Gas supply system of gasification furnace

A technology of gas supply system and gasifier, which is applied in the field of gasification, can solve the problems of lack of adjustment of gas supply pressure, affect the use of gas supply of gas equipment, and it is difficult to meet the demand of gas supply pressure of gas equipment, so as to achieve the guarantee Requirements, increased air supply pressure, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

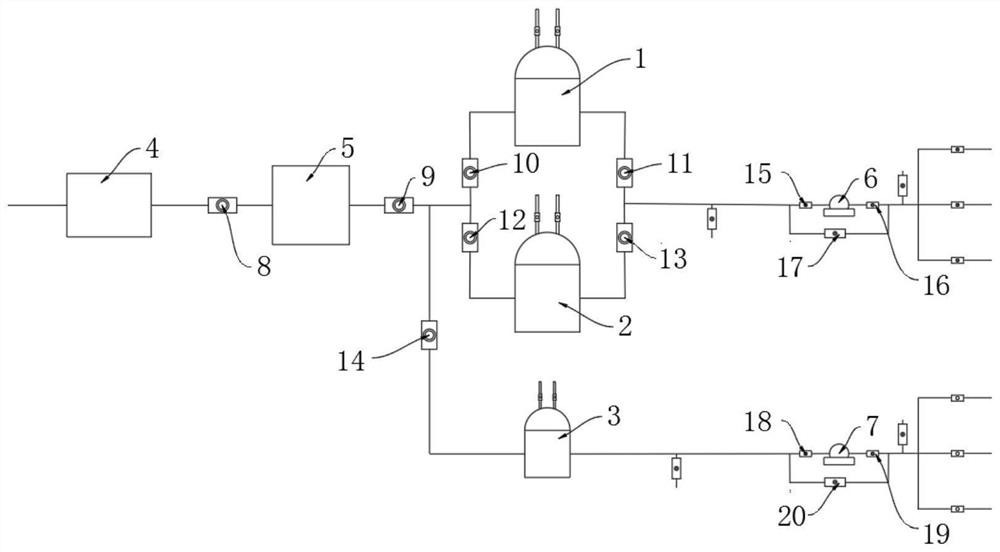

[0034] Please refer to figure 1 As shown, a gas supply system for a gasifier, the gas supply system includes: a main continuous gas supply tank 1 and a standby continuous gas supply tank 2 connected in parallel through a gas supply pipeline, the main continuous gas supply tank 1 and the standby continuous air supply tank 2 are both used to supply gas to the continuous gas supply equipment; the intermittent gas supply tank connected in parallel with the main continuous gas supply tank 1 and the standby continuous gas supply tank 2 through the gas supply pipeline Gas tank 3, intermittent gas supply gas storage tank 3 is used to supply gas to intermittent gas supply equipment; nitrogen generator 4, nitrogen generator 4 is used to supply continuous gas to main continuous gas storage tank 1, standby continuous gas supply and storage The tank 2 and the intermittent gas supply tank 3 provide high-pressure nitrogen; the water circulation device 5 connected in series with the nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com