Segment crane and hoisting method

A segment and crane technology, which is used in cranes, earth-moving drilling, transportation and packaging, can solve the problem that segment cranes cannot adapt to large-slope shield construction, and achieves improved hoisting efficiency and construction safety factor. The effect of high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

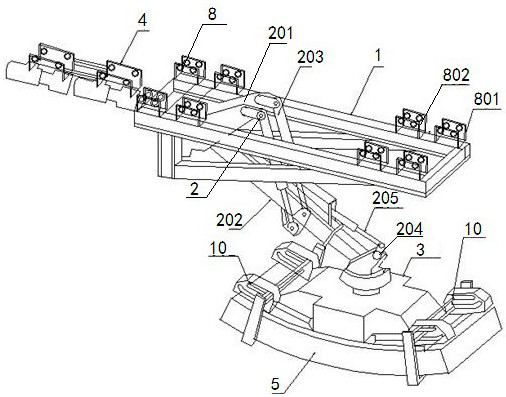

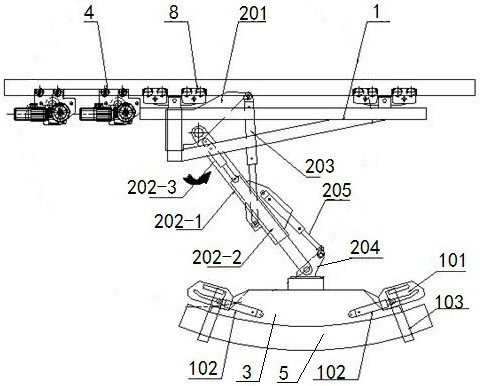

[0030] Embodiment 3, a hoisting method of the large-slope segment crane as described in Embodiment 2, the steps are as follows:

[0031] S1: The walking frame body 1 drives the entire segment crane to move to the top of the segment quick release device.

[0032]S2: The lifting cylinder 203 of the inclination adjustment mechanism 2 and the rotating cylinder 205 cooperate to adjust the height and angle of the vacuum suction cup 3 through the telescopic arm 202 and the swing plate 204, so that the vacuum suction cup 3 is in a state parallel to the segment 5, which can be inclined It can also be in an inclined state, which is convenient for fast grabbing of segments.

[0033] S3: The vacuum suction cup 3 is adjusted to an appropriate angle, gradually moves to the segment, and absorbs and grasps the segment on the segment quick release device.

[0034] S4: Then the oscillating oil cylinder 102 of the anti-falling mechanism 10 drives the closed-loop bracket 103 to swing, so that th...

Embodiment 5

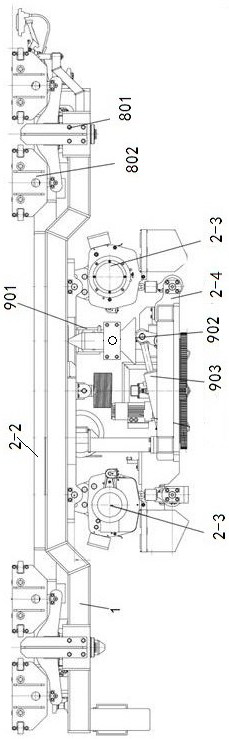

[0040] Embodiment 5, a hoisting method of the large-slope segment crane as described in Embodiment 4, the steps are as follows:

[0041] S1: The walking frame body 1 drives the entire segment crane to move above the segment quick-release device; the longitudinal driving mechanism drives the trolley frame to fine-tune left and right on the walking frame body, so that the vacuum suction cup can be accurately located at the lifting point.

[0042] S2: The inclination adjustment mechanism 2 adjusts the height and angle of the vacuum suction cup 3 through the chain hoist, so that the vacuum suction cup 3 is parallel to the segment, that is, the vacuum suction cup 3 and the segment are in a horizontal state, which is convenient for quickly grabbing the segment.

[0043] S3: The vacuum suction cup 3 is adjusted to an appropriate angle, gradually moves to the segment, and absorbs and grasps the segment on the segment quick release device.

[0044] S4: Then the swing cylinder 102 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com