, the negative terminal of the voltage regulation assembly 21 is electrically connected to the conductive plate 20, the positive terminal of the voltage regulation assembly 21 is electrically connected to the wire 22, and the voltage regulation assembly 21 is powered by the grid or vehicle power generation.

[0056] The voltage regulating component 21 is a common DC output voltage regulating device in the prior art, and its structure and internal circuit are common knowledge, and will not be repeated here.

[0057] Preferably, the wire 22 can slide in the dead leg 11 .

[0058] The working process and principle of this embodiment are:

[0059] Pour wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com