Pile net composite foundation round chamfer pile cap and construction method and design method thereof

A technology of composite foundation and design method, applied in the direction of foundation structure engineering, sheet pile wall, road, etc., can solve the problems of inability to complete the drainage consolidation process in time, low permeability coefficient and compressive modulus, large settlement of soil between piles, etc. Achieve the effect of avoiding fracture and damage of geogrid, reducing additional tensile strain and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

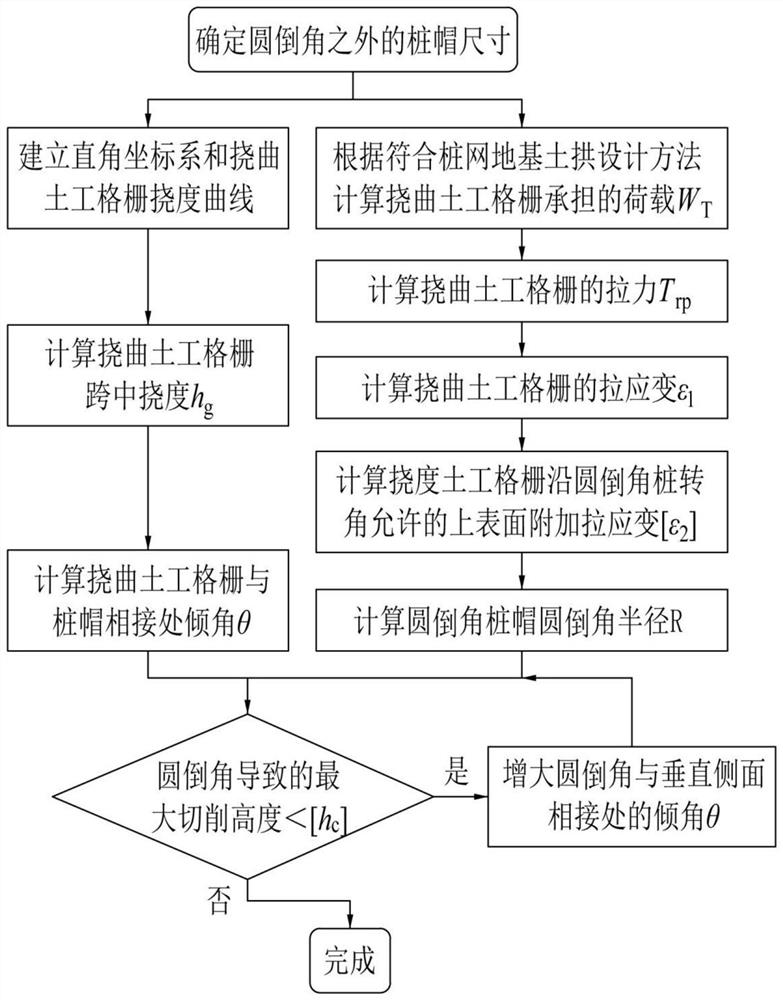

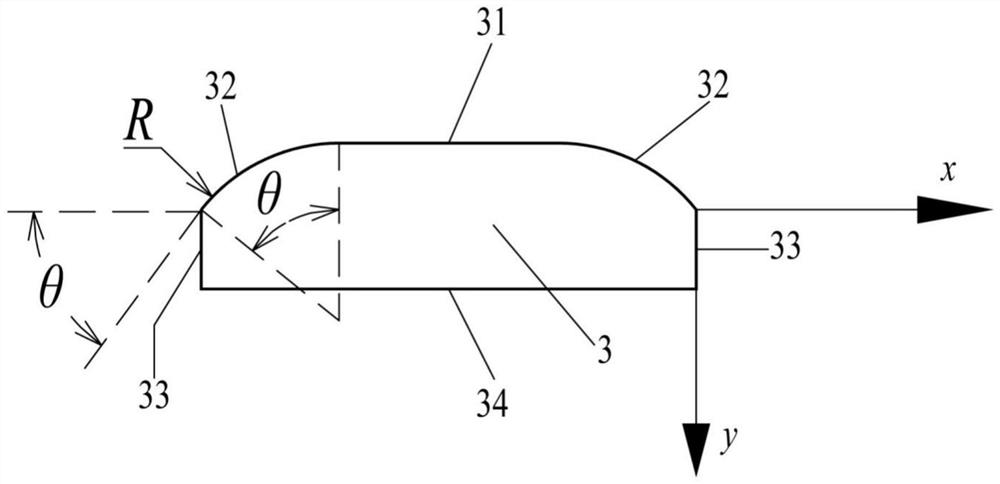

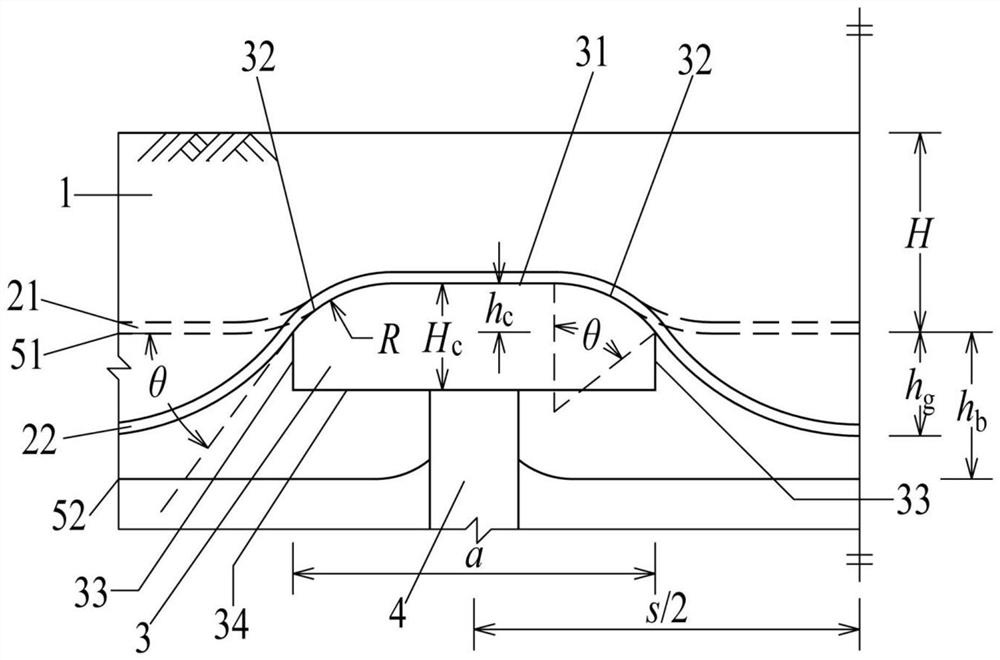

[0069] Embodiment: A round chamfer design method of pile cap with round chamfer on pile net composite foundation, including the design method of the round chamfer center angle θ of the pile cap body and the design method of the arc radius R of the round chamfer.

[0070] (1) The specific design steps of the central angle θ of the rounded chamfer are as follows:

[0071] Step 1, determine the width a=1.6m and height H of the pile cap except the fillet c =0.4m, pile spacing s=2.5m. Establish a rectangular coordinate system, the origin is located at the intersection of the deflected geogrid and the vertical side of the rounded chamfered pile cap, the horizontal axis x points outward from the center of the pile cap, and the vertical axis y is vertically downward, and the deflected geogrid is placed on the rounded chamfered pile The deflection line between the caps is

[0072] Step 2, the maximum allowable strain of the geogrid [ε] = 2%, and the mid-span deflection of the defle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com