High-purity metal purification device and metal purification method

A purification method and high-purity technology, applied in the field of high-purity metal purification devices, can solve the problems of not easy separation, low impurity enrichment effect, remolding of impurity crystal nucleus, etc. High impurity enrichment effect and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

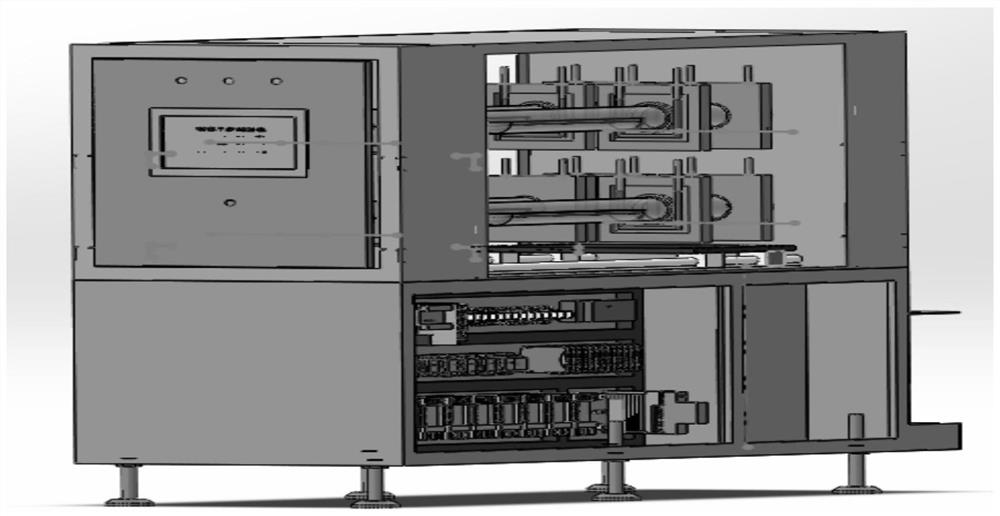

Image

Examples

Embodiment

[0057] After placing the 5N tellurium raw material in the quartz boat in the quartz tube, after exhausting all the air in the quartz tube, pass in hydrogen for protection.

[0058] A zone melting includes the following steps:

[0059] S1, even leveling: the number of zone melting is 1 time, the zone melting speed is 100mm / h, the width of the melting zone is 120mm, and the gas flow rate is 300ml / min;

[0060] S2, express train: the number of zone melting is 4 times, the zone melting speed is 80mm / h, the width of the melting zone is 100mm, and the gas flow rate is 200ml / min;

[0061] S3. Slow train: the number of zone melting times is 2, the zone melting speed is 60mm / h, the width of the melting zone is 80mm, and the gas flow rate is 200ml / min, thereby obtaining 6N tellurium.

[0062] Secondary zone melting includes the following steps:

[0063] S1, even leveling: the number of zone melting is 1 time, the zone melting speed is 100mm / h, the width of the melting zone is 120mm, a...

Embodiment 2

[0067] After placing the 5N tellurium raw material in the quartz boat in the quartz tube, after exhausting all the air in the quartz tube, pass in argon gas for protection.

[0068] A zone melting includes the following steps:

[0069] S1. Uniformity: the number of zone melting is 1 time, the zone melting speed is 100mm / h, the width of the melting zone is 100mm, and the gas flow rate is 300ml / min;

[0070] S2, express train: the number of zone melting is 4 times, the zone melting speed is 80mm / h, the width of the melting zone is 80mm, and the gas flow rate is 200ml / min;

[0071] S3. Slow train: the number of zone melting is 2 times, the zone melting speed is 60mm / h, the width of the melting zone is 50mm, and the gas flow rate is 200ml / min, so as to obtain 6N tellurium.

[0072] Secondary zone melting includes the following steps:

[0073] S1. Uniformity: the number of zone melting is 1 time, the zone melting speed is 100mm / h, the width of the melting zone is 100mm, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com