Steel pipe drilling equipment

A technology for drilling equipment and steel pipes, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., which can solve the problems of easy fatigue of staff, unfavorable mass production, and reduced work efficiency, etc., to achieve The effect of improving service life, realizing mass production and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

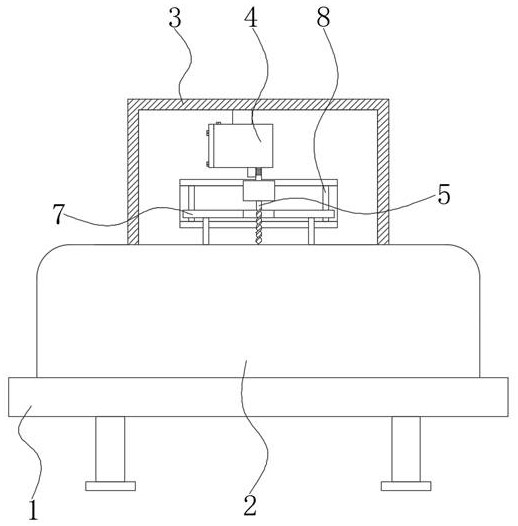

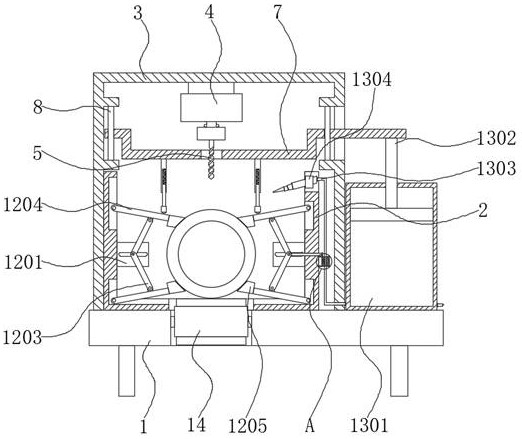

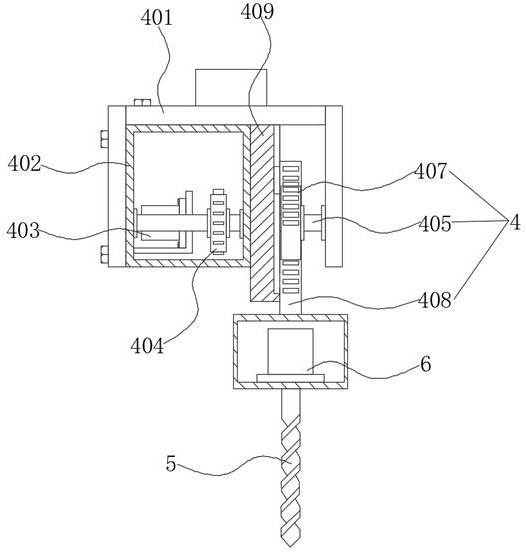

[0027] Example: see Figure 1-7 , a steel pipe drilling equipment, including a base 1, a mounting seat 2 and a bracket 3 arranged on the top of the base 1, a transmission mechanism 14 is arranged inside the base 1, and the transmission mechanism 14 is specifically a conveyor belt, and the top of the inner wall of the bracket 3 is provided with a drive Mechanism 4, the bottom of the driving mechanism 4 is arranged on the drill bit 5, and the internal movement of the support 3 is provided with a pressing plate 7, and the inside of both ends of the pressing plate 7 is sleeved with a vertical rod 8, and the two ends of the bottom of the pressing plate 7 are provided with a connecting cylinder 9. The inside of the cylinder 9 is provided with a return spring 11, the bottom of the return spring 11 is provided with a pressing rod 10, the inside of the mounting seat 2 is provided with a pressing mechanism 12, and one end of the top of the base 1 is provided with a cooling mechanism 13; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com