Deep cleaning construction method for channel side slope

A construction method and slope technology, applied in the field of channel slope deep cleaning construction, can solve the problems of small coverage area, influence on cleaning effect, cumbersome operation, etc., achieve the effect of large jet coverage area, enhanced cleaning effect, and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

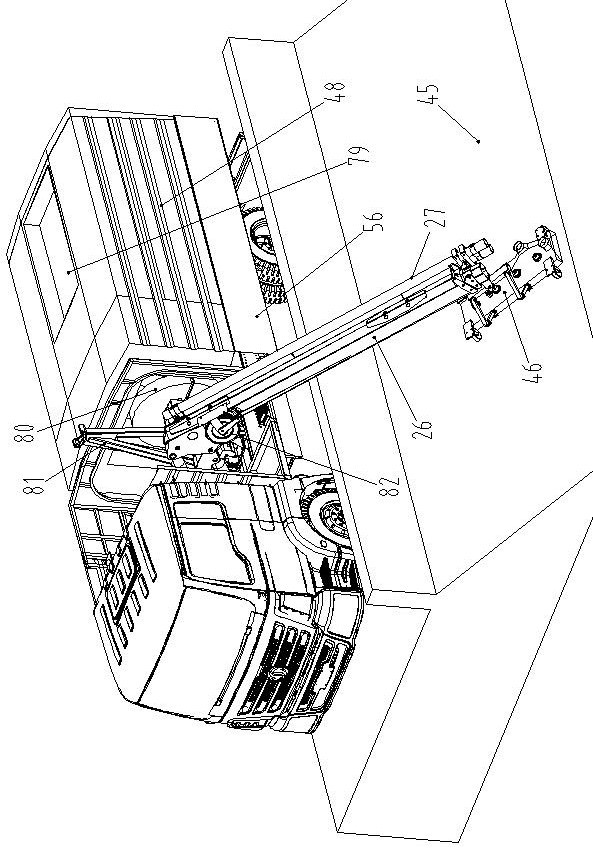

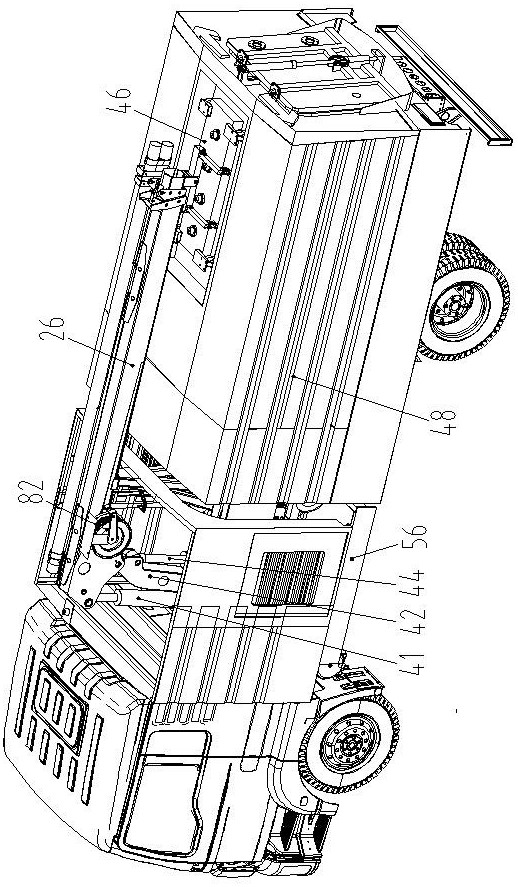

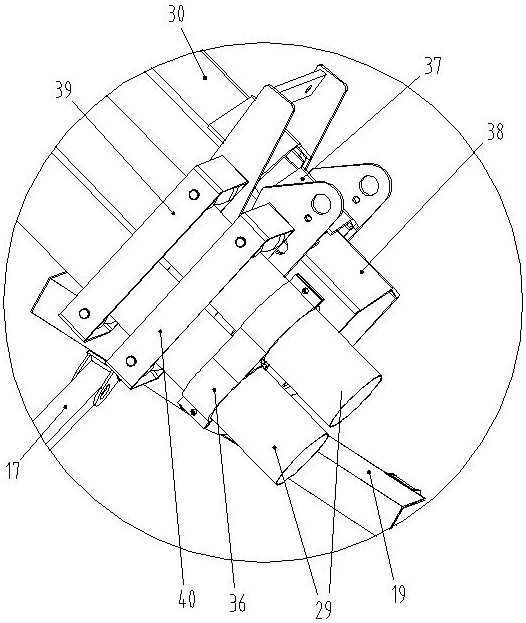

[0068] Such as Figure 1-Figure 13 As shown, the channel slope depth cleaning construction method of the present invention adopts a new type of multifunctional vehicle for deep cleaning of the channel slope. The truck 56 is equipped with a transfer case device, a hydraulic system, a rotary and luffing drive mechanism, a clean water tank (not shown), a high-pressure water pump, a negative pressure fan 80, and a sewage collection box 49. After the sewage collection box 49 The side is provided with a box door 57 and an unloading power drive mechanism for controlling the opening and closing of the box door 57. The transfer case device is installed between the gearbox and the drive axle on the chassis, and the PTO power port on the transfer case is connected to the hydraulic system. The hydraulic pump transmission connection, the hydraulic system is respectively connected with the unloading power drive mechanism, the multi-stage hydraulic telescopic arm 26, the rotary swing drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com