Apparatus for coating textiles

A coating device and textile technology, applied in the direction of the surface coating liquid device, coating, etc., can solve the problems of uncontrollable glue amount, poor coating effect, poor gap effect, etc., to improve the coating effect, The effect of improving the scope of application and good coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

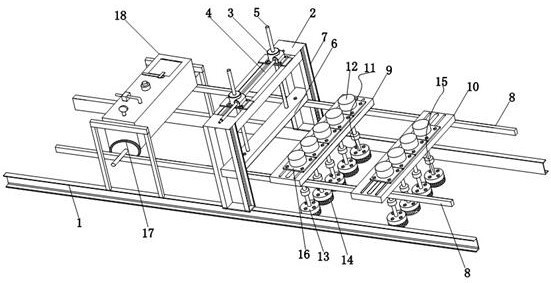

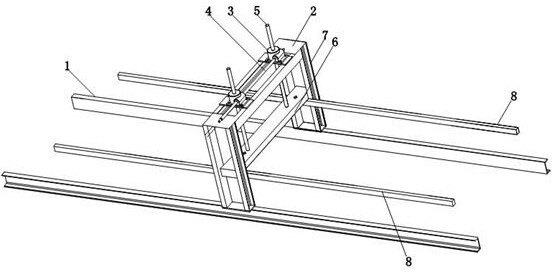

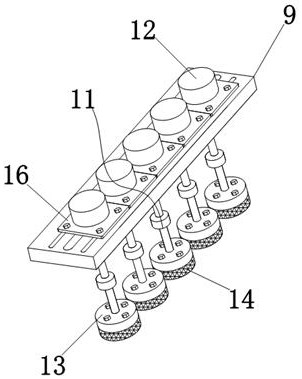

[0028] Such as Figure 1-8As shown, a coating device for textiles includes a frame 1, a first beam 2 is arranged on the frame 1, and two groups of matched worm gears 3 and worms 4 are symmetrically arranged on the first beam 2, and the worm gears 3 are matched and connected. There is a screw 5, and the lower part of the screw 5 is movably connected to the second beam 6, and the two are movably connected through the adjusting nut. By adjusting the movable nut, the distance between the first beam 2 and the second beam 6 can be adjusted. When in use, the drive motor drives the reducer, and the reducer The worm 4 is driven to rotate through the connector, the worm 4 drives the worm wheel 3 to rotate, and the worm wheel 3 drives the screw 5 to move up and down. By controlling the forward rotation and reverse rotation of the driving motor, the screw 5 can drive the second beam 6 to rise or fall; the second beam 6 two ends are connected with a set of stand 7 vertically fixed on the t...

Embodiment 2

[0030] When a coating device for textiles is working: when the textiles pass under the brush roller 17, according to the elasticity and material of the textiles, press the "down" button of the drive motor to connect the brush roller 17 with the front glue brushing device 11 and the back brush Adjust the glue device 15 to a suitable height so that the brush roller 17, the brush 14 of the front glue brushing device 11, and the hair brush 14 of the back glue brushing device 15 are fully in contact with the surface of the textile, and press the "start" of the solenoid valve 25 Button and air pump "start", "intake" button, air enters the glue storage box 18 and pressurizes the glue in the glue storage box 18, speeds up the speed of the glue in the box flowing out from the bottom through hole 19, and makes the brush The roller 17 is fully soaked in the glue, and the brush roller 17 is in full contact with the surface of the textile. While being driven by the advancing textile to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com