Plastering gypsum mortar and preparation method thereof

A technique for plastering gypsum and mortar, which is applied in the field of plastering gypsum mortar and its preparation, can solve the problems of low coating rate of plastering gypsum mortar and the like, and achieves the effects of good thermal insulation performance, lower production cost and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

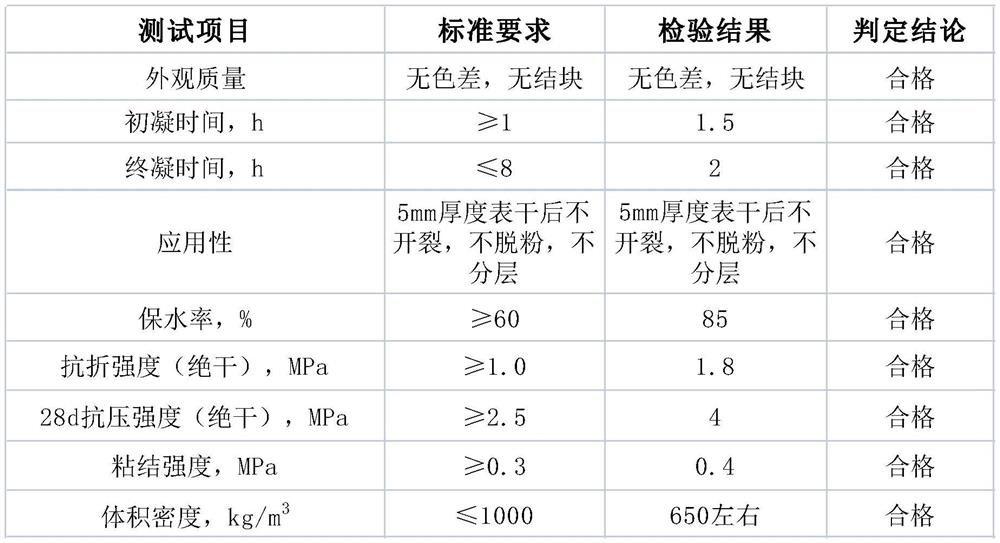

Embodiment 1

[0017] A plastering gypsum mortar, comprising components and the weight percentage of the components are: 75% of hemihydrate gypsum, 1% of vermiculite powder, 7.55% of heavy calcium powder, 15% of vitrified microbeads, 1% of ash calcium, cellulose Ether 0.2%, starch ether 0.05%, air-entraining agent 0.03%, retarder 0.12%, thixotropic agent 0.05%.

[0018] Specifically, the hemihydrate gypsum is β-type hemihydrate gypsum, the fineness of the vermiculite powder is 30-50 mesh, the fineness of the heavy calcium powder is 200 mesh, and the fineness of the vitrified microbeads is The degree is 70-90 mesh, the model of the cellulose ether is 4155P, and the model of the starch ether is A850.

[0019] Its preparation method comprises the following steps:

[0020] S1, according to the formula of above-mentioned a kind of plastering gypsum mortar, weigh each component for subsequent use;

[0021] S2, then add the hemihydrate gypsum, heavy calcium, gray calcium, cellulose ether, starch ...

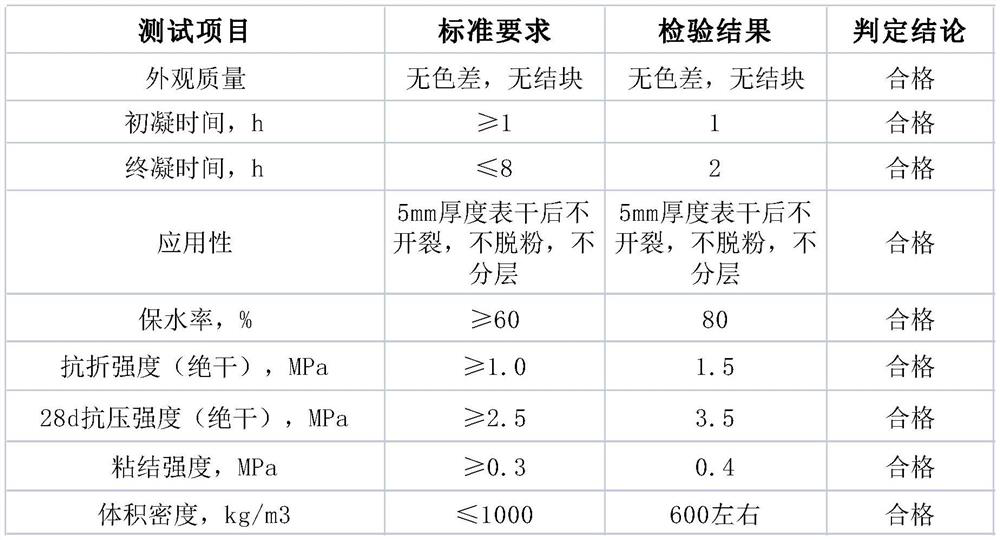

Embodiment 2

[0027] A plastering gypsum mortar, comprising components and the weight percentage of the components are: 70% of hemihydrate gypsum, 1.05% of vermiculite powder, 9.25% of heavy calcium powder, 18% of vitrified microbeads, 1.15% of lime calcium, cellulose Ether 0.25%, starch ether 0.06%, air-entraining agent 0.04%, retarder 0.14%, thixotropic agent 0.06%.

[0028] Specifically, the hemihydrate gypsum is β-type hemihydrate gypsum, the fineness of the vermiculite powder is 30-50 mesh, the fineness of the heavy calcium powder is 200 mesh, and the fineness of the vitrified microbeads is The degree is 70-90 mesh, the model of the cellulose ether is 4155P, and the model of the starch ether is A850.

[0029] Its preparation method comprises the following steps:

[0030] S1, according to the formula of above-mentioned a kind of plastering gypsum mortar, weigh each component for subsequent use;

[0031] S2, then add the hemihydrate gypsum, heavy calcium, gray calcium, cellulose ether,...

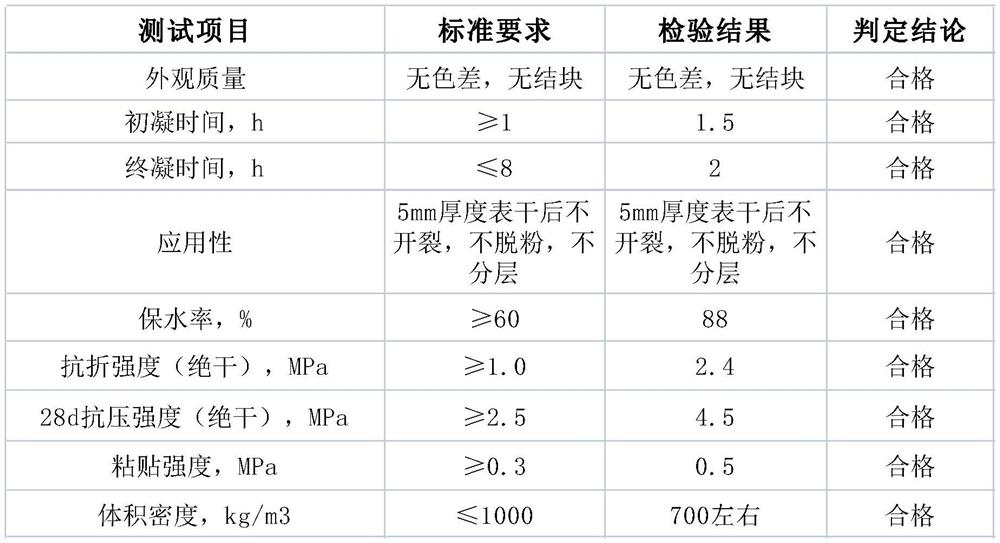

Embodiment 3

[0037] A plastering gypsum mortar, comprising components and the weight percentage of the components are: 80% of hemihydrate gypsum, 0.95% of vermiculite powder, 5.04% of heavy calcium powder, 13% of vitrified microbeads, 0.65% of lime calcium, cellulose Ether 0.15%, starch ether 0.04%, air-entraining agent 0.02%, retarder 0.11%, thixotropic agent 0.04%.

[0038] Specifically, the hemihydrate gypsum is β-type hemihydrate gypsum, the fineness of the vermiculite powder is 30-50 mesh, the fineness of the heavy calcium powder is 200 mesh, and the fineness of the vitrified microbeads is The degree is 70-90 mesh, the model of the cellulose ether is 4155P, and the model of the starch ether is A850.

[0039] Its preparation method comprises the following steps:

[0040] S1, according to the formula of above-mentioned a kind of plastering gypsum mortar, weigh each component for subsequent use;

[0041] S2, then add the hemihydrate gypsum, heavy calcium, gray calcium, cellulose ether,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com