Waste round steel straightening process for building

A construction and straightening technology, applied in dryers, drying, devices for coating liquid on surfaces, etc., to avoid brush leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

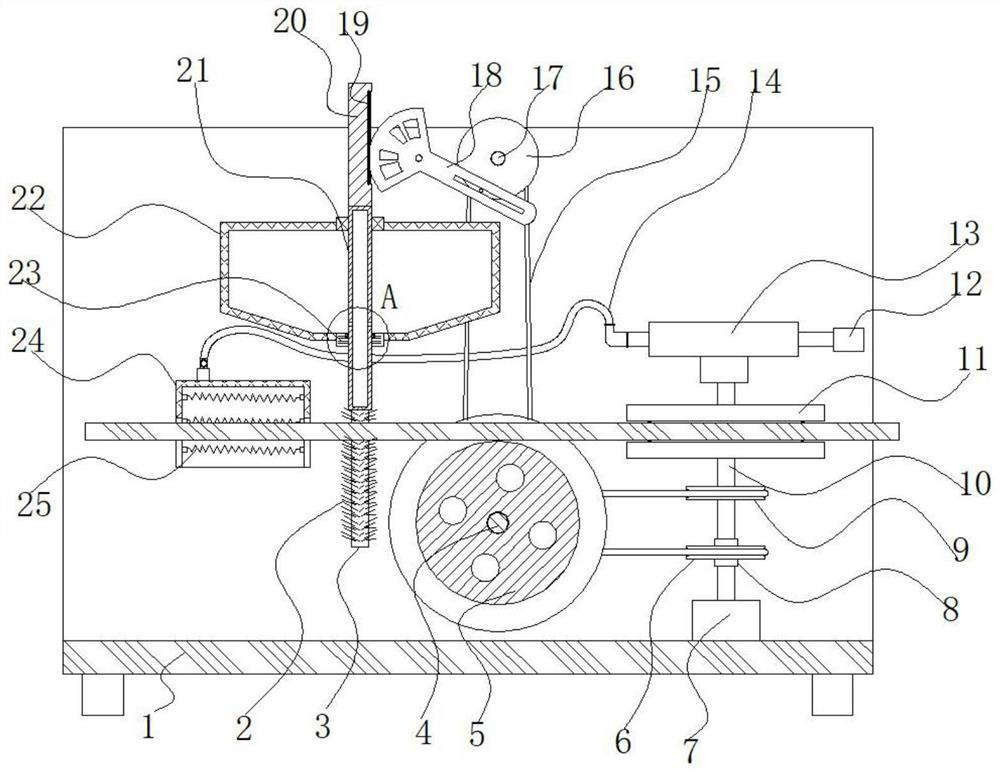

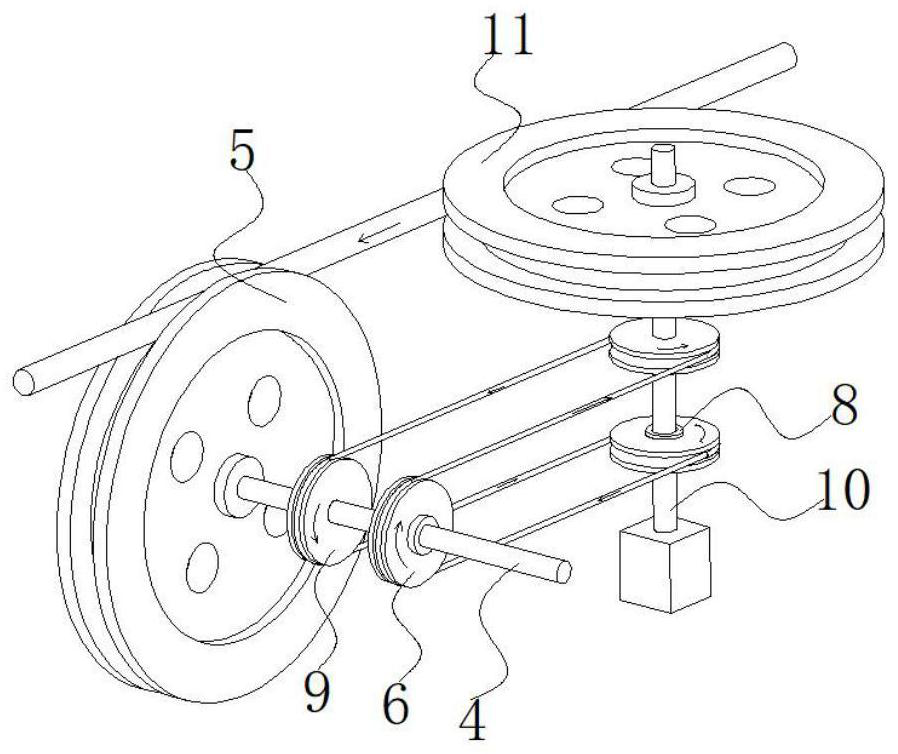

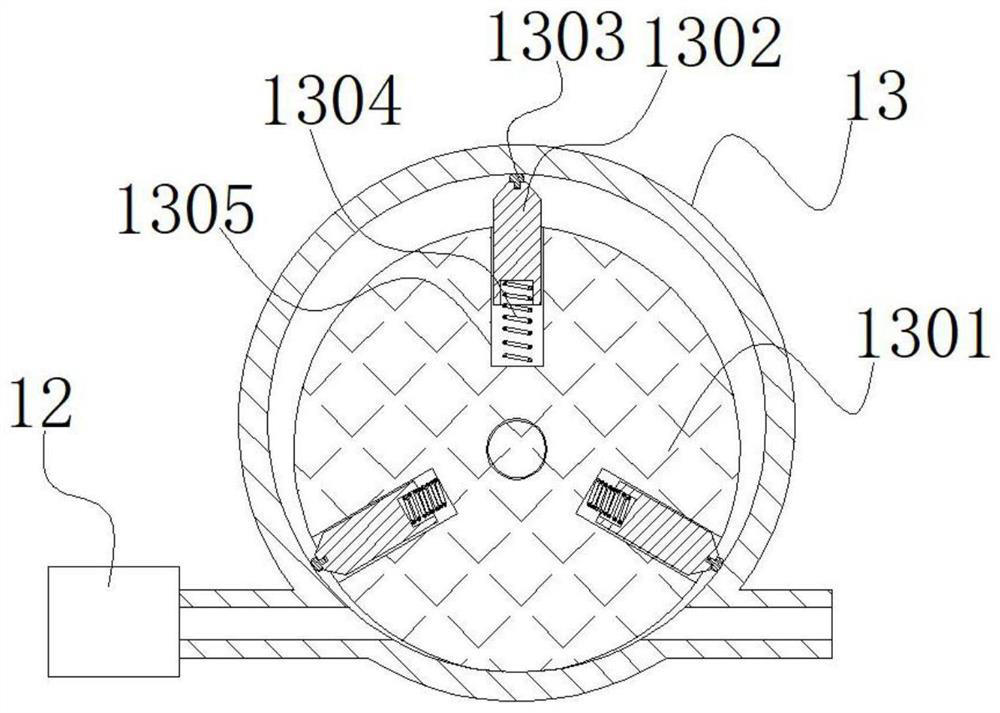

[0026] refer to Figure 1-5, a process for straightening scrap round steel for construction, comprising a support base 1 whose bottom is fixed on the ground with a U-shaped structure through anchor bolts, and a drive motor 7 is fixed near the middle of the groove bottom of the support base 1, and The top of the output shaft of the driving motor 7 is fixed with a transmission rod 10 through a coupling, and the vertical inner walls on both sides of the support base 1 are rotatably connected with a transmission rod 2 4 perpendicular to the different planes of the transmission rod, and the transmission rod 2 4 and the peripheral outer wall of the transmission rod 10 are respectively key-connected with straightening wheel two 5 and straightening wheel one 11, and the peripheral outer walls of the described straightening wheel two 5 and straightening wheel one 11 are all provided with sections that are U-shaped. Annular groove, the distance between the both sides inner wall of annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com