Multifunctional dewatering and drying equipment for agricultural grain processing machinery

A technology for processing machinery and drying equipment, applied in lighting and heating equipment, drying chambers/containers, drying solid materials, etc., can solve problems such as waste of air-drying space, scorched grains, fires, etc., to avoid occupying equipment resources and improve Effect of improving drying efficiency and working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

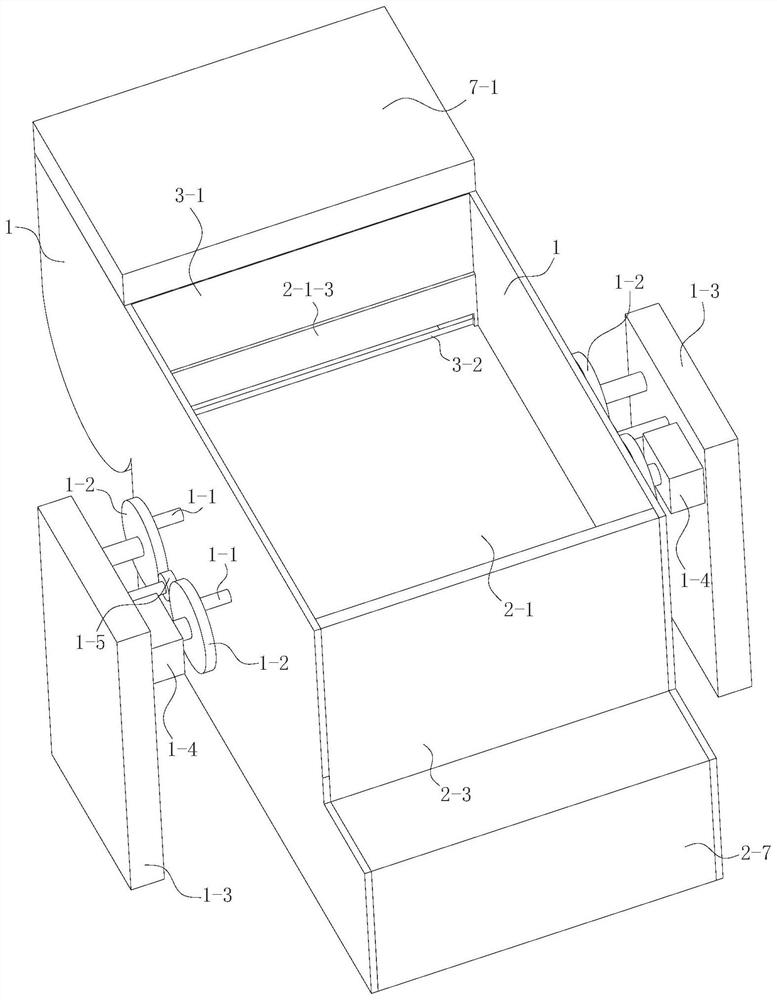

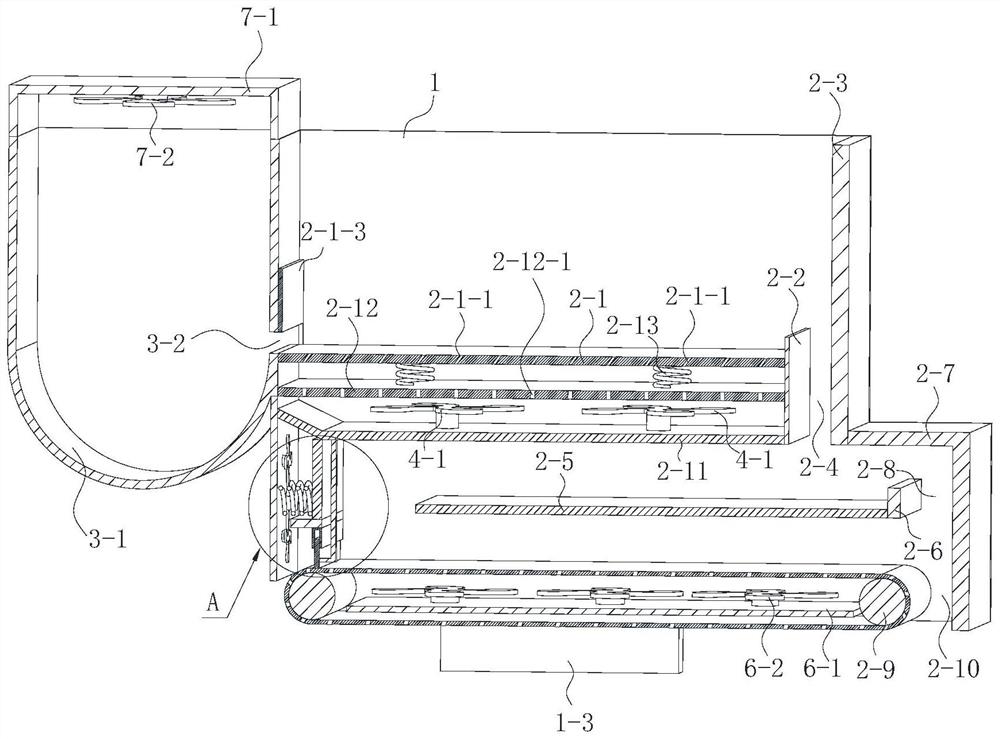

[0025] see Figure 1-5 , the present invention provides a technical solution: a multifunctional dehydration and drying equipment for agricultural grain processing machinery, including two symmetrically arranged mounting plates 1, and a feeding box and a drying mechanism are respectively fixedly connected between the mounting plates 1, so that The feed box is connected with the drying mechanism; two mounting plates 1 are connected to the same position on the side away from the feed box with two identical load-bearing shafts 1-1, and the load-bearing shafts 1-1 are The runner 1-2 is fixedly connected to the eccentricity; one runner 1-2 on the same mounting plate 1 is connected to the support plate 1-3 in rotation, and the other runner 1-2 is fixedly connected to the motor 1-4, The motor 1-4 is fixedly connected with the support plate 1-3, and the motor is used to drive the runner 1-2 to rotate, and drives the mounting plate 1 to perform a circular motion in a horizontal state, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com