Controllable combined reactor

A reactor and combined technology, applied in transformer/inductor housing, transformer/inductor cooling, chemical instruments and methods, etc., can solve the problems of inconvenient maintenance and replacement of parts, inability to improve heat dissipation efficiency, difficulty in quick disassembly, etc. problems, to achieve the effect of easy actual operation, easy follow-up maintenance and replacement of parts, and convenient and quick disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

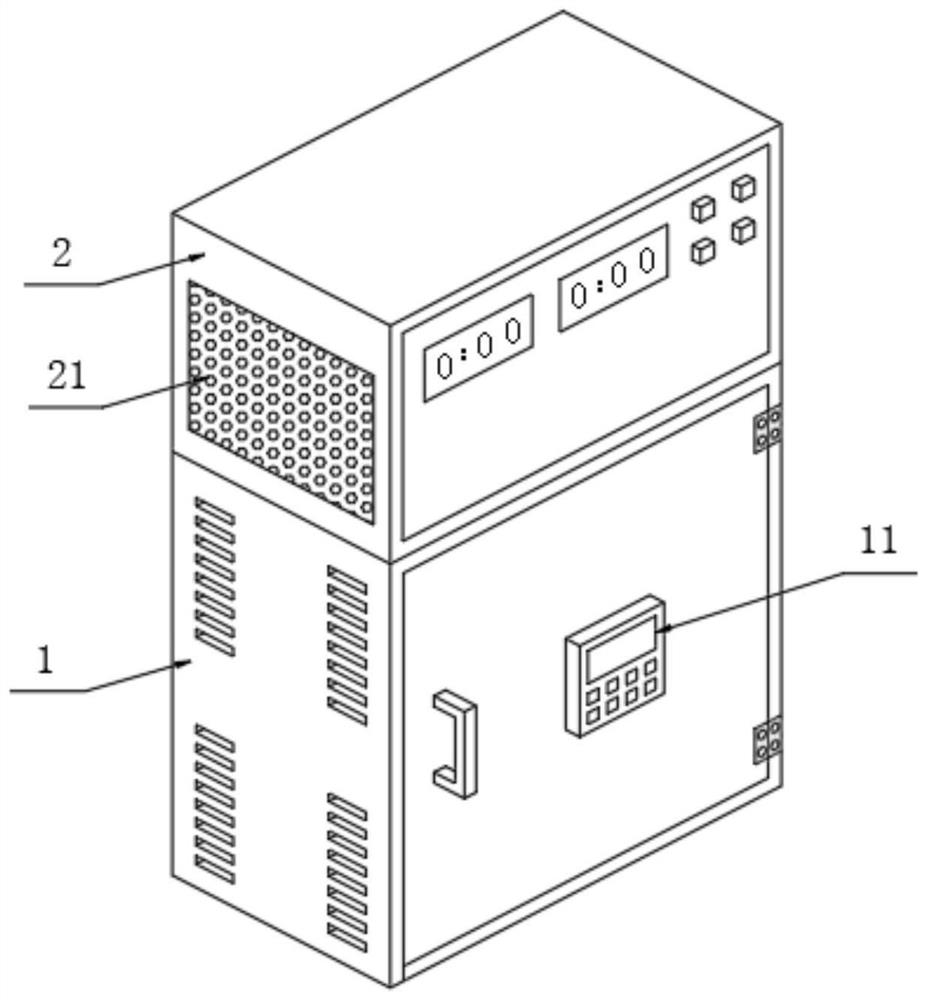

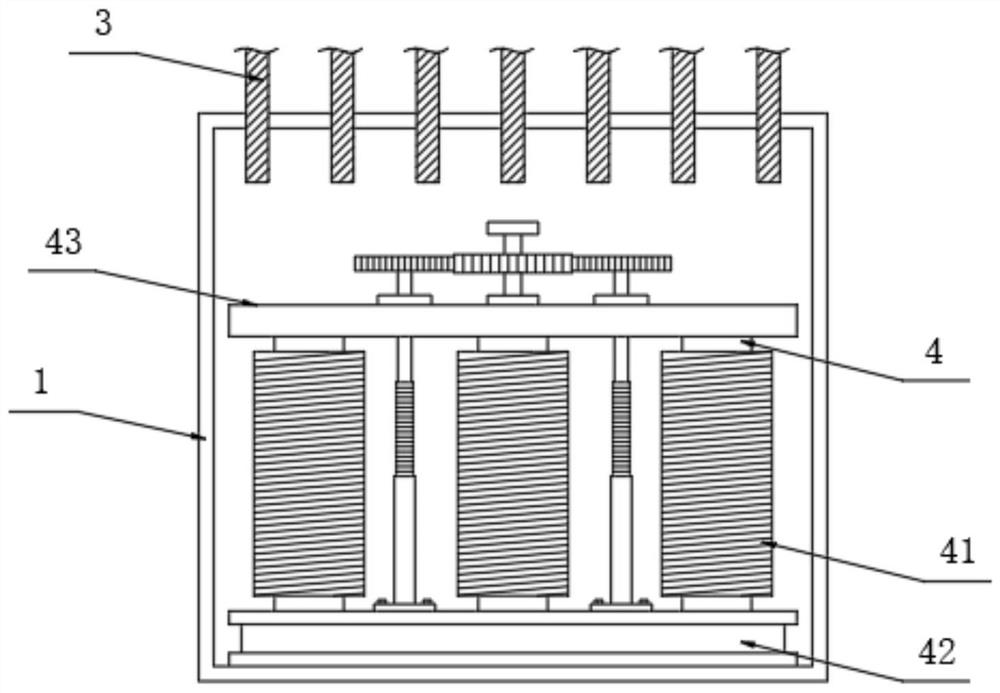

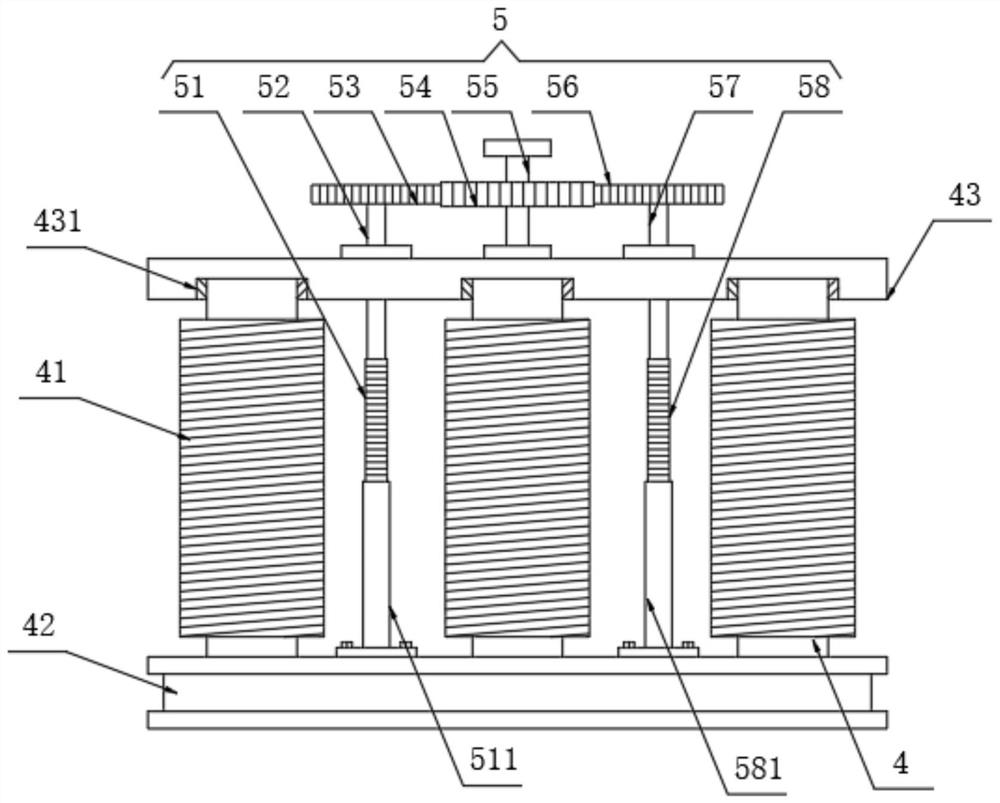

[0027] see Figure 1~5 , a controllable combined reactor, including a protective box 1, the front surface of the protective box 1 is fixed with a controller 11, and the inside of the protective box 1 is installed with an I-beam 42, and the top of the I-beam 42 is fixed with three A rectangular iron core 4, the outsides of the three rectangular iron cores 4 are all wound with inductance coils 41, and the top of the three rectangular iron cores 4 is equipped with a metal baffle 43, and the lower surface of the metal baffle 43 is equidistantly provided with three Limiting groove 431, the rectangular iron core 4 is compatible with the limiting groove 431, the top of the rectangular iron core 4 is movably inserted into the inside of the limiting groove 431, the top of the protective box 1 is fixedly connected with the cooling box 2, the cooling box 2 Ventilation nets 21 are provided on both sides of the protective box 2, and a blower mechanism 6 is installed inside the heat dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com